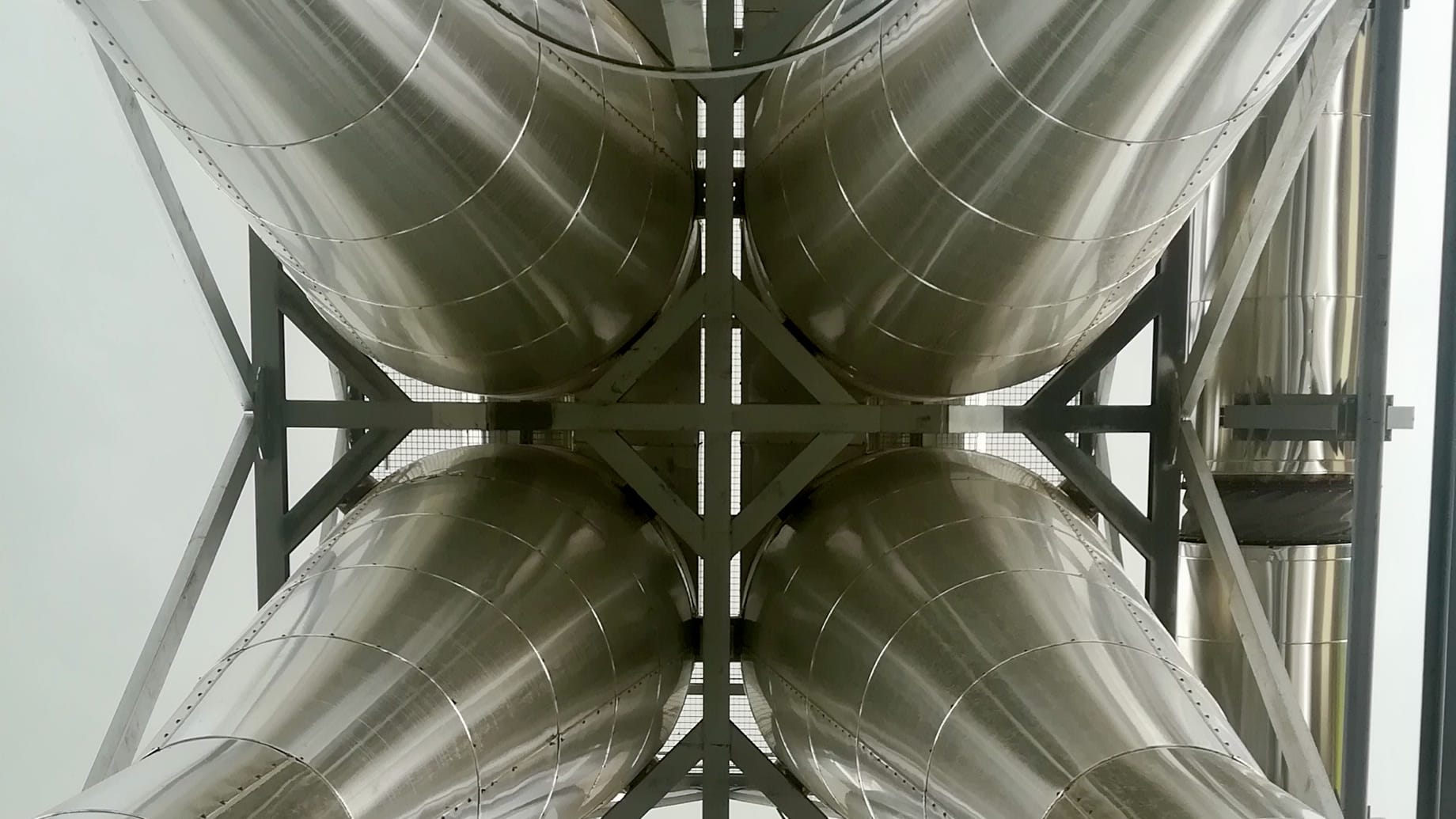

Advanced Cyclone Systems (ACS) is a company exclusively dedicated to the development and commercialization of high-efficiency cyclone systems that incorporates the PACyc (Particle Agglomeration in Cyclones) model into design optimization simulations. In 2023, we concluded an exclusive distributorship agreement in Japan territory. In addition to our range of spray dryers, spray coolers and freeze granulators, we also offer high-efficiency cyclones for powder recovery and emission control fields. ACS has fulfilled over 400 successful installations in 37 countries.

