Index

Cleaning liquids with chemical and physical properties are selected depending on the type of dirt and contaminants, and cleaning methods. In actual cleaning processes, multiple cleaning chemicals may be used in combination rather than a single one.

Types of dirt and contaminants

Dirt can be broadly divided into three types: water-soluble organic dirt, oil-based dirt, and solid contaminants. In reality, dirt and contaminants can be a combination of these types.

Water-soluble organic dirt

Dirt made from water-soluble organic components include relatively soluble substances such as sugars, and less soluble dirts that can be dissolved in weak acid or alkaline solutions.

Oil-based dirt

Oil-based dirts are substances that are virtually insoluble in water and must be dissolved using organic solvents. The solvent to be selected varys depending on the components, their polarity, etc.

Solid contaminants

Solid contaminants occurs when particles such as dust or fine particles adhere to the surface. Inorganic solids, such as fine particles, can be either hydrophilic or hydrophobic depending on the surface condition of the solids.

Types of cleaning method

Cleaning methods are broadly divided into stripping and dissolution. Cleaning chemicals are designed with ingredients that suit their purpose and application. It is important to consider not only the unit price of the chemical, but also consumption efficiency and whether or not it can be recycled or not. Generally, water-based cleaning chemicals are inexpensive, while semi-aqueous and non-aqueous cleaning chemicals tend to be more expensive.

Strip cleaning

Strip cleaning is a process that removes dirt and contaminants adhering to the object being cleaned. It is mainly used in aqueous cleaning processes that use surfactants and alkaline chemicals.

Surfactants

Surfactants have an amphiphilic molecular structure with both hydrophilic and lipophilic groups, and act at the interface among the liquid, the solid dirt, and the object being cleaned. The main properties of surfactants are the reduction of interfacial tension and the formation of micelles. Surfactants first penetrate into the dirt interface and then separate it. Next, the emulsifying and dispersing action keeps the dirt separated in the liquid, preventing it from re-adhering to the object being cleaned. Components of surfactants are classified as ionic (anionic, cationic, amphoteric) or nonionic depending on their activity.

![]()

Anionic surfactants

Anionic surfactants have hydrophobic groups that ionize into negative ions (anions). Examples include carboxylates, sulfonates, sulfates, and phosphates.

![]()

Cationic surfactants

Cationic surfactants have hydrophobic groups that ionize into positive ions (cations). Because they have the opposite structure to soap, they are also called invert soaps.

![]()

Amphoteric surfactants

Amphoteric surfactants exhibit anionic surfactant properties in alkaline ranges and cationic surfactant properties in acidic ranges. They are widely used as reinforcing additives.

![]()

Nonionic surfactants

Nonionic surfactants have a non-ionizing hydrophilic group. They can be used in combination with other surfactants and offer excellent penetration, emulsification, dispersibility, and cleaning properties.

Alkaline cleaning chemicals

Alkaline cleaning chemicals increase the negative surface potential between the dirt and the object being cleaned, thereby increasing electrostatic repulsion and improving peelability. Increasing the pH causes the dirt to take on a negative surface potential, inducing electrostatic repulsion. On the other hand, in the case of hetero-aggregates, the charge of particles of the same species induces electrostatic repulsion, while for heterogeneous particles, even if the charges are of the same sign, different amounts of charge induce an attractive force at close range. In terms of intermolecular forces, while they act as an attractive force between molecules of the same species, they can be either an attractive or repulsive force between molecules of different species. It is necessary to comprehensively consider the electrostatic repulsive force and van der Waals force as surface interaction forces. Specifically, microparticles adhered by van der Waals forces may not be detached simply by increasing electrostatic repulsion, so mechanical force, such as ultrasound, is applied. For both interfacial tension and mechanical force to work effectively, it is necessary to select an appropriate cleaning method and optimize the concentration and liquid temperature based on the critical micelle concentration.

Dissolution cleaning

Dissolution cleaning is a cleaning method that removes dirt through the dissolution reaction of cleaning chemicals. Dirt, oil, rust, etc. are dissolved and removed using aqueous cleaning chemicals such as alkaline and acidic, as well as semi-aqueous chemicals and non-aqueous cleaning chemicals (solvents).

