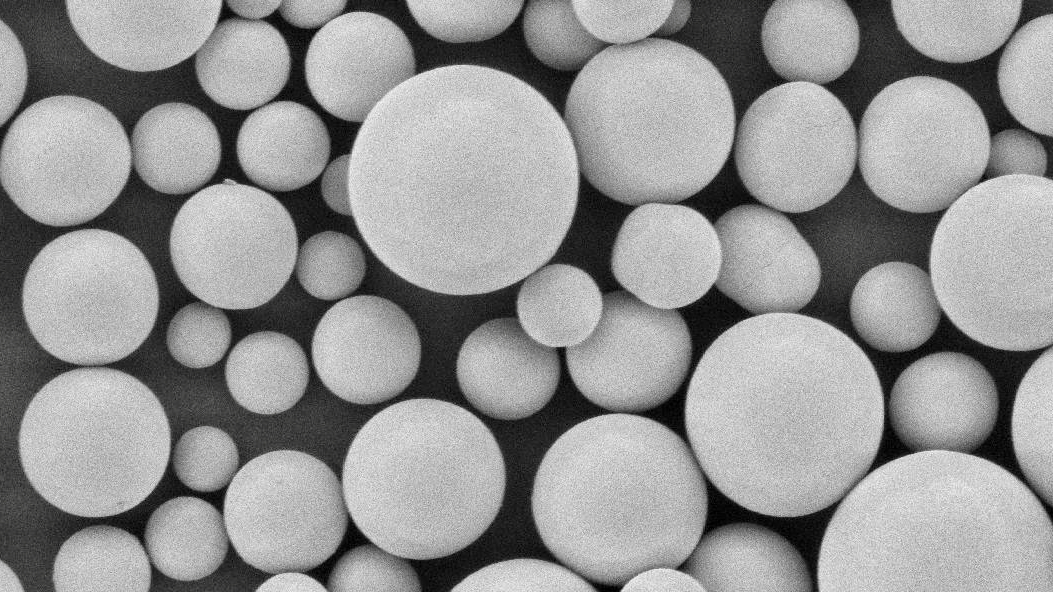

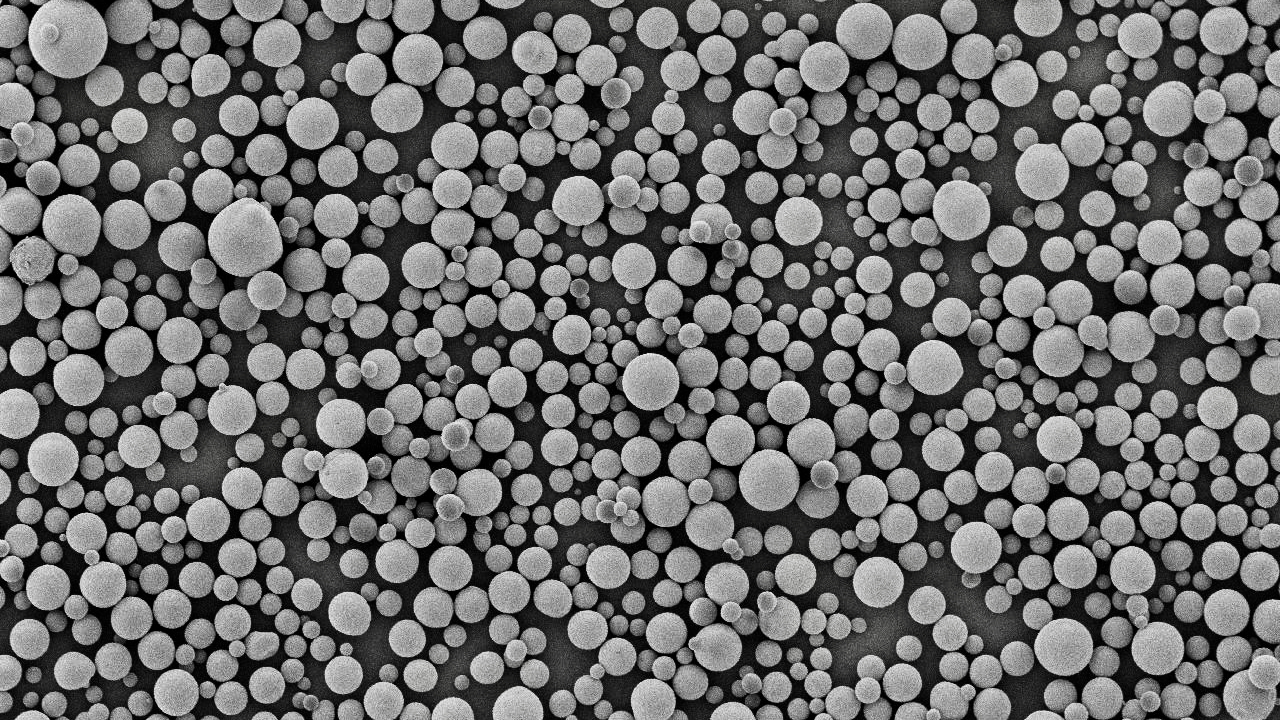

Nanoparticles are ultrafine particles whose diameter is measured in nanometers. One nanometer is equivalent to one billionth of a meter. Nanoparticles have a large surface area per unit volume, which facilitates intermolecular interactions and allows them to exhibit unique properties and behaviors compared to larger particles. Therefore, nanoparticles are used in a variety of applications, including drug delivery, cosmetics, and electronic materials, taking advantage of their unique properties.

Nanoparticles include the following materials:

Semiconductor nanoparticles, including quantum dots

Nanoparticles with optical properties useful for solar cells, electronics, biomarkers, bioimaging, etc.

Examples: CdS, CdSe, CdTe, ZnS, ZnO, Si nanoparticles

Metal nanoparticles

Metal nanoparticles used in catalysts, medicines, electronics, etc.

