Our large-scale shakers boast unrivaled robustness and stability thanks to our accumulated shaking technology. Shakers often operate continuously 24 hours a day, sometimes for weeks at a time, so the equipment must be robust and trouble-free. Some of our incubator shakers, which are in operation around the world, have been in operation for over 60 years. We continue to provide maintenance services for these long-lived shakers operating around the world.

Large-scale and high-speed rotary shaking technology dates back to Takasaki Scientific Instruments, the predecessor of our Bioprocesses department, which was founded in 1914. In 1946, at the request of the General Headquarters of the Supreme Commander for the Allied Powers (GHQ), industry, government and academia began working together on the industrial production of high-quality penicillin. Takasaki Scientific Instruments began developing a penicillin incubation equipment, completing the swing-type incubator as its first machine. Since then, Takasaki Scientific Instruments has earned overwhelming trust and recognition for the quality and robustness of its large shakers, as evidenced by the large number of long-lasting shakers still in operation at customer sites. Since absorbing Takasaki Scientific Instruments’ bioprocesses business in 2010, we have continued to improve our technologies by incorporating our own technologies into the shaking technology that has been accumulated over many years. Our large-capacity and high-speed shaking technology, capable of handling shaking diameter at 70 mm and maximum rotation speed up to 400 rpm, has made us gain higher international recognition.

One of our customers, a Japanese pharmaceutical manufacturer, has been using our large shakers for many years in their incubator processes of biopharmaceuticals. While the standard diameters of a incubator shaker is around 10 to 50 mm, our incubator shakers can accommodate up to 70 mm. The customer’s process uses our products compatible with 70 mm diameter because the operating conditions with a 70 mm diameter and a rotation speed of 250 rpm offer higher production efficiency than other conditions. From a technical standpoint, the larger the shaking diameter and the higher the rotation speed, the greater the centrifugal force, so precise technics are required in the manufacturing of incubator shakers. Furthermore, unlike small benchtop shakers, these shakers can be loaded with hundreds of flasks at a time, so the greater the load, the more precise the balance of the rotating parts must be. Our incubator shakers are highly rated by customers for their robustness, allowing for stable operation without breakdowns, even in large-capacity, high-speed rotation conditionss that require advanced technologies. In addition to regular maintenance services, we also support calibration and validation processes, supporting our customers’ production processes for many years.

