Index

Physical cleaning methods in precision cleaning systems are generally classified as follows (In actual cleaning processes, multiple cleaning methods may be used in combination rather than using a single method.) :

Ultrasonic cleaning

About ultrasound

Ultrasound is a sound wave that cannot be heard by the human ear, and is defined as “a sound with a frequency of 20 kHz or more per second that cannot be sensed by the ear as a steady sound.” High-frequency elastic vibration waves cannot be heard by humans, but their properties are utilized in a variety of fields. Ultrasound is mainly used for power purposes and information purposes. Below are some commonly known examples of ultrasound uses.

Power applications

Cleaning, processing (cutting, grinding, polishing, welding, joining), nozzle spraying, motors, emulsification, dispersion and coagulation for food applications, humidification, medical treatment

Information applications

Anemometers, current meters, distance meters, thickness gauges, communications, non-destructive testing, sonar, metal detection, destructive sound detection, leak detection, medical testing

About ultrasonic cleaning

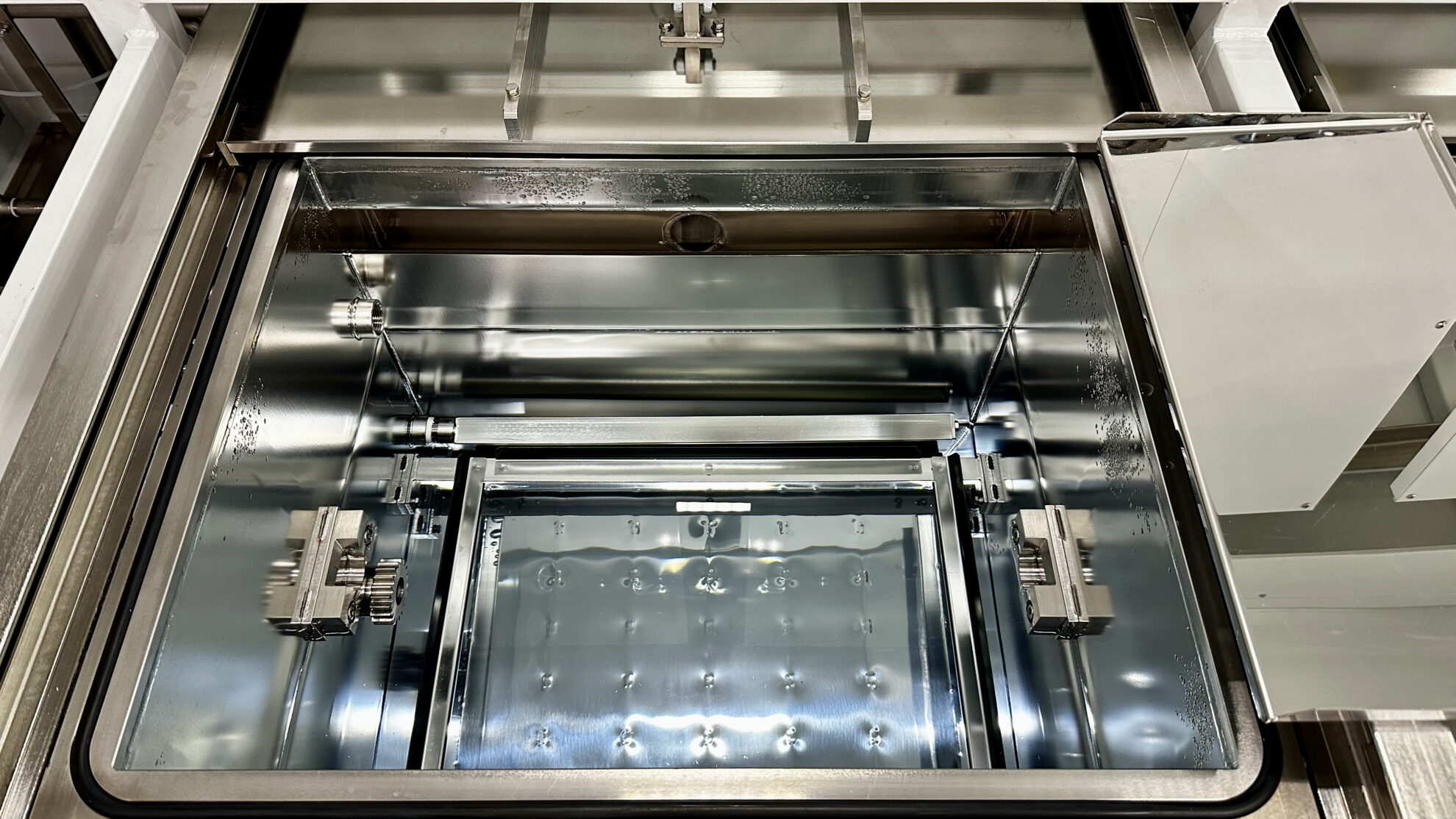

Ultrasonic cleaning is a cleaning method that uses ultrasonic vibrations to remove dirt and other contaminants from immersed objects. Liquid (water or cleaning chemical) is placed in a cleaning tank equipped with an ultrasonic vibrator that emits ultrasonic waves, and the objects are then immersed in the liquid. The vibrations produced by the ultrasonic vibrator are generated electrically by a separately installed ultrasonic oscillator. The operating frequency for ultrasonic cleaning is generally between 15 kHz and 3 MHz, and is determined based on the material and strength of the object being cleaned and the type of dirt. Ultrasonic cleaning using low frequencies (up to approx. 100 kHz) increases cleaning power but also causes greater damage to the object being cleaned. At medium frequencies (up to approx. 500 kHz), the cavitation effect is weakened, but the vibration acceleration effect increases, allowing for gentler cleaning.

Ultrasonic cleaning principles

Ultrasonic cleaning achieves its effectiveness through the synergistic effect of the physical action of ultrasound and the chemical and physical effects of cleaning agents and solvents.

Physical effects

Cavitation, vibration acceleration, and impact effects due to linear flow

Chemical and physicochemical actions

Surface activity (emulsification, dispersion), builder effect, chemical reactions (saponification, oxidation, reduction), and dissolution by detergents

Cavitation

Ultrasound generates and bursts tiny bubbles in liquids (cavitation). Ultrasound creates alternating positive and negative pressure in the liquid. When the pressure drops below the saturated vapor pressure, the liquid foams, and the foamed bubbles collapse when exposed to high pressure. When the bubbles collapse, they collide, creating pressure waves that create shock waves. This shock can be used to remove and remove dirt and contaminants.

Vibration acceleration

