Drug delivery systems (DDS) are a technology that aims to enhance medicinal efficacy and reduce side effects by delivering the active ingredients of drugs to the target location at the right time and in the right amount. Advances in nanotechnology have made it possible to process materials at the atomic level, leading to advances in technology that encapsulates drugs in nano-sized carriers and transports them appropriately to the target location. For example, research and development is underway to realize anti-cancer drug treatment with reduced side effects by delivering and acting only on cancer cells. The nanotechnology-based DDS market is expected to expand at a rate of 9% per year, reaching US$200 billion by 2032.

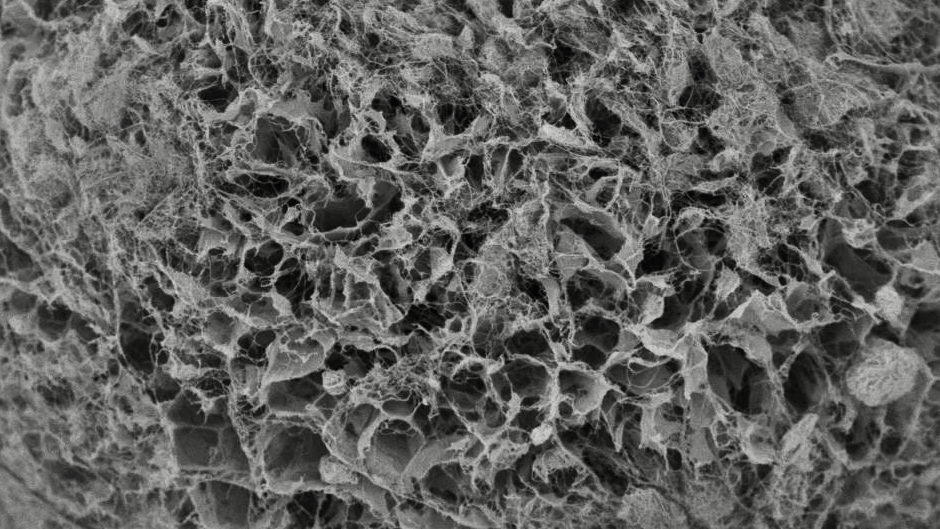

Liposome formulations are a type of DDS technology. Human cells are separated by biological membranes, which prevent the intrusion of foreign substances from the outside world while also allowing substances to enter and exit the outside world. The barrier of the biological membrane is a lipid bilayer (closed vesicle) composed mainly of phospholipids. Liposomes mimic the lipid bilayer function of biological membranes. Liposomes are known to have excellent biocompatibility and a low risk of causing allergies. Currently, technological development is underway to adjust the size of liposomes at nano level and to control their duration and timing of action.

One of our customers, an American pharmaceutical company, develops drugs by combining its drug delivery system (DDS) technology with approved active pharmaceutical ingredients (APIs), and has a rich technology portfolio in liposomes. In 2019, the customer found our technology through an introduction from its supplier and we received their inquiry thanks to the introduction. They were looking for a possible shaking technology that could operate at high speed to handle the number of vials required for their product preparation process all over the world, but they were unable to find a suitable manufacturer.

Our large-scale shakers are recognized as the most robust and reliable products in Japan. After their contact to us, we started reviewing their requirements. The technical standard required by the customer was very high: 5,000 vials per batch (total weight 200 kg) were planned to be run at 400 rpm for 24 hour/10 day cycle continuous operations. After conducting our in-house technical review, we determined that it was possible to meet the requirements, and the project officially began.

When exporting products to the United States, there are certification systems such as OSHA (Occupational Safety and Health Administration), NRTL (National Recognized Testing Laboratories), UL (Underwriters Laboratories), ANSI (American National Standards Institute), and NFPA (National Fire Protection Association). Through smooth communication with the customer, we were able to proceed from basic design through safety risk assessment, environmental compatibility verification, and regulatory compliance verification, before moving on to detailed design and the manufacturing process. Then, in 2020, the spread of the novel coronavirus disease (COVID-19) made project management difficult. Although issues arose, such as delays in the delivery of some components, the product was successfully completed. However, as travel restrictions began to be imposed in various countries amid the pandemic, it became impossible to carry out on-site acceptance inspections. After consultation with the customer, we successfully completed online remote FAT (Factory Acceptance Inspection), IQ, OQ, and SAT (Site Acceptance Inspection), and the product passed the final inspection. The customer then transitioned to commercial operation as planned, and is continuing stable production to this day.

Our large-scale shakers are recognized as the most robust and reliable products in Japan. With our accumulated technological background since 1950’s, we have kept maintaining the existing shakers over the country including 60 years old shakers that are still in operation. We offer a wide range of shaking processes for a variety of applications, including incubator shakers for culturing aerobic microorganisms, platelet storage shakers, industrial waste leaching, and soil sample extraction. Shaking methods include reciprocating, rotating, and multi-way. We also offer a wide range of options, including precise temperature control and light source irradiation. We create optimal aeration and culture conditions to suit the shape of flasks, tubes, and vials.

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.