Pharmaceuticals

Particle separation and recovery is a necessary process for drying, blending, milling, atomization, and tablet compression processes of a wide variety of active pharmaceutical ingredients (APIs) and powder medicines.

Spray drying

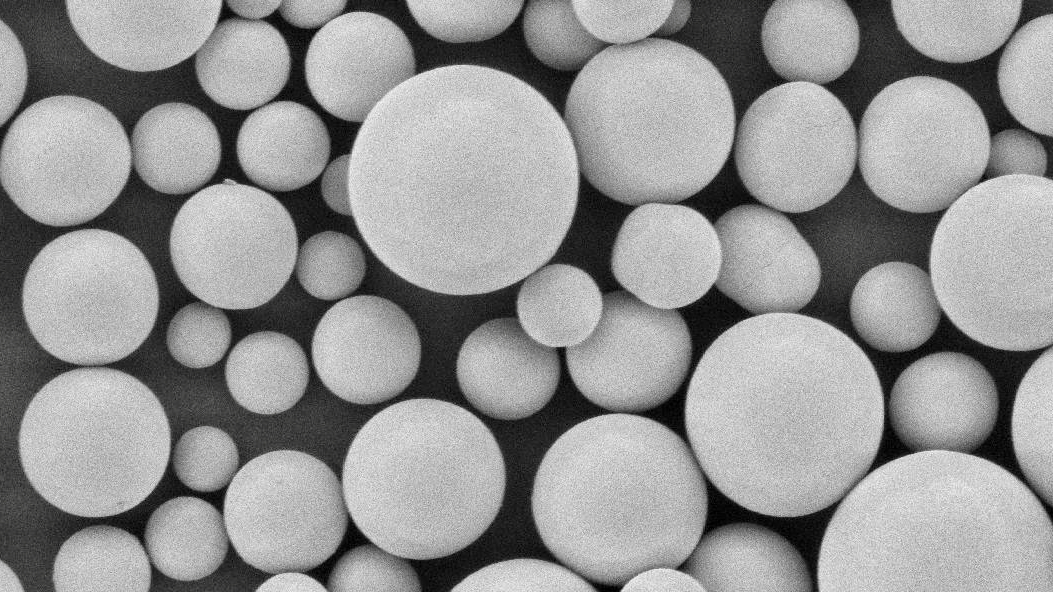

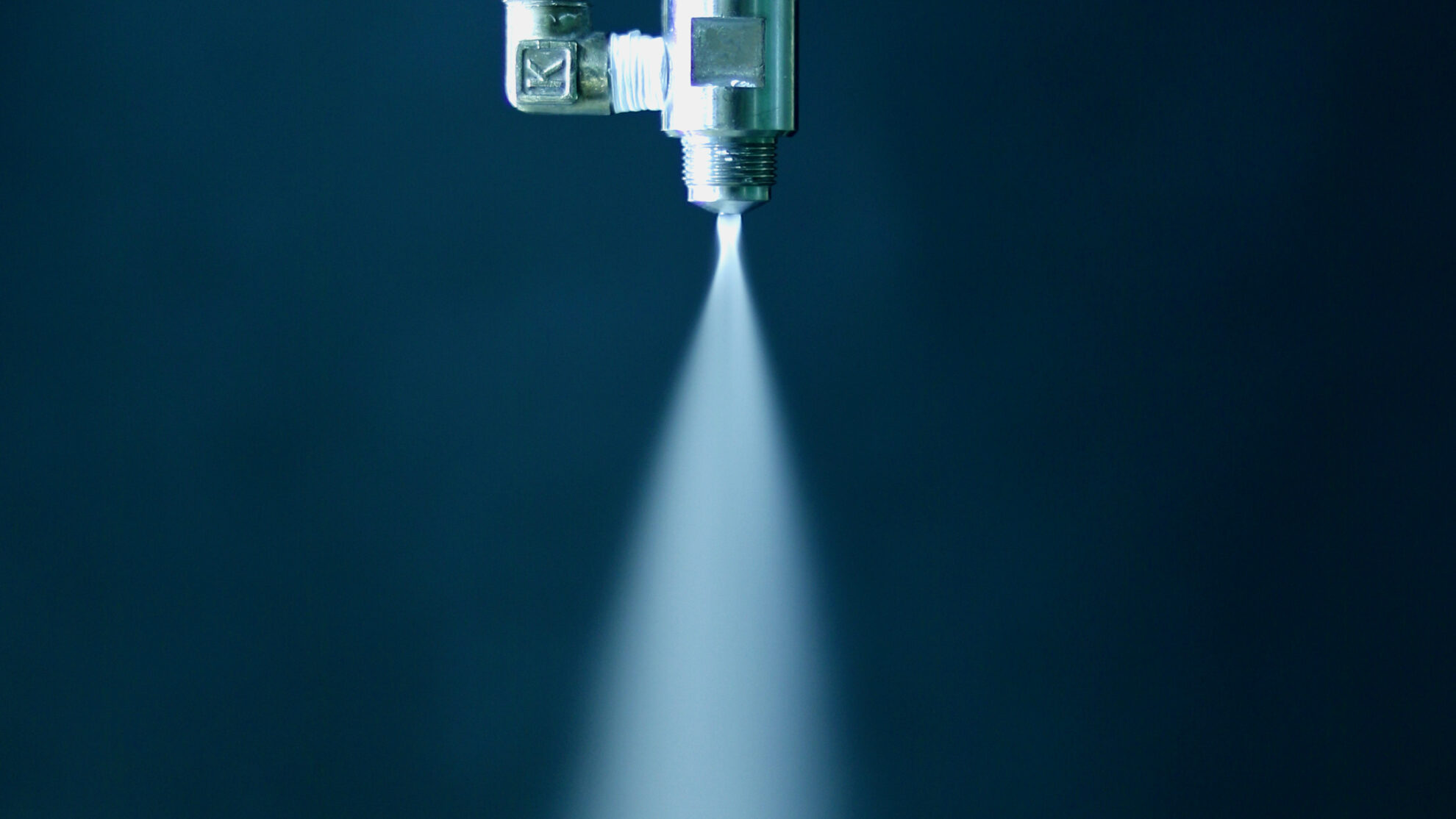

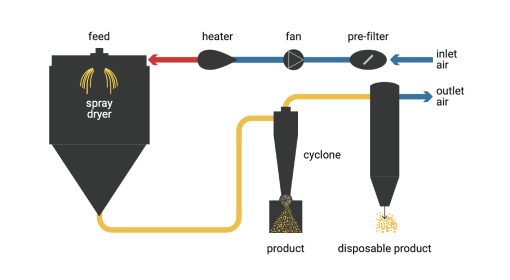

Efficient powder recovery after spray drying can be very challenging, especially for expensive products or small particle sizes. Spray dryers typically have a high-efficiency cyclone and baghouse after the drying chamber to prevent product from escaping into the exhaust gas.

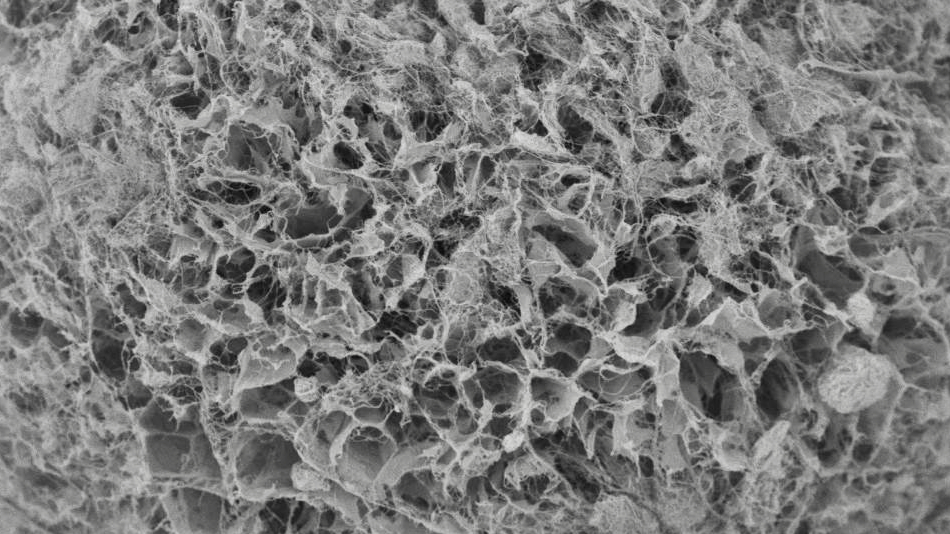

Cyclones offer excellent hygienic properties. Unlike baghouses, cyclones avoid product contamination through filter fibers, making them a must-have spray drying layouts in pharmaceuticals. Cyclones are easy, fast and effective in clean-in-place, allowing for the rapid and effective separation of different powder batches without cross-contamination of products. Therefore, a baghouse placed downstream of the cyclone only serves to protect the HEPA filter, and the collected powder may be discarded. Product losses caused by using an inefficient cyclone result in increased costs. Even if the product is inexpensive, it is considered to be environmentally and socially irresponsible, so improving product collection efficiency is also a waste management issue that needs to be addressed. It is important to use cyclones that are easy and quick to clean, not only to maximize powder yield but also to enable rapid product changeover.