Ultrasonic waves generated in liquid vibrate the liquid molecules, causing accelerated motion. This accelerated motion exerts a physical effect on the object being cleaned, peeling and removing dirt and particles. Vibration acceleration increases in proportion to the square of the frequency. Therefore, the higher the frequency, the greater the cleaning effect. Cleaning using high frequencies (up to 1 MHz) results in gentler cleaning with less damage to the object being cleaned.

Linear flow

At high frequencies, ultrasonic energy is increased, generating linear flow in the liquid. Linear flow generates convection within the liquid, resulting in a dispersion effect. This is effective for rinsing precision parts that require a high level of cleanliness, as well as for dispersing fine particles.

Ultrasonic cleaning may also be combined with other physical processes, such as:

- Oscillation or rotation cleaning using a rotating cleaning basket

- Degassing to enhance cleaning power and stabilize the liquid flow

- Vacuum cleaning that allows liquid to penetrate into fine spaces within the object

Shower, spray, jet cleaning

Shower, spray and jet cleaning are cleaning methods that spray liquid from a nozzle onto the object being cleaned to remove adhering dirt and contaminants. They are classified by name according to the spray pressure. Generally, the pressure of shower cleaning is up to 250 kPa, spray cleaning up to 2 MPa, and jet cleaning above 2 MPa. Shower and spray cleaning are relatively gentle cleaning methods and are mainly used in rinsing and finishing processes. On the other hand, jet cleaning sprays liquid at high pressure, so it is used when the dirt adhering to the object is stubborn and strong. Cleaning performance can be changed by adjusting the type of nozzle and spray pressure. The liquid is sprayed from the air, and acts evenly on the object. It is mainly built as an inline system integrated with a conveyor system.

Immersion, submerged jet, bubbling cleaning

Immersion cleaning is a cleaning method in which the object to be cleaned is immersed in a liquid. The object is immersed in a cleaning tank filled with cleaning chemical to remove dirt and contaminants. It is used to clean delicate products such as IC chips that are difficult to treat with physical action. The cleaning performance of immersion cleaning is determined by the concentration of the cleaning chemical, the temperature of the liquid, and the immersion time. There is also immersion oscillation cleaning, in which the object is oscillated in the liquid.

In submerged jet cleaning, the object to be cleaned is immersed in a liquid and a liquid flow is generated using a pump. Because the physical action is weak, the cleaning effect is low, but the damage to the object is also small. Compared to shower cleaning, which sprays liquid into the air, it creates less foam, so it is mainly used as a cleaning method that uses surfactants.

Bubbling cleaning creates bubbles in the liquid, and as the bubbles rise they gently come into contact with the object being cleaned. The interface between the gas and liquid becomes a solid substrate, and as this interface comes into contact with the object being cleaned, particles are removed. It has a low physical effect, so it is used to clean products that are sensitive to damage.