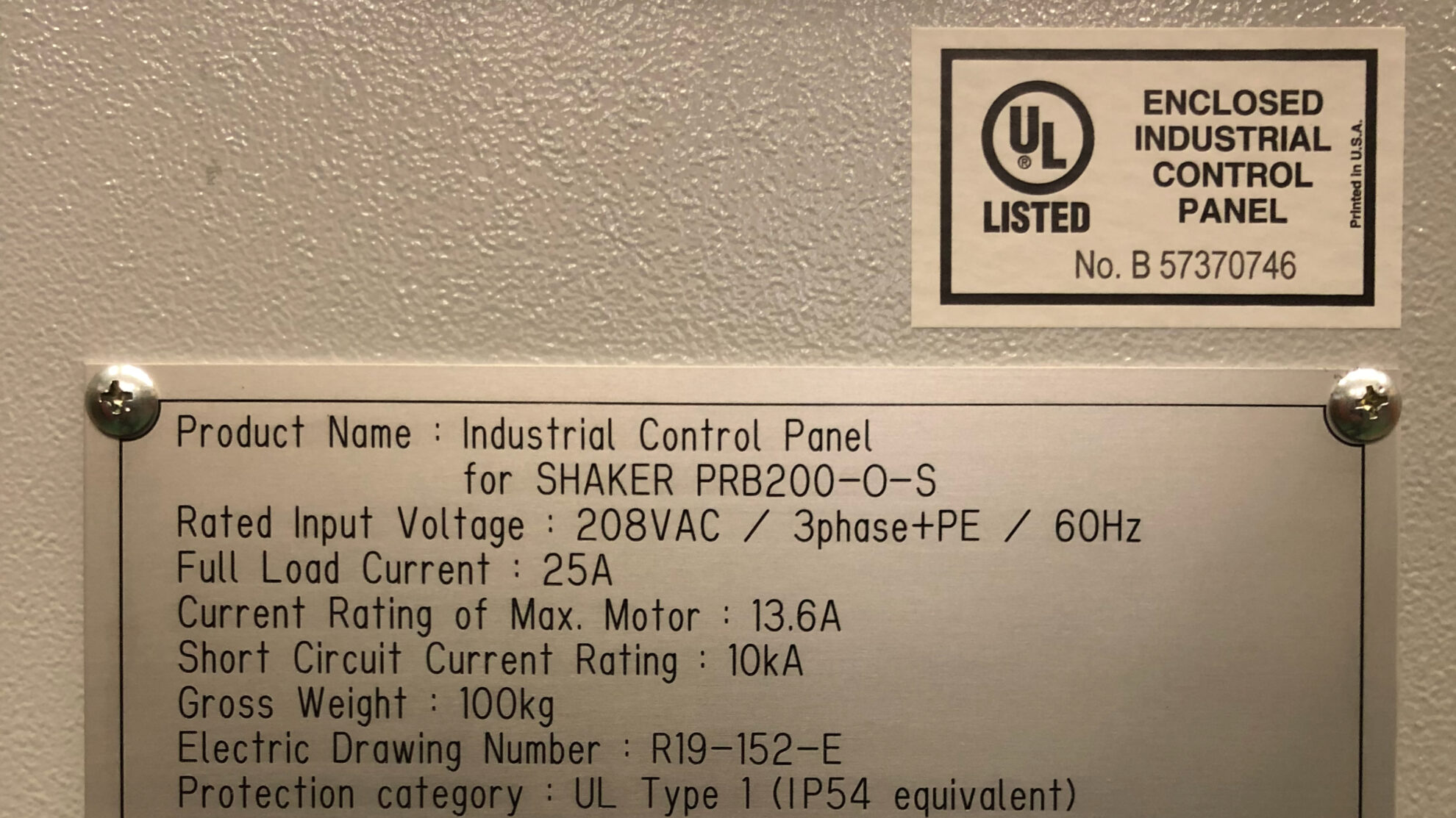

One of our customers, an American pharmaceutical company, develops pharmaceutical applications by combining its own drug delivery system (DDS) technology with approved active pharmaceutical ingredients (APIs), and has an extensive technology portfolio for liposomes. In 2019, the customer found our shaking technology through an introduction from one of their suppliers and contacted us. They were looking for a shaker capable of operating at high speed to handle the number of vials required for the product preparation process, but were unable to find a manufacturer with the technical capabilities to meet their needs. The technical standards required by the customer were extremely high, with a plan to operate a shaker 24 hours a day for 10 days at a high speed of 400 rpm, handling 5,000 vials per batch (total weight 200 kg). After conducting in-house technical studies, we determined that we could meet the requirements, and the project officially began. After going through basic designing, safety risk assessment, environmental compatibility verification, and regulatory compliance, we moved on to the design and manufacturing process. However, with the spread of COVID-19 in 2020, the project management became increasingly difficult. Although we encountered issues such as delays in parts delivery, we successfully completed the shaker and followed by its test run operation. However, due to travel restrictions imposed in various countries amid the pandemic, it became impossible to conduct on-site acceptance inspections. After discussions with the customer, we conducted FAT, IQ, OQ, and SAT remotely online, and successfully completed the inspection process. The customer transitioned to commercial operation as planned, and is continuing stable production even under large-volume, high-speed rotation conditions.

We offer a wide range of shaking processes for a variety of applications, including incubator shakers for culturing aerobic microorganisms, platelet storage shakers, industrial waste leaching, and soil sample extraction. Shaking methods include reciprocating, rotating, and multi-way. We also offer a wide range of options, including precise temperature control and light source irradiation. We create optimal aeration and culture conditions to suit the shape of flasks, tubes, and vials.