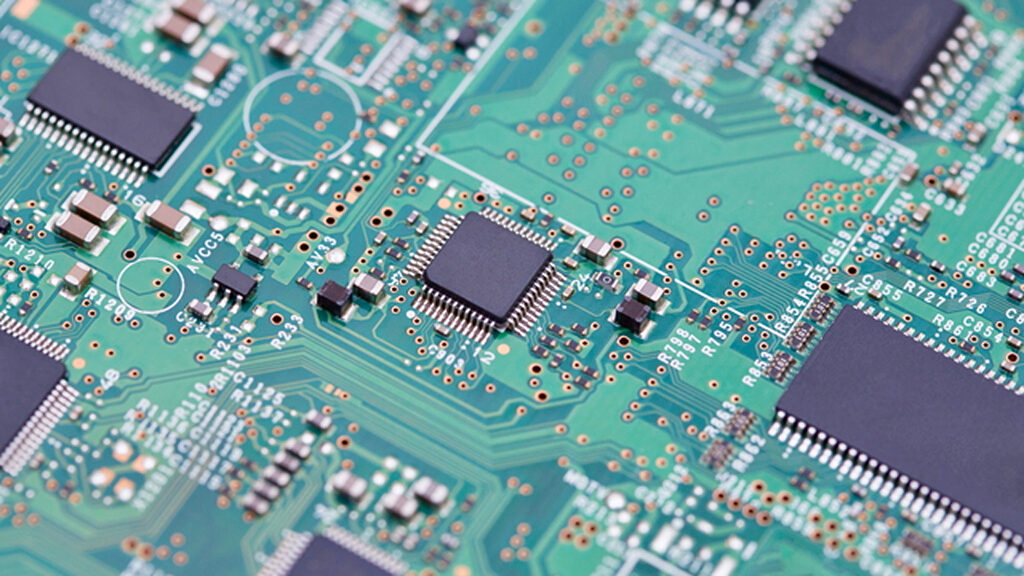

Defluxing is a process used in the electronics industry to remove flux residue that is generated during soldering of printed circuit boards, electronic component boards, semiconductor packages, etc. In addition to promoting the wetting and spreading of molten solder, flux also serves to remove the oxide film on the surface of the base material, preventing re-oxidation of the molten solder and the base material surface. After the soldering process, flux residue remains. Flux residue contains various activators and metal salts which may cause problems such as poor connections, contact failures, and corrosion. Therefore, if there is a possibility that it could have a negative impact on product quality or the manufacturing process, it must be removed.* There is also a type of flux called pre-flux, which is used as an anti-rust surface treatment for copper on a circuit board, but this article explains post-flux, which is used during a soldering process.

Flux is a general term for soldering accelerators, and is broadly divided into the following three types based on their main components.

Resin-based flux

Resin-based fluxes are primarily composed of rosin, modified rosin, and synthetic resin. Resin-based fluxes contain organic solvents, activators such as organic acids, amines, and their halides, as well as thixotropic agents for viscosity adjustment. Also known as rosin-based flux, it is widely used in electronics assembly processes, such as on printed circuit boards for electronic components.

Organic acid-based flux

The main component is either water-based or solvent-based. Activators include organic acids, amines, and their halides, as well as thixotropic agents for viscosity adjustment. Among organic acid-based fluxes, those based on water-soluble polymers containing organic activators are called water-soluble fluxes.

Inorganic acid flux

Inorganic acid fluxes use inorganic acids or inorganic salts as activators. The activators are dissolved in water, glycerin, wax, etc. Inorganic acid fluxes are not used for mounting printed circuit boards or electronic components.

Fluxes are usually used as a solder paste mixed with solder powder and selected according to the individual soldering conditions required, such as the temperature conditions during preheating and the heat capacity of the components. Environmentally friendly fluxes such as halogen-free and low VOC are also available.

Cleaning chemicals used in the deflux process are broadly classified into aqueous, semi-aqueous, and solvent-based. The required cleaning chemicals vary depending on the soldering conditions and subsequent storage conditions, but the following cleaning chemicals are commonly used.

Aqueous/semi-aqueous cleaning chemicals

There are neutral and alkaline aqueous and semi-aqueous cleaning chemicals designed for flux removal. Semi-aqueous cleaning chemicals are a blend of aqueous cleaning chemicals and non-aqueous cleaning chemicals such as organic solvents. They have the advantages of being safe and environmentally friendly, but they generate a high amount of waste liquid.