Aqueous cleaning chemicals

Fatty acids and other oil components are saponified and dissolved by alkaline chemicals. The alkali reacts with the oil components to turn them into soap, which dissolves in the cleaning liquid. The resulting soap itself is also effective in cleaning. When surfactants are used, oily dirt is also captured inside the micelles and solubilized. Alkaline chemicals are used for finishing cleaning of parts that have water-soluble machining oils. When cleaning metal parts, proper rust prevention measures are required for the material being cleaned, as they may react with alkali and corrode. Acidic chemicals are used to remove rust, inorganic salts, oxide films, and water stains from metals, and to pre-clean before plating. Since rust is the oxidation of metals, they utilize a reducing action. Components such as calcium and magnesium are removed by converting them into chlorides using the action of acid. In addition, chelating agents bind metal ions to form complexes, increasing solubility. Depending on the material of the object being cleaned, there is a possibility of corrosion, so it is necessary to select an appropriate cleaning chemical.

Semi-aqueous cleaning chemicals

Semi-aqueous cleaning chemicals are chemicals that are a blend of aqueous and non-aqueous such as organic solvents. There is no clear definition, but they contain a water content of several tens of percent, and have the advantage of reducing volatile organic compounds (VOCs) compared to solvent-based chemicals. A wide variety of types are available on the market, including glycol ether-based, alcohol-based, terpene-based, and pyrrolidone-based chemicals. Because it has ether and hydroxyl groups in its molecule and is polar and water-soluble, it can dissolve not only oil stains but also water-soluble stains. It is used for removing flux and cleaning cutting oil in metal processing. When cleaning metal parts, there is a risk of rust, so appropriate rust prevention measures are required for the material.

Non-aqueous (solvent-based) cleaning chemicals

Cleaning chemicals whose main ingredient is an organic solvent are collectively called non-aqueous or solvent-based chemicals. In some cases, organic solvents are used as the sole ingredient. Solvent-based chemicals include alcohol-based, hydrocarbon-based, and halogen-based (fluorine-based, chlorine-based, bromine-based) chemicals. They have the advantage of excellent solubility and no liquid properties.

Alcohol-based cleaning chemicals

Alcohol-based cleaning chemicals have the advantage of being low in toxicity and having little effect on the human body. they have excellent penetration, making them suitable for cleaning small areas. Alcohol is hygroscopic, so there is a risk of rust and stains. Its ability to dissolve oils and fats is weaker than other organic solvents. Because it is flammable, safety measures such as explosion-proofing are required for cleaning systems.

Hydrocarbon-based cleaning chemicals

Based on their molecular structure, hydrocarbon-based cleaning chemicals are broadly classified into four types: normal paraffin, isoparaffin, naphthenic, and aromatic. They have high solubility in oils and fats, and excellent penetration, giving them excellent cleaning performance. They also have the advantage of drying faster than aqueous and semi-aqueous chemicals. They are low in toxicity, relatively inexpensive, and can be recycled by distillation. Hydrocarbon-based cleaning chemicals are flammable, so safety measures such as explosion-proofing are required for cleaning equipment.

Fluorine-based cleaning chemicals

Fluorine-based cleaning chemicals include HFE (hydrofluoroether) and HFO (hydrofluoroolefin). They are non-flammable, have high thermal and chemical stability, and are low in toxicity. Fluorine-based cleaning chemicals have excellent penetration properties, so they are used to remove particles from precision parts. They have low latent heat of vaporization and are excellent at drying, but are expensive cleaning chemicals. They are used in the draining and drying process after water cleaning, substitution after hydrocarbon cleaning, and vapor drying (co-solvent cleaning).

Chlorine- and bromine-based cleaning chemicals

Chlorine- and bromine-based cleaning chemicals are non-flammable and have high thermal and chemical stability. They have excellent cleaning properties and dry quickly. They also have low surface tension, allowing for high penetration. Chlorine-based cleaning chemicals are relatively inexpensive, while bromine-based chemicals are expensive. They are harmful to humans and the environment, and violate the PRTR Act and other environmental laws.

Other organic solvents such as IPA, toluene, methylene chloride, acetone, and ethanol may also be used as single cleaning chemicals.

Summary

- There are three types of dirt: water-soluble organic dirt, oil dirt, and solid contaminants. There are also combinations of these types.

- Cleaning methods are broadly divided into stripping and dissolution.

- Cleaning chemicals should be selected based not only on price, but also on consumption efficiency and recyclability.

- Cleaning chemicals are classified as aqueous, semi-aqueous, and non-aqueous (solvent-based), and each has its own appropriate use.

Below is a table summarizing the types of dirt contaminants, and the effectiveness of cleaning chemicals.