Examples: gold, silver, copper

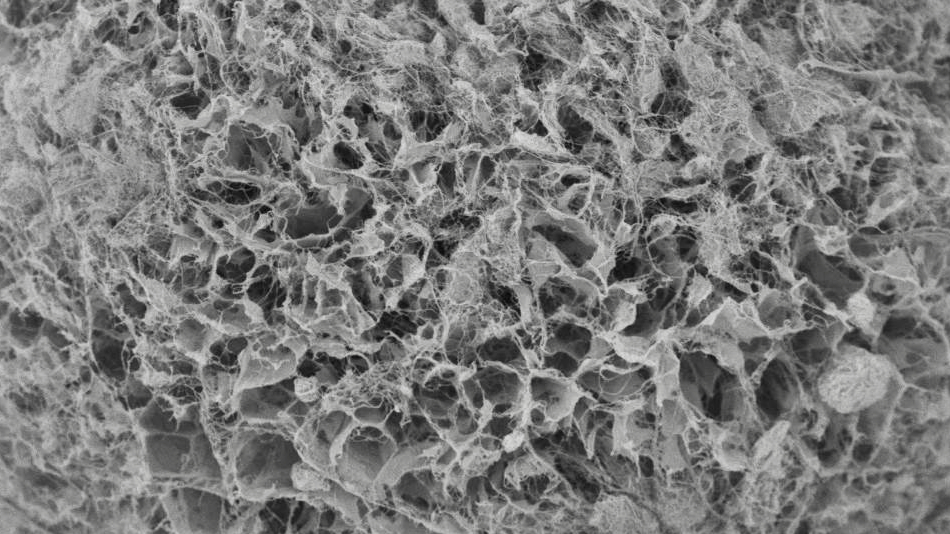

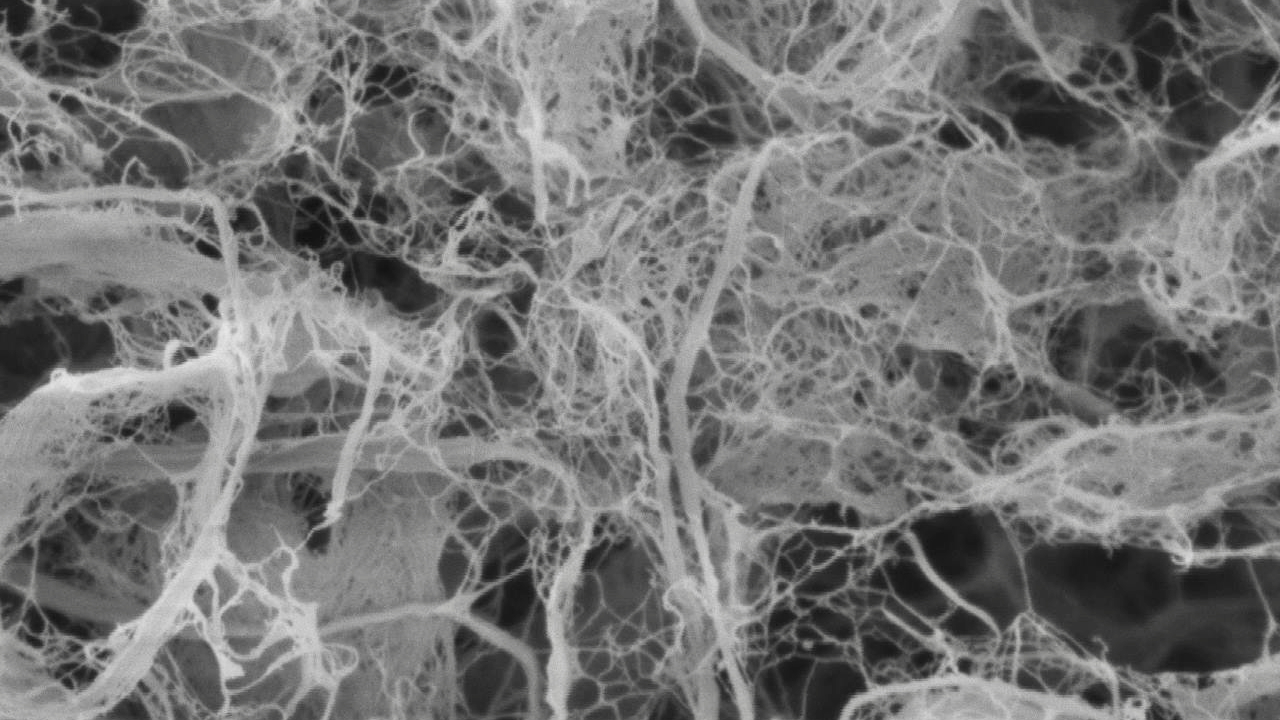

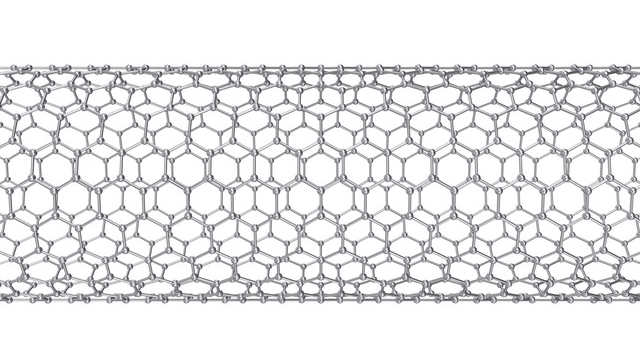

Nano-carbons

Nano-carbons used in cosmetics, composite materials, drug delivery, electronics, etc.

Examples: carbon nanotubes, graphene, fullerenes

Nano-polymers

Nano-polymers used in cosmetics, food encapsulation, drug delivery, etc.

Examples: polystyrene, polylactic acid

There are several processes for manufacturing nanoparticles, including:

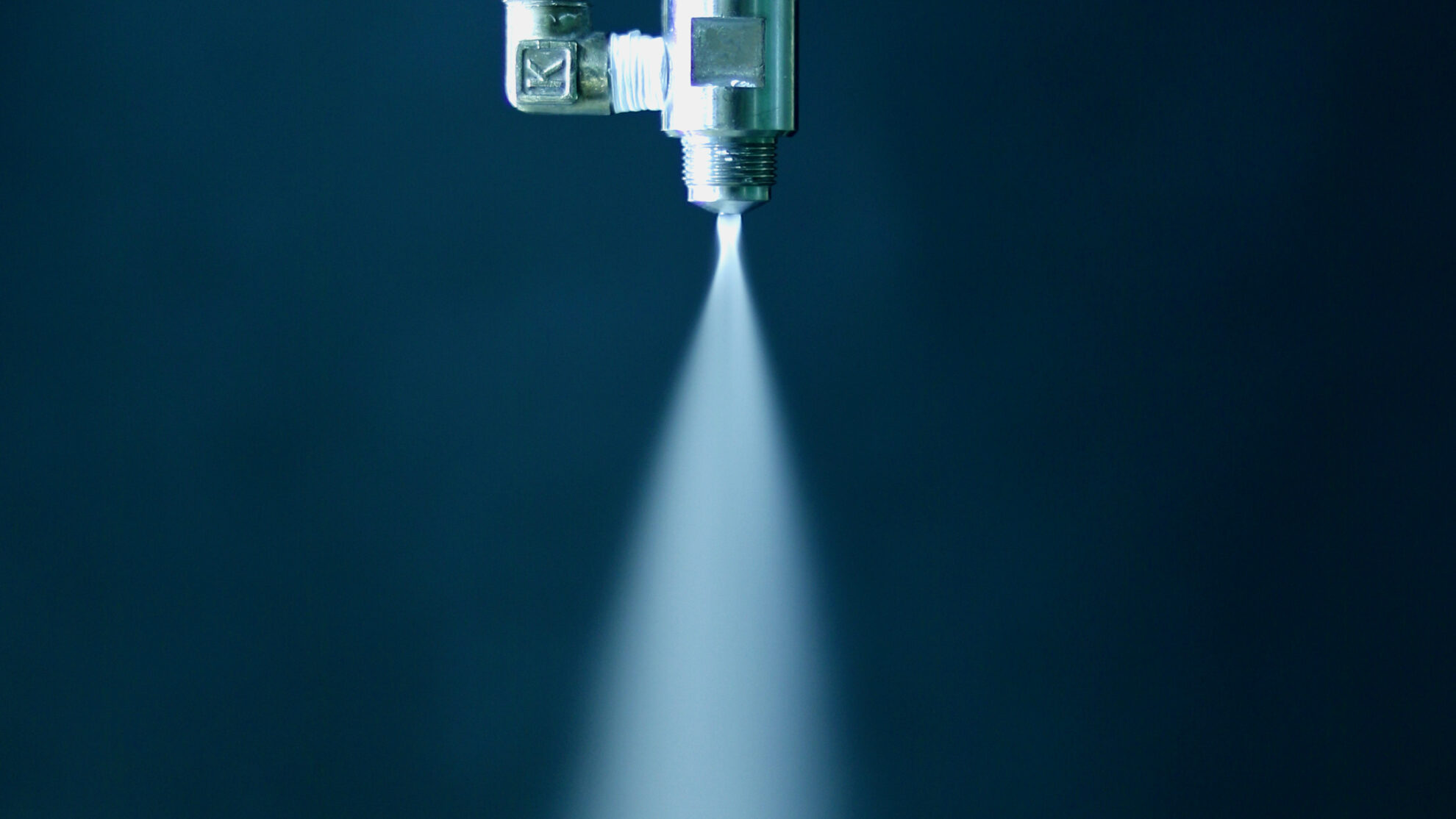

Salt-added spray pyrolysis

Metal salts are sprayed into a pyrolysis furnace, and the droplets evaporate to form particles. After pyrolysis, the salt is removed to produce nanoparticles.

Chemical vapor deposition (CVD)

Nanoparticles are formed by injecting precursors into a vaporization chamber and depositing them.

Arc discharge

Metal ions are generated by arc discharge, which deposits and forms nanoparticles.

Laser ablation

Metals or metal salts are irradiated with a laser to vaporize them, which then rapidly condense to form nanoparticles.

Sonochemical synthesis

Ultrasound is used to form nanoparticles of metals or metal salts.

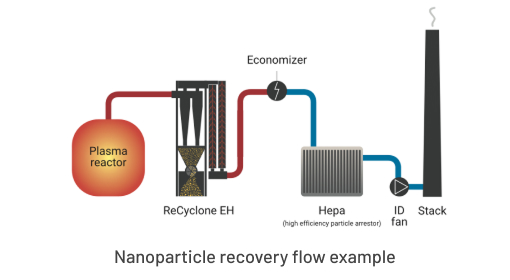

Nanoparticles present challenges when it comes to separating them from a gas. Nanoparticles are difficult to be captured using conventional cyclones and other mechanical separation processes due to extremely small sizes. Nanoparticles easily pass through the pores of baghouses. Furthermore, when using electrostatic precipitators, the nanoparticles can change and degrade during retention in the filters.

ACS product lineup includes ReCyclone EH with electrostatic recirculation. By directly capturing particles through electrostatic recirculation, particle degradation and aggregation can be avoided. ReCyclone EH has a proven track record of achieving a collection efficiency of over 95% for ZnO nanoparticles with a median diameter of approximately 1 μm and over 90% for silicon nanoparticles with a median diameter of 20 to 30 nm (Reference: NASA article, page 31).