Featuring a range of GMP-compliant, high-efficiency cyclones, ACS solutions dramatically reduce losses, even with the finest products. Every model is individually optimized to meet the requirements of the installation. Smaller units use only a tri-clamp and can be disassembled for quick and hassle-free cleaning.

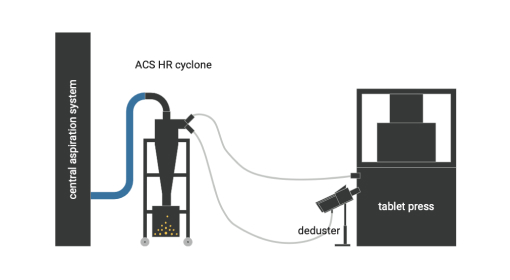

Tableting and encapsulation

Tablet pressing and encapsulation processes may pose a risk to workers due to dust generation and potential cross-contamination of products between subsequent batches. Therefore, these processes are connected to a local exhaust ventilation system (LEV) equipped with cartridge filters, followed by HEPA filters. ACS cyclones offer best practice waste powder management by providing highly efficient recovery of fine powders, which can be reintroduced into the process, and improving product yield.

ACS offers a wide range of GMP-compliant cyclones for tableting and encapsulation. Cyclones can be applied both for waste powder collection and powder recovery, and are much more efficient than other common cyclones. The cyclone unit includes a catch pot with sight glass and a base on wheels, and can be disassembled using only a tri-clamp for quick and hassle-free cleaning.

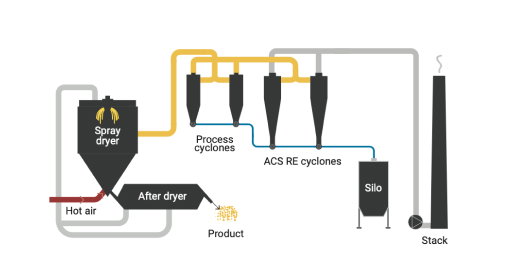

Foods

There is a wide variety of needs to separate powders from a gas in many industries, from dairy and chocolate to beverages, starch and yeast. Processes requiring product separation include drying (e.g. spray dryers or flash dryers), grinding and mixing. Efficient recovery of food powders can be challenging, especially when the particles are fine. This challenge is particularly seen in spray drying, a process used to dry high-value powder products such as demineralized whey and whey protein concentrate. Spray drying processes typically include a process cyclone and a final dedusting system (such as a baghouse, wet scrubber, or WESP).

In spray drying, process cyclones separate and collect dry powders from gas that has passed through the drying chamber. The portion of the fines that flows into the final removal system is considered a loss because it is waste (WESP and wet scrubber) or not considered a first-grade product (baghouse). The reason why it is not considered as first-grade products is due to the risk of contamination from filter fibers as well as product cross-contamination. The preferred method for highly efficient recovery of expensive powder products is to use cyclones, which capture powders directly and hygienically, not only for initial product recovery but also for final dust removal. Unlike baghouses and wet scrubbers, cyclones can avoid filter contamination and product cross-contamination. For fine powders with a volume median diameter (MVD) below 5 μm, losses due to low cyclone collection efficiency can be 25% or more. Even if the product is inexpensive, it is considered environmentally and socially irresponsible, so improving product collection efficiency is also a waste management issue. The advantages, disadvantages, investment and operational costs of final dedusting options are as follows:

Traditional cyclones and multi-cyclones

Problems

Low efficiency

Advantages

Low cost and easy cleaning

Quick product changeover

Disadvantages

Low particulate capture efficiency, preventing compliance with emission limits

Bag and ceramic filters

Problems

Operation and maintenance costs

Advantages

High efficiency (>99.9%), enabling compliance with a wide range of emission limits

Disadvantages

Temperature-sensitive

CIP-compatible units are expensive and require high maintenance costs

Cross-contamination of fibers and products can lead to sub-optimal product quality

Wet venturi scrubbers and WESPs

Problems

Secondary contamination

Advantages

Suitable for a variety of operating conditions

Disadvantages

Product cannot be recovered

Requires wastewater treatment facility

The separation and recovery of powder products in the first stage of the manufacturing process requires the process cyclone to be as efficient as possible to capture first-class products. High-efficiency cyclones can also be used in final-stage dust removal systems to recover fine powders. ACS offers high-efficiency process cyclones that maximize yield. Depending on the required emission limits and particle size, ACS cyclones can be an alternative solution to other dust removal systems, maximizing the yield of the entire production line.