*Results may vary depending on the usage environment and the characteristics of the individual cleaning chemicals.

| Liquid type | Cleaning chemical | Type of dirt | Remark | |||||

| Oils and fats (water-soluble) | Oils and fats (oily) | Flux | Ions | Particles | Metal | |||

| Aqueous | Neutral/Alkaline | ○ | △ | △ | △ | ○ | X | – |

| Acidic | △ | X | X | △ | △ | ○ | – | |

| Semi-aqueous | Glycol ether-based | △ | △ | ○ | ○ | ○ | X | – |

| Terpene/Pyrrolidone-based | △ | △ | ○ | ○ | △ | X | – | |

| Non-aqueous | Alcohol-based | △ | ○ | △ | △ | △ | △ | Explosion proof |

| Hydrocarbon-based | X | ○ | ○ | X | X | X | Explosion proof | |

| Fluorine-based | X | △ | △ | X | X | X | Environmental measurement | |

| Chlorine/Bromine-based | X | ○ | ○ | X | X | X | Environmental measurement | |

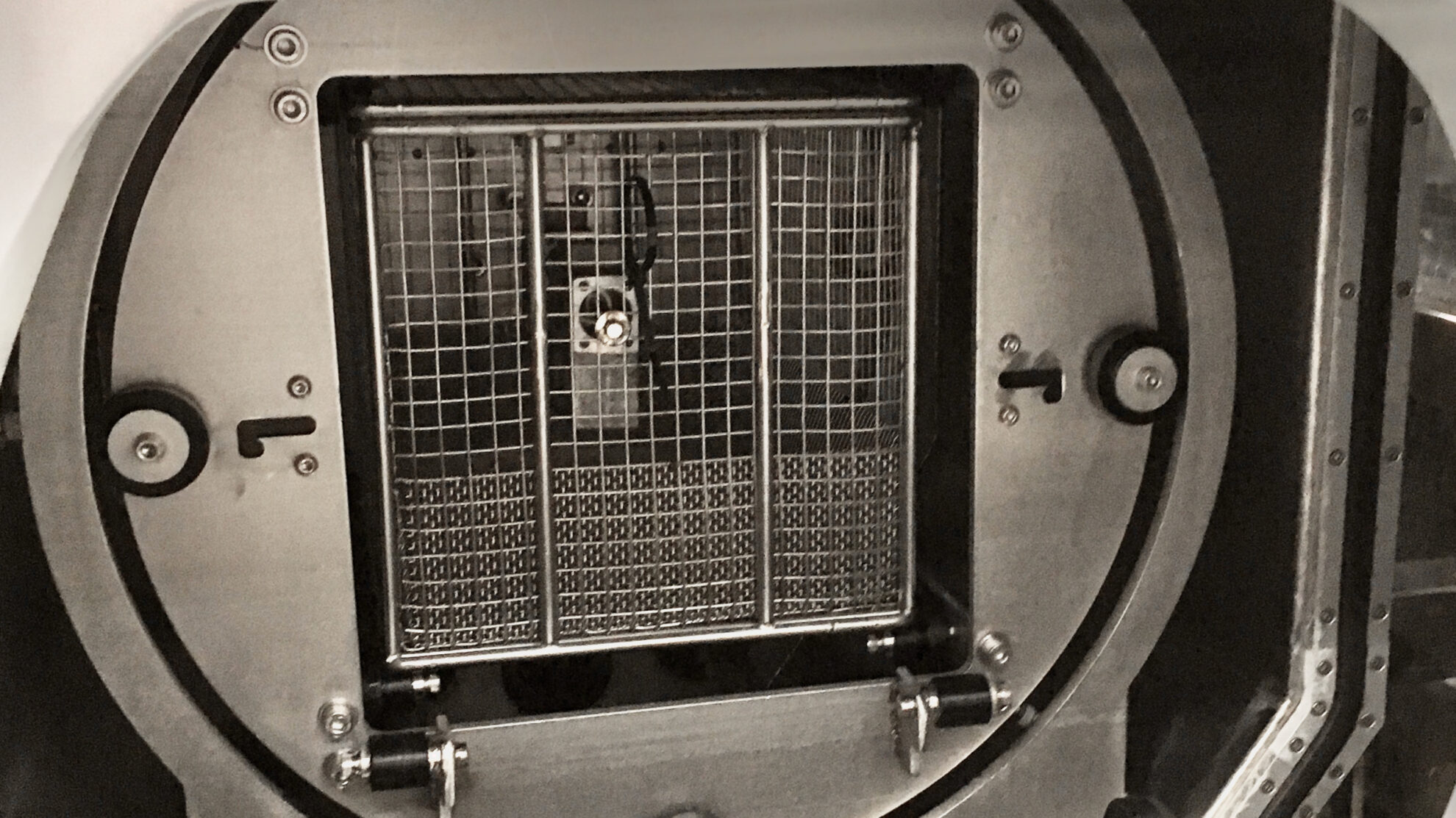

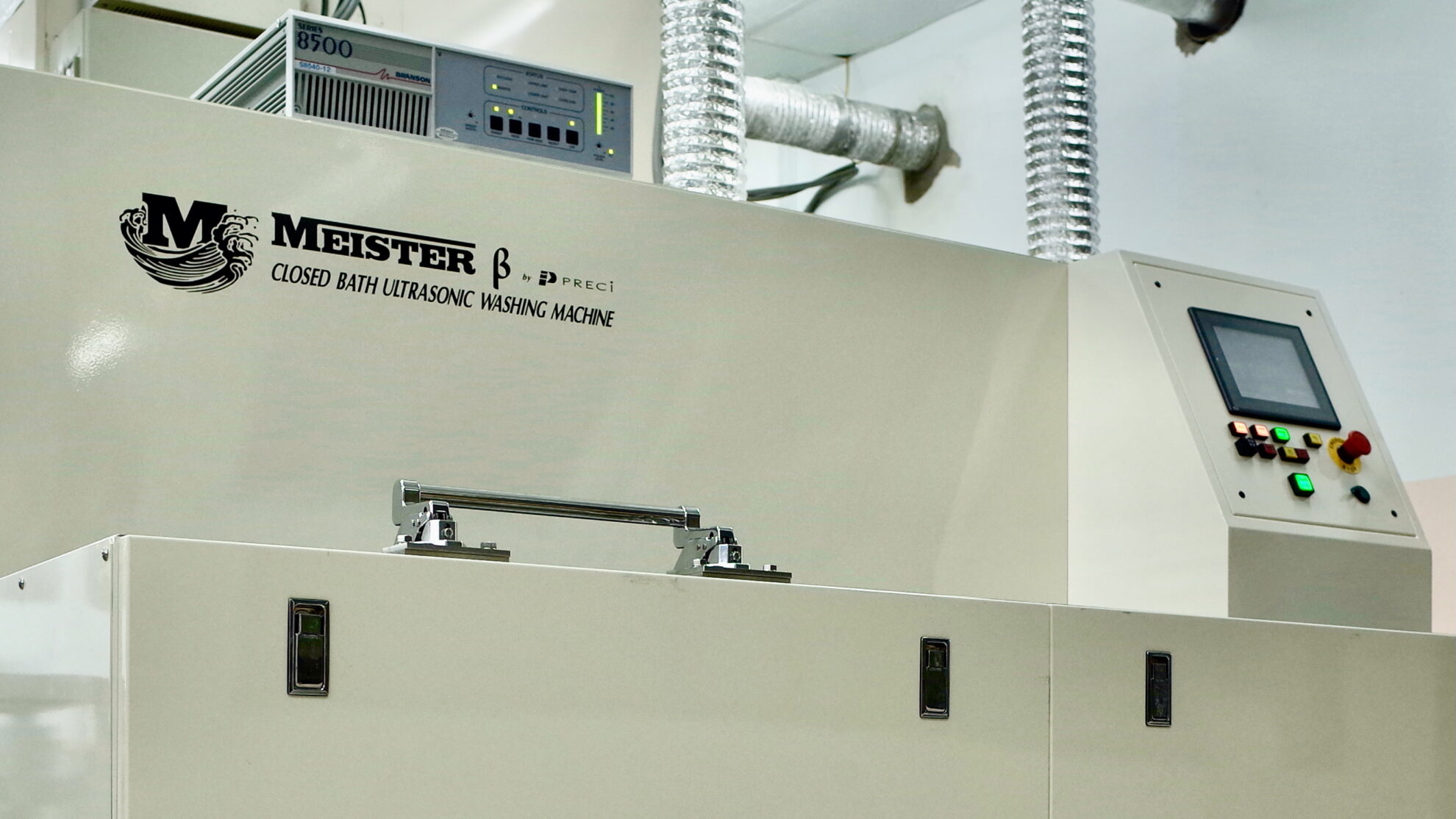

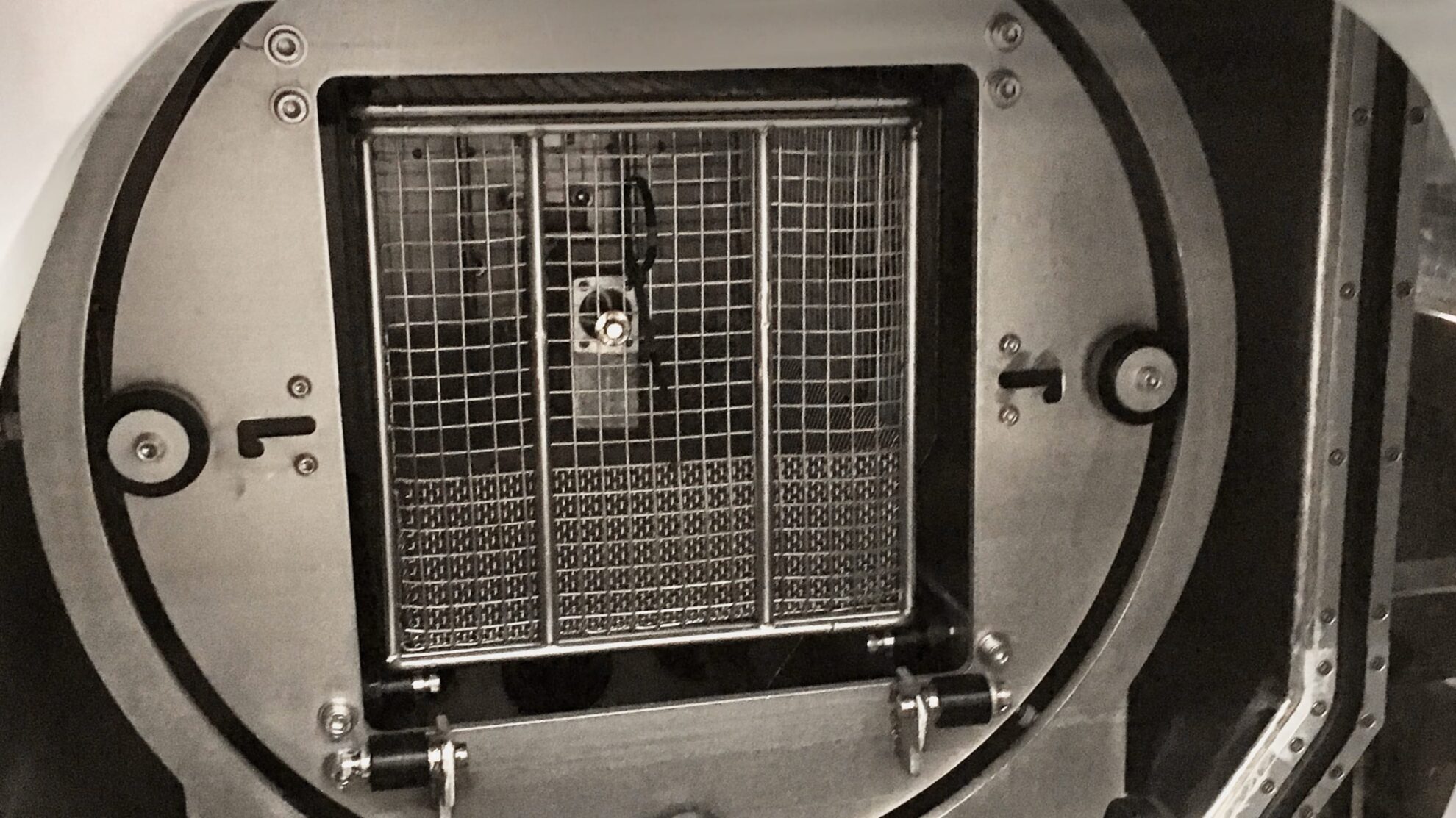

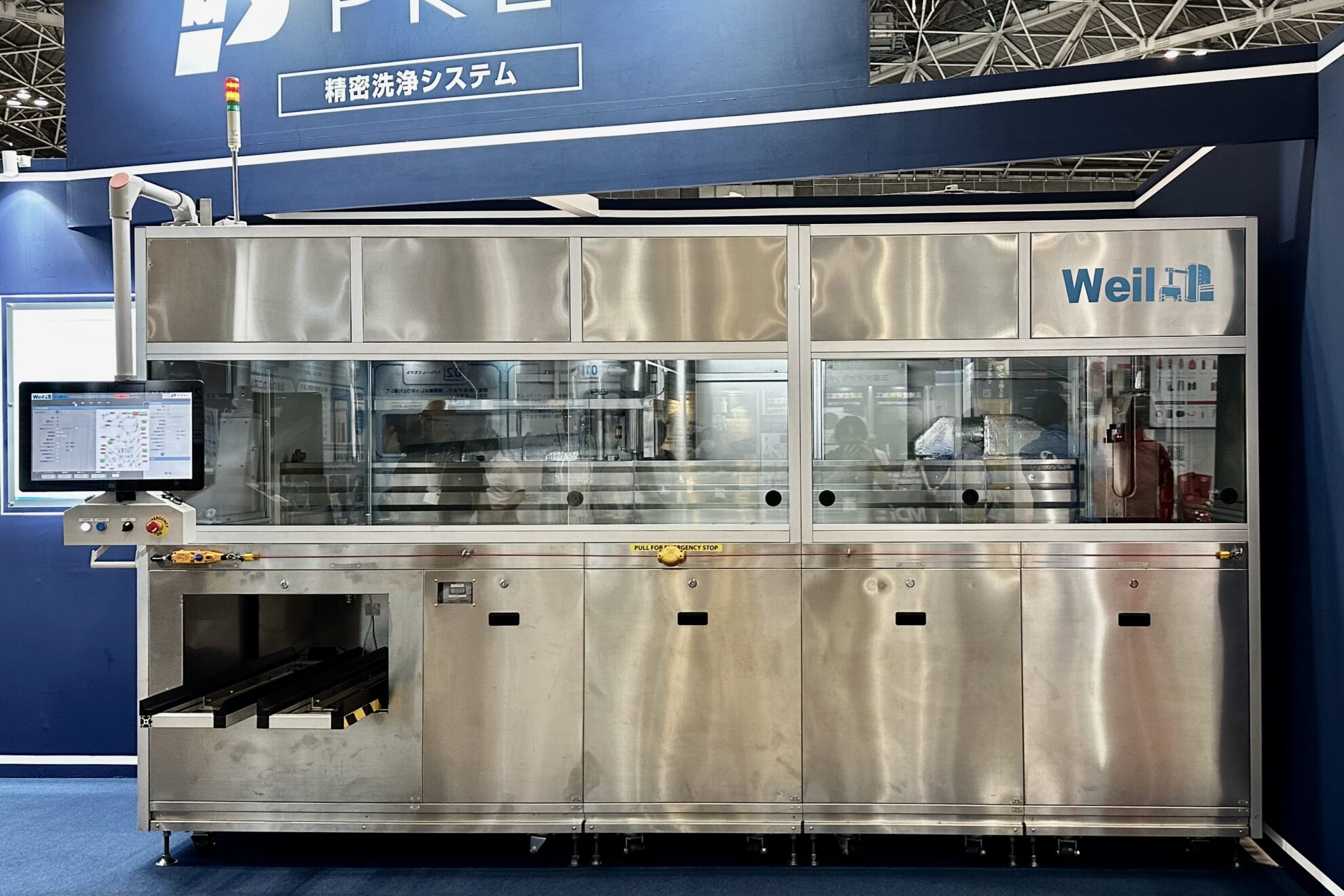

We provide precision cleaning processes that combine high cleaning performance with environmental friendliness. We handle a wide range of cleaning methods, including ultrasonic, spray, shower, submerged jet, barrel, degassing, vacuum, and combinations of these methods. We design processes that minimize the consumption of cleaning chemicals and operating costs, such as electricity consumption. Ancillary equipment includes dehydration, vacuum drying, vapor drying, concentration, filtration, distillation regeneration, pure water production and regeneration, etc., depending on the applications. Conveyor systems can be selected from among net conveyor, basket, hoop, etc. Cleaning processes can be controlled from manual to full automation. It is also possible to implement the minimum level of automation according to the budget constraints. Recipe and lot management, communication between pre- and post-processes, and communication with the user’s central control system can also be supported.

Our cleaning test center (CTC) offers cleaning trials using actual workpieces, as well as analysis and measurement services. Through partnerships with a wide variety of cleaning chemical suppliers, we rationally determine and propose the most cost-effective chemicals in terms of performance.