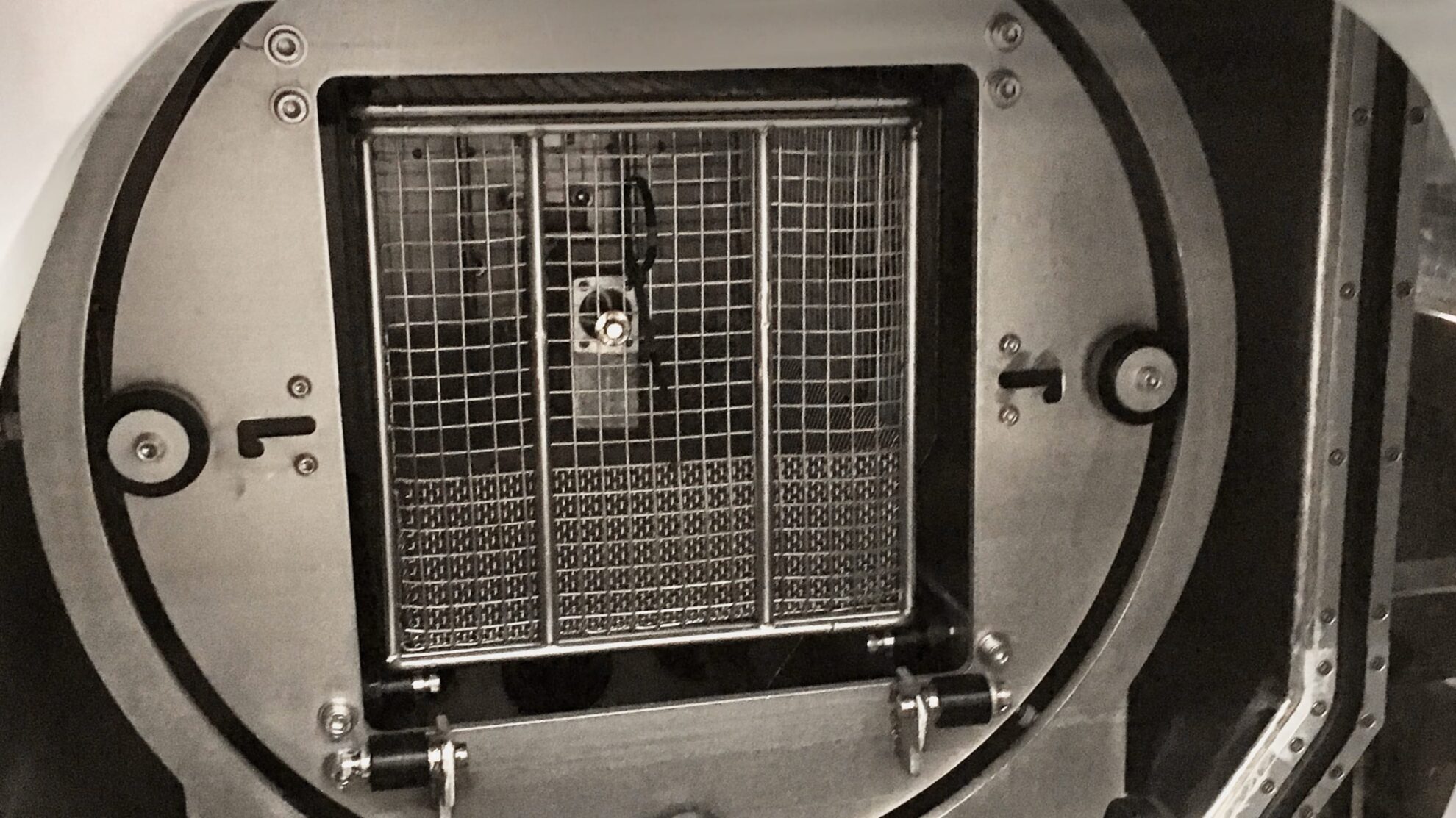

Barrel, oscillation cleaning

The objects to be cleaned are placed in a rotating cleaning basket, which is then swung or rotated in the liquid to clean them. By using ultrasonic cleaning in combination, more uniform cleaning can be achieved. This method is used for degreasing industrial parts, etc. In the finishing cleaning process, steam may be used instead of liquid. As the liquid has low penetration power, this method is not suitable for items with complex shapes or blind holes. Also, as the items to be cleaned are constantly in contact with each other, it is not suitable for parts with shapes that are easily damaged.