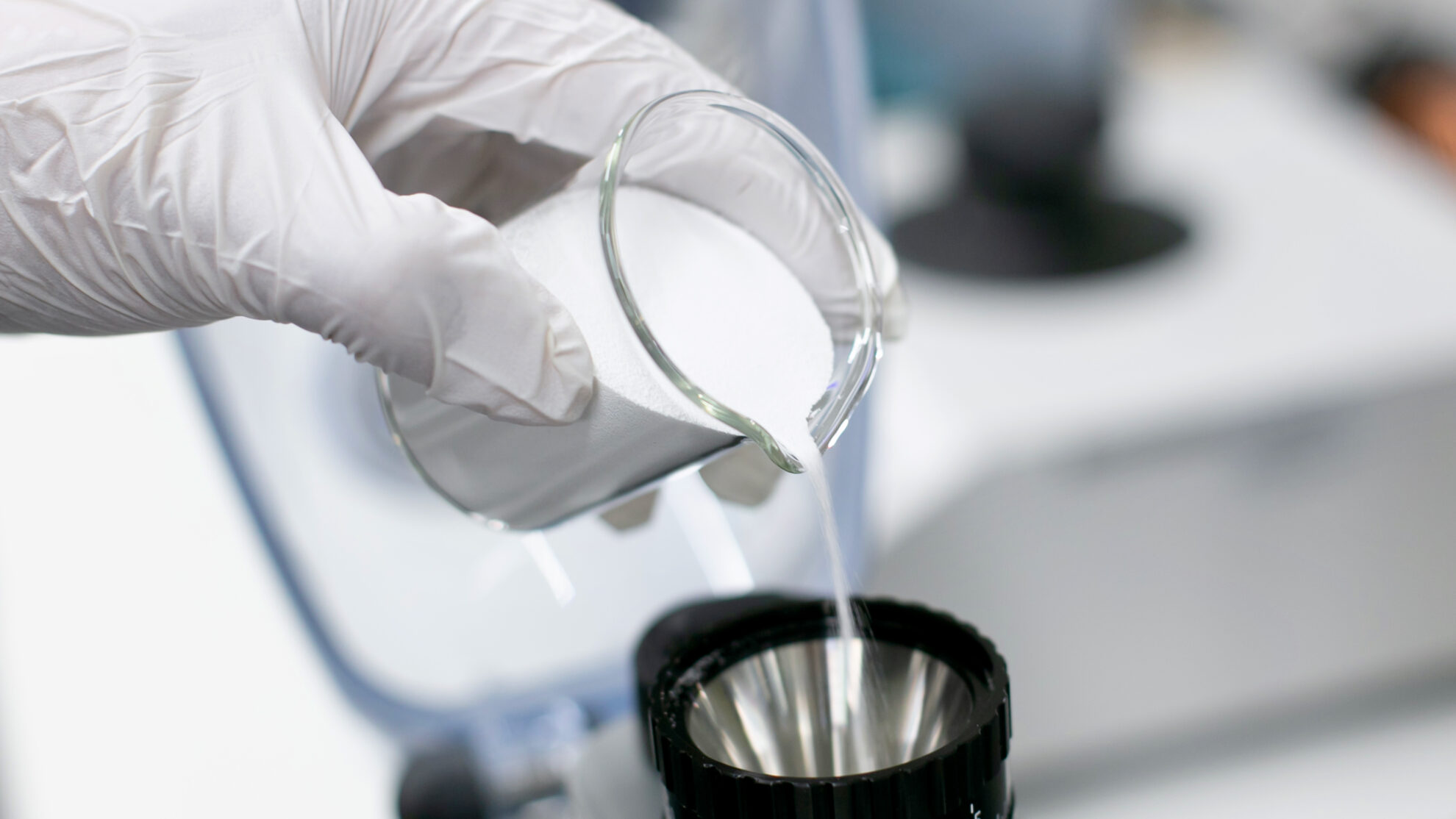

We handle spray dryers, spray coolers, and freeze granulators that use ACS cyclones. Drawing on our accumulated experience and track record, we design optimal processes that meet the required quality. In addition, we not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.