Advanced Cyclone Systems (ACS) is a company exclusively dedicated to the development and commercialization of high-efficiency cyclone systems that incorporates the PACyc (Particle Agglomeration in Cyclones) model into design optimization simulations. In 2023, we concluded an exclusive distributorship agreement in Japan territory. In addition to our range of spray dryers, spray coolers and freeze granulators, we also offer high-efficiency cyclones for powder recovery and emission control fields. ACS has fulfilled over 400 successful installations in 37 countries.

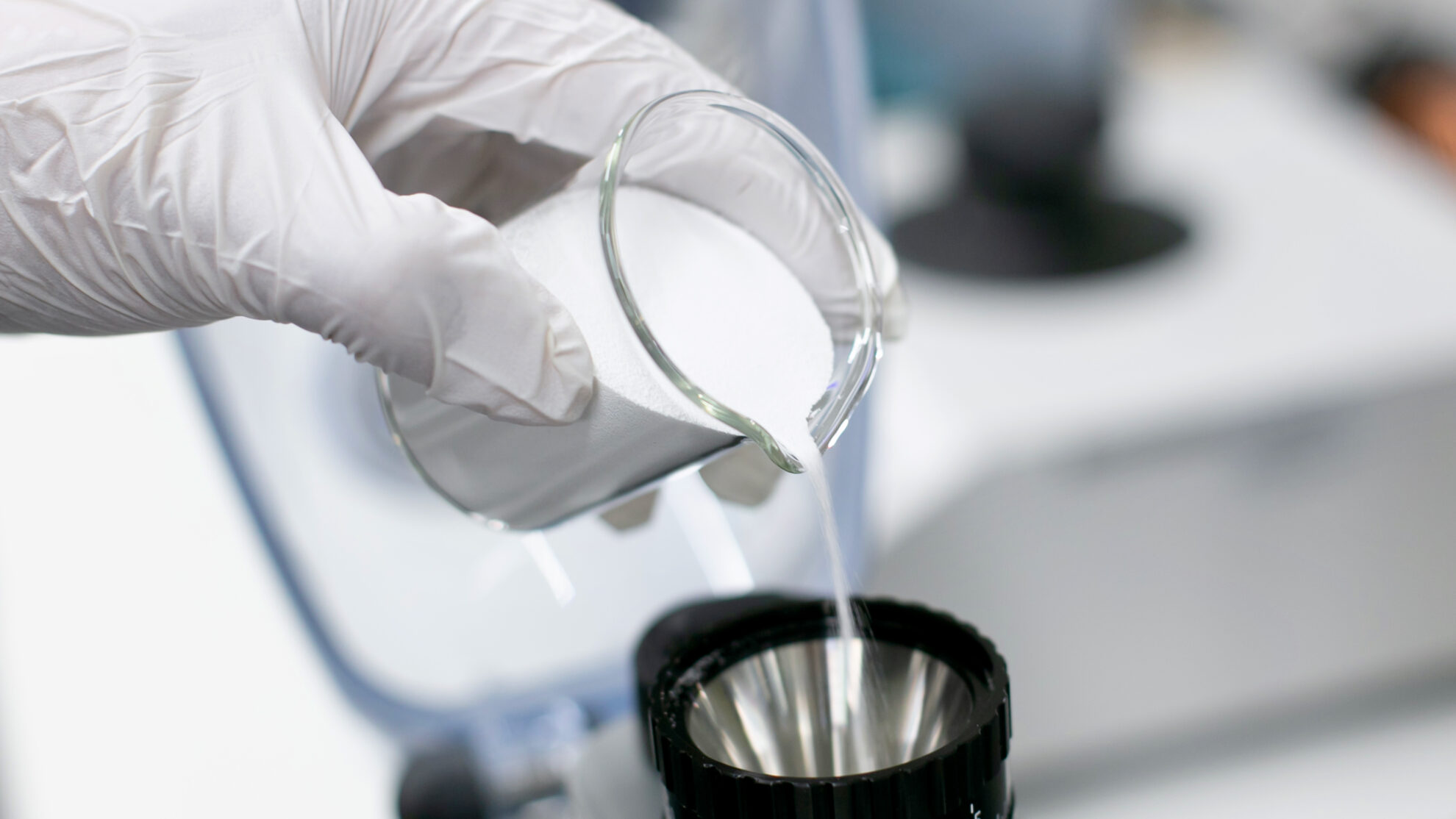

We handle spray dryers, spray coolers, and freeze granulators that use ACS cyclones. Drawing on our accumulated experience and track record, we design optimal processes that meet the required quality. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.