Designed for high yields with energy saving technology.

Technology & Experience

Through our experience of having installed spray dryers as large as 10 meters in drying chamber diameter (processing capacity of 10t /h), we provide the know-how of how to obtain a high yield while saving energy. We also offer a variety of automated systems such as a fully-automated operation system, CIP cleaning system and integral communication system with other plants.

Flexible design

All the atomization modes can be selected with a variety of options. The D-Series can also be configured to operate as both a spray cooler and spray dryer, as well as open-cycle and closed-cycle systems.

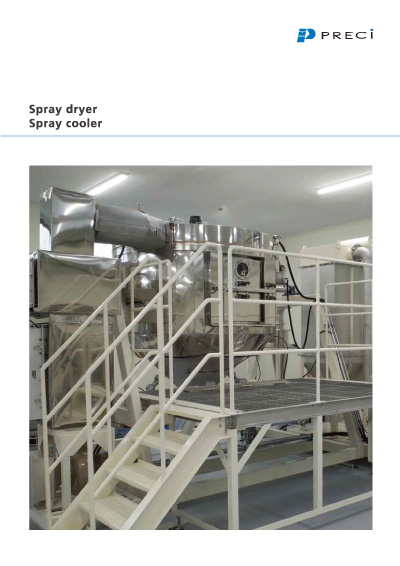

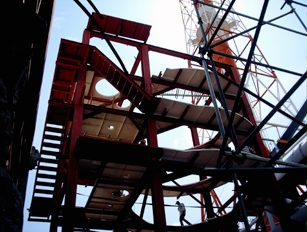

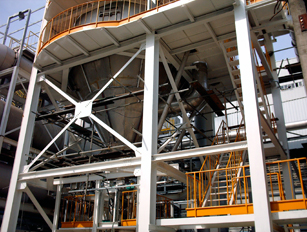

Facility examples

- Atomization mode:

- Pressure nozzle

- Drying chamber diameter:

- φ4800 mm

- Height:

- 18m

- Water evaporation capacity:

- 1200kg/h

- Atomization mode:

- Rotary atomizer

- Drying chamber diameter:

- φ5000mm

- Height:

- 13m

- Liquid material processing capacity:

- 350kg/h

- Atomization mode:

- Pressure nozzle

- Drying chamber diameter:

- φ4800mm

- Height:

- 18m

- Water evaporation capacity:

- 1200kg/h

- Atomization mode:

- Rotary atomizer

- Drying chamber diameter:

- φ6300mm

- Height:

- 19m

- Water evaporation capacity:

- 1000kg/h

- Atomization mode:

- Rotary atomizer

- Drying chamber diameter:

- φ3400mm

- Water evaporation capacity:

- 86kg/h

- Atomization mode:

- Rotary atomizer

- Drying chamber diameter:

- φ4000mm

- Water evaporation capacity:

- 100kg/h

- Atomization mode:

- Rotary atomizer

- Drying chamber diameter:

- φ5000mm

- Liquid material processing capacity:

- 500kg/h

Send an inquiry by contact form

PRECI takes your privacy seriously. All information you provide shall be held in strict accordance with our Privacy Policy.

* are required fields.