Degassing cleaning

Degassing cleaning is mainly used in conjunction with ultrasonic cleaning. Ultrasonic cleaning may not be effective because the dissolved gas in the liquid reduces the effectiveness of the ultrasound. In such cases, it is possible to improve cleaning performance by degassing the liquid to reduce the amount of dissolved gas. The saturated dissolved gas level is controlled by monitoring the dissolved oxygen concentration (DO value). If the saturated dissolved gas level is too low, it will inhibit the cavitation effect, so it must be adjusted appropriately. Degassing also reduces the generation of bubbles and stabilizes the liquid flow.

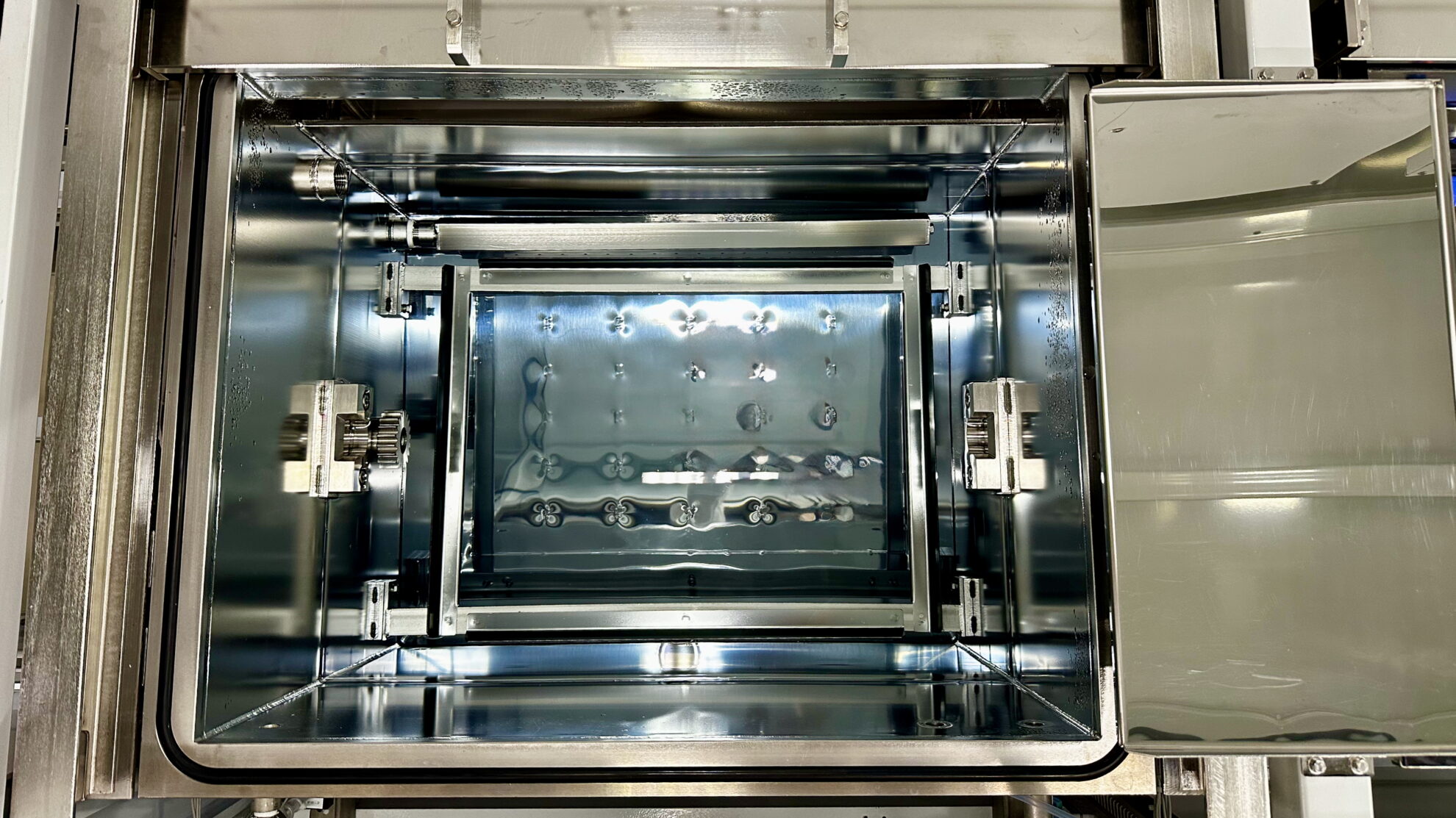

Vacuum cleaning

Vacuum cleaning is primarily used in conjunction with ultrasonic cleaning and is suitable for cleaning parts with deep blind holes. By drawing a vacuum inside the cleaning tank, air clogs such as blind holes are removed. After that, the vacuum is released and the liquid enters the holes. By allowing the cleaning liquid to penetrate into the minute spaces in the object being cleaned, it is possible to eliminate uncleaned areas. In addition, like degassing cleaning, it also degasses dissolved gases contained in the liquid, which also has the effect of enhancing the cavitation effect of the ultrasonic waves.