Solvent-based cleaning chemicals

Solvent-based cleaning chemicals are hydrocarbon-based, bromine-based, and fluorocarbon-alternative cleaning chemicals. Since chemical properties differ depending on the type of solvents, the appropriate chemicals must be selected taking into consideration the type of flux, cleaning performance, safety, and environmental aspects. Hydrocarbon-based cleaning chemicals have high resin solubility, but are less effective at removing ions. They are low in toxicity, relatively inexpensive, and can be recycled by distillation. Hydrocarbon-based cleaning chemicals are flammable, so explosion-proofing and other safety measures are necessary. Bromine-based and fluorocarbon-alternative cleaning chemicals are non-flammable and have high thermal and chemical stability, making them safe. However, they can have an impact on the human body and the environment, so appropriate environmental measures are required.

Deflux cleaning methods

The following are typical flux cleaning methods:

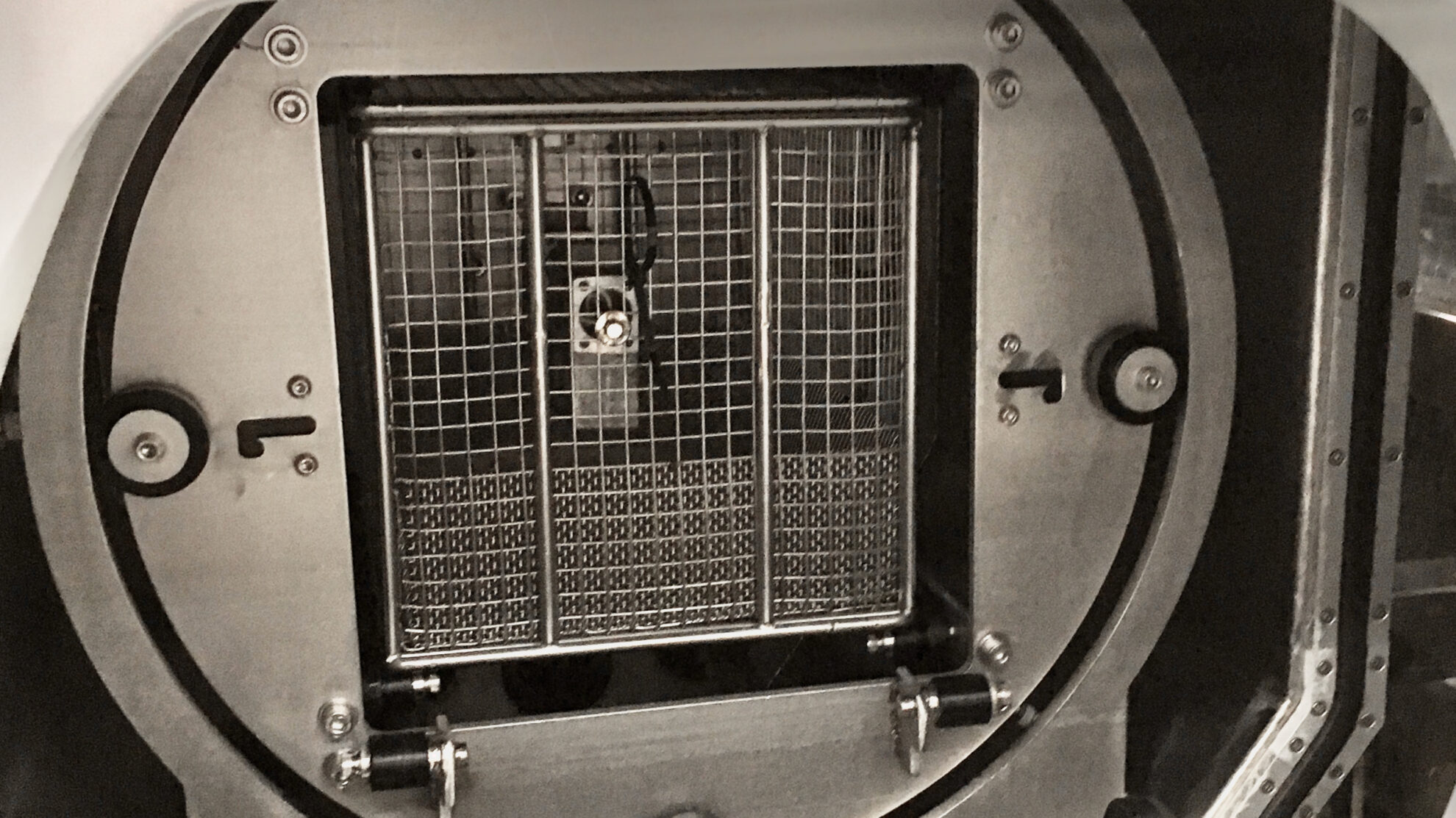

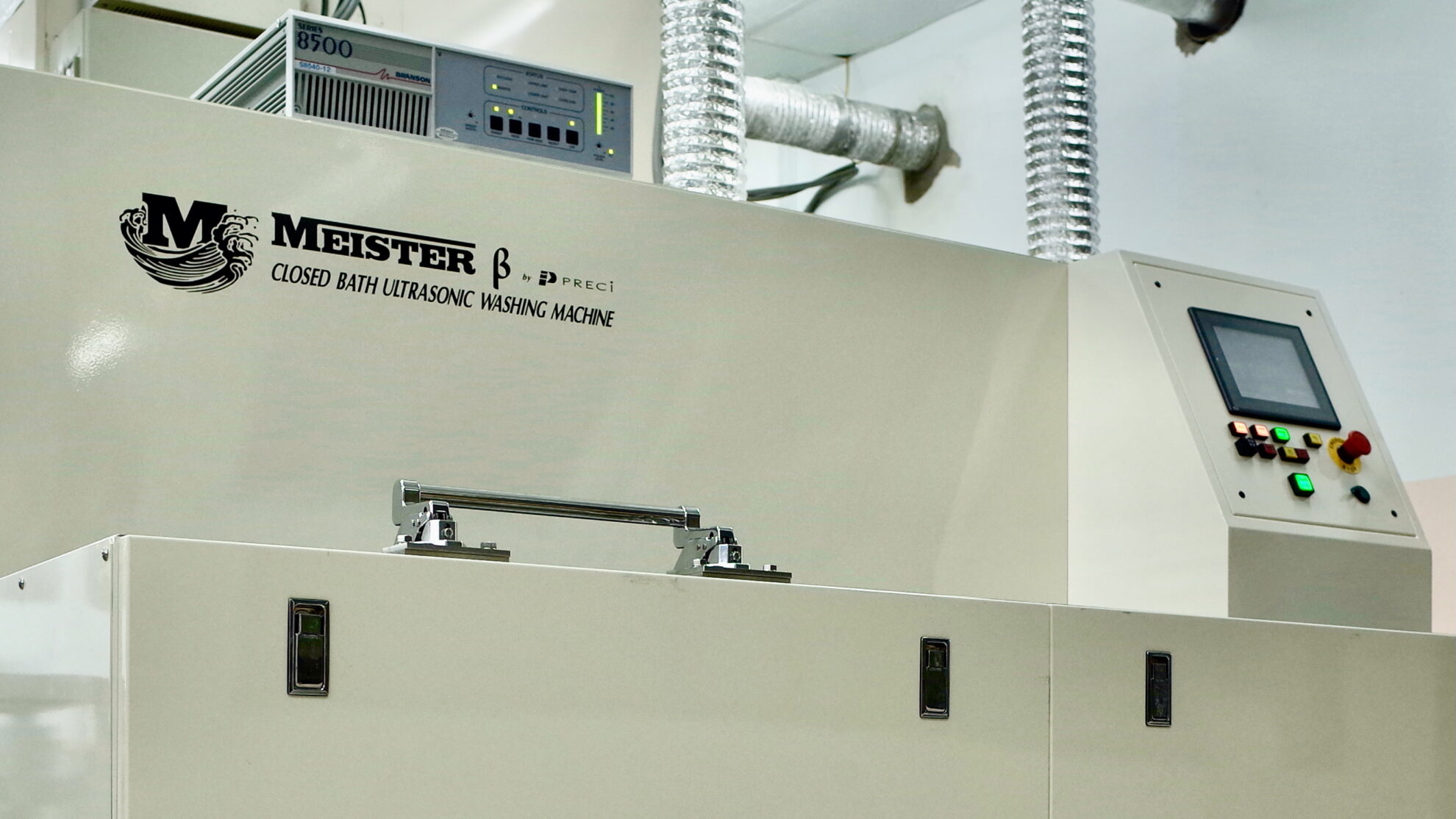

Ultrasonic cleaning

In ultrasonic cleaning, the object to be cleaned is immersed in a liquid and the liquid is vibrated using ultrasonic waves to remove adhering flux residue. Cleaning chemical is filled in a cleaning tank equipped with an ultrasonic vibrator that emits ultrasonic waves, and the object is immersed in the liquid. The ultrasonic vibrator generates the ultrasonic waves electrically using a separately installed ultrasonic oscillator. The operating frequency of the ultrasonic cleaning is selected taking into consideration the material and strength of the object being cleaned, as well as the degree of adhesion of flux residue.