Vapor cleaning

Vapor cleaning involves heating and boiling a solvent to generate vapor, which is then brought into contact with the object to be cleaned. The evaporated vapor condenses when it comes into contact with the object and flows off the surface. Dirt and contaminants are separated and dissolved in the solvent, and the dirt and solvent are separated in a distillation regenerator. The distilled and regenerated solvent can be reused. Vapor cleaning is mainly used for finish cleaning and as a final rinse before drying. Immersion cleaning and ultrasonic cleaning are used for the previous stage of vapor cleaning.

Summary

- Ultrasonic cleaning removes dirt and contaminants through the impact action of cavitation, vibration acceleration, and linear flow.

- Shower, spray, and jet cleaning remove dirt and contaminants by spraying liquid from a nozzle.

- Immersion cleaning involves immersing the item to be cleaned in liquid. Immersion oscillation cleaning is also available.

- Submerged jet cleaning removes dirt and contaminants using a liquid flow. Because cleaning is done in liquid, there is less foaming.

- Bubbling cleaning removes dirt and contaminants through gentle cleaning using bubbles.

- Oscillation/rotating cleaning involves cleaning by oscillating or rotating the object in the liquid. Ultrasonic cleaning may also be used in combination.

- Degassing cleaning is mainly used in combination with ultrasonic cleaning, and increases cleaning power by reducing the amount of dissolved gas.

- Vacuum cleaning is mainly used in combination with ultrasonic cleaning, and is suitable for cleaning parts with deep blind holes.

- Vapor cleaning involves bringing vapor into contact with the object to be cleaned. It is mainly used for finish cleaning.

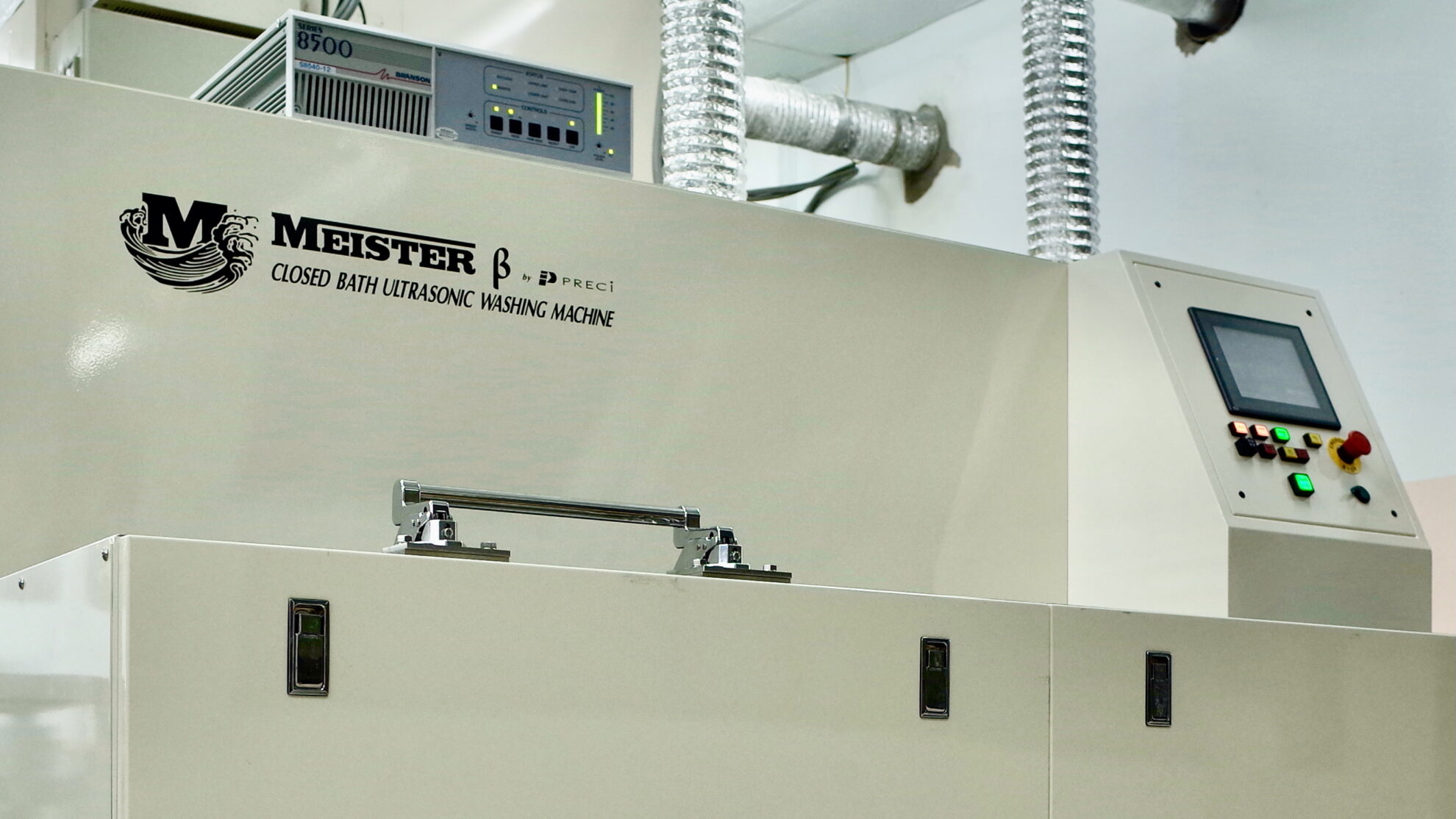

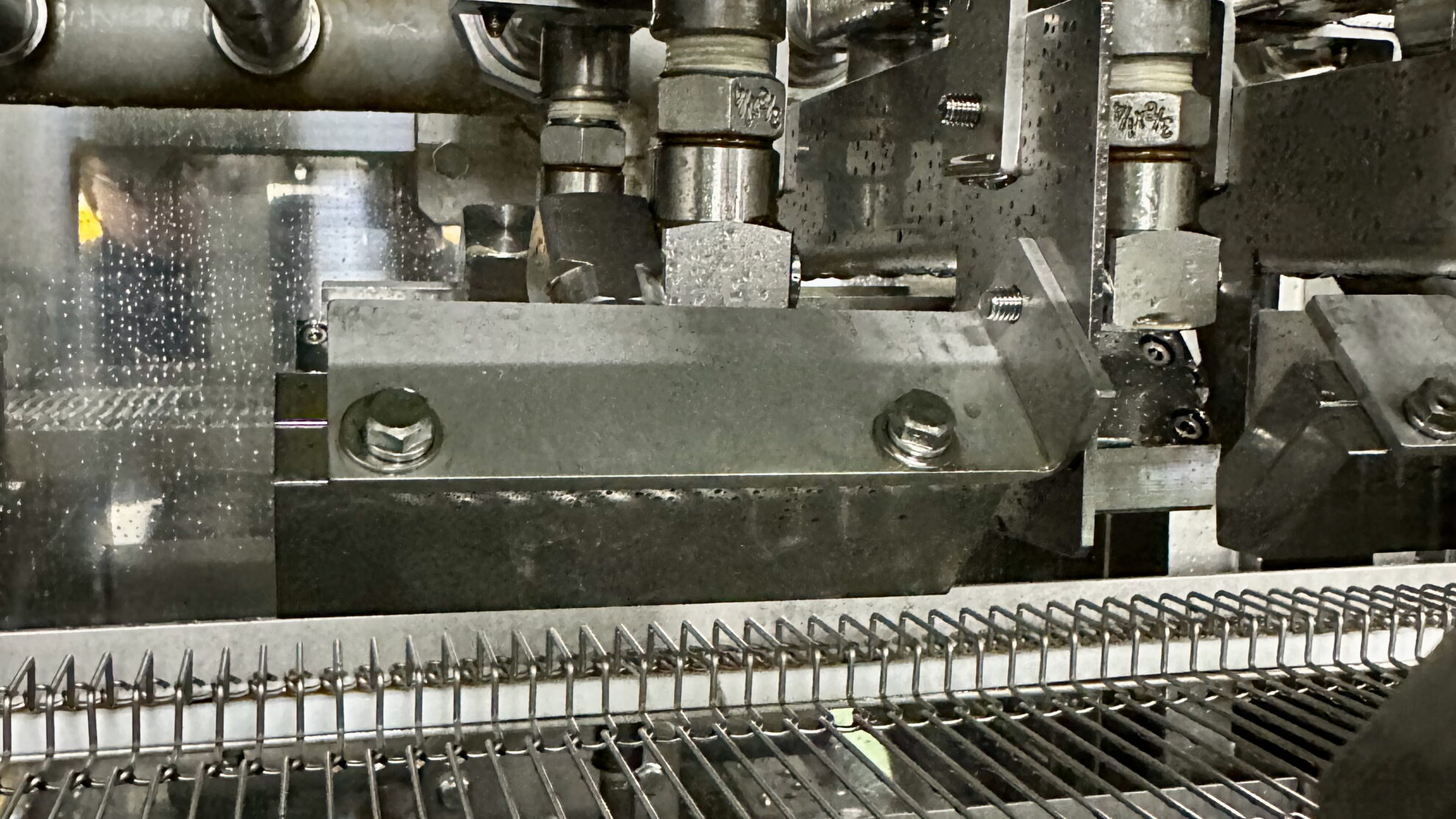

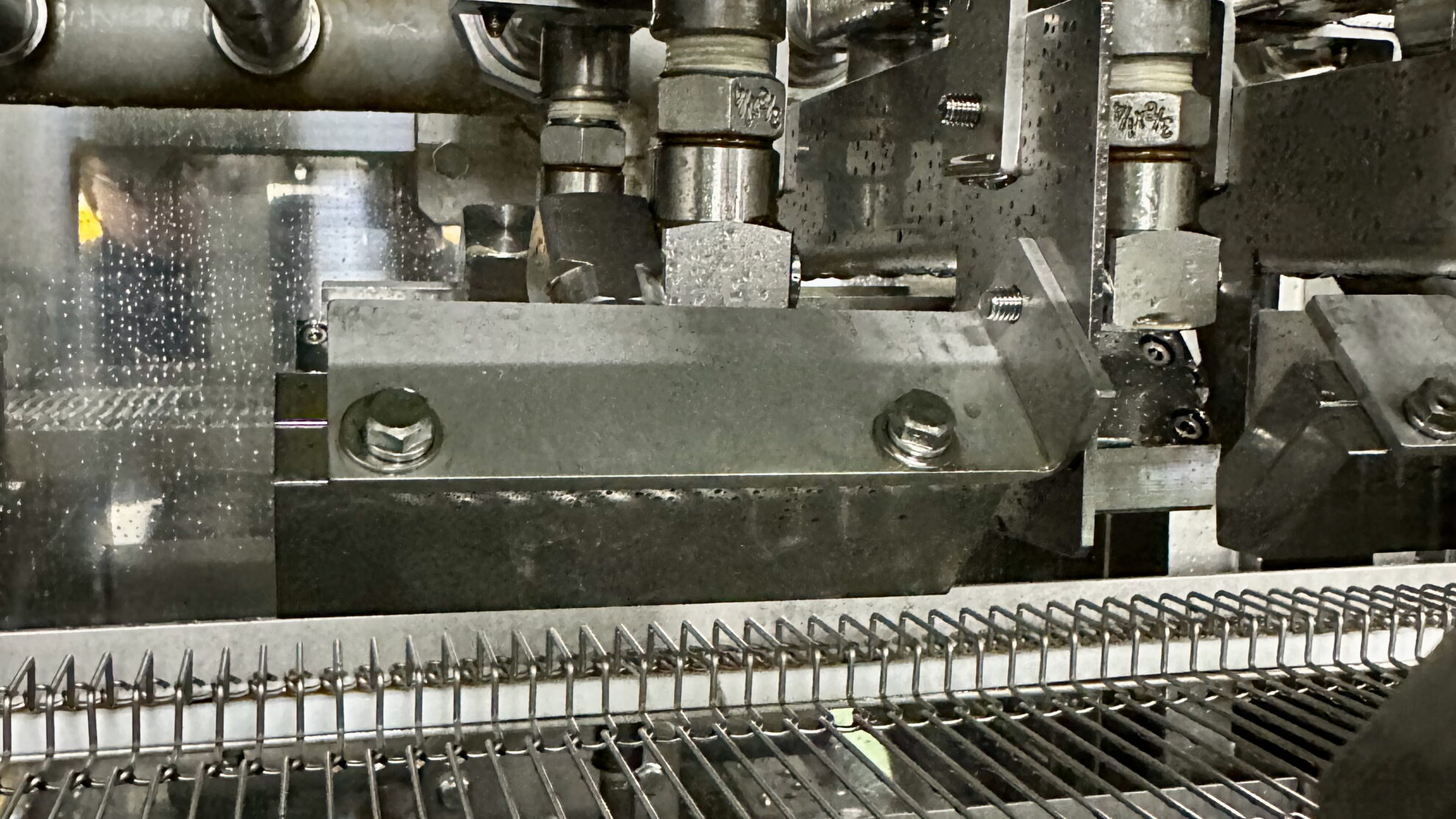

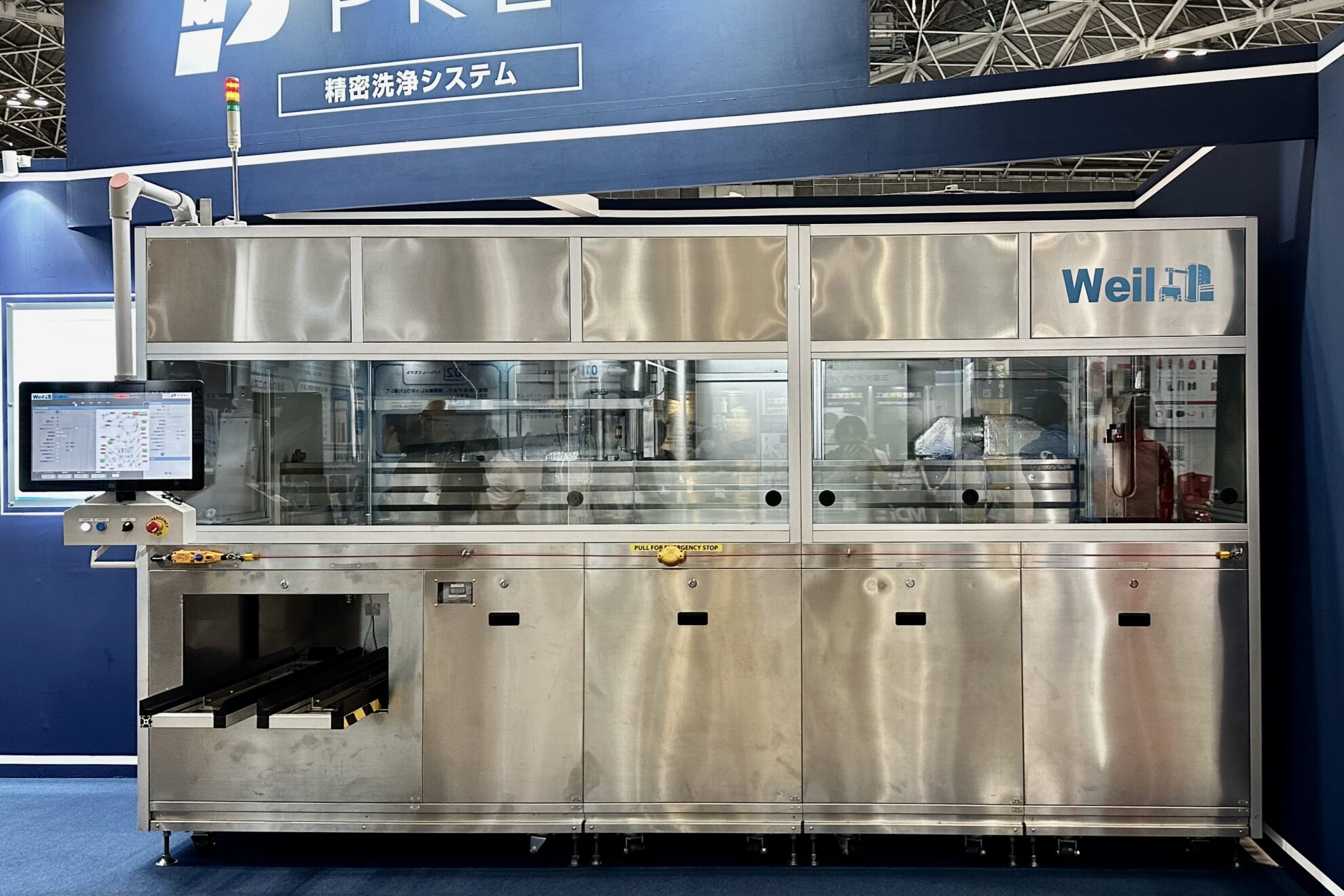

We provide precision cleaning processes that combine high cleaning performance with environmental friendliness. We handle a wide range of cleaning methods, including ultrasonic, spray, shower, submerged jet, barrel, degassing, vacuum, and combinations of these methods. We design processes that minimize the consumption of cleaning chemicals and operating costs, such as electricity consumption. Ancillary equipment includes dehydration, vacuum drying, vapor drying, concentration, filtration, distillation regeneration, pure water production and regeneration, etc., depending on the applications. Conveyor systems can be selected from among net conveyor, basket, hoop, etc. Cleaning processes can be controlled from manual to full automation. It is also possible to implement the minimum level of automation according to the budget constraints. Recipe and lot management, communication between pre- and post-processes, and communication with the user’s central control system can also be supported.

Our cleaning test center (CTC) offers cleaning trials using actual workpieces, as well as analysis and measurement services. Through partnerships with a wide variety of cleaning chemical suppliers, we rationally determine and propose the most cost-effective chemicals in terms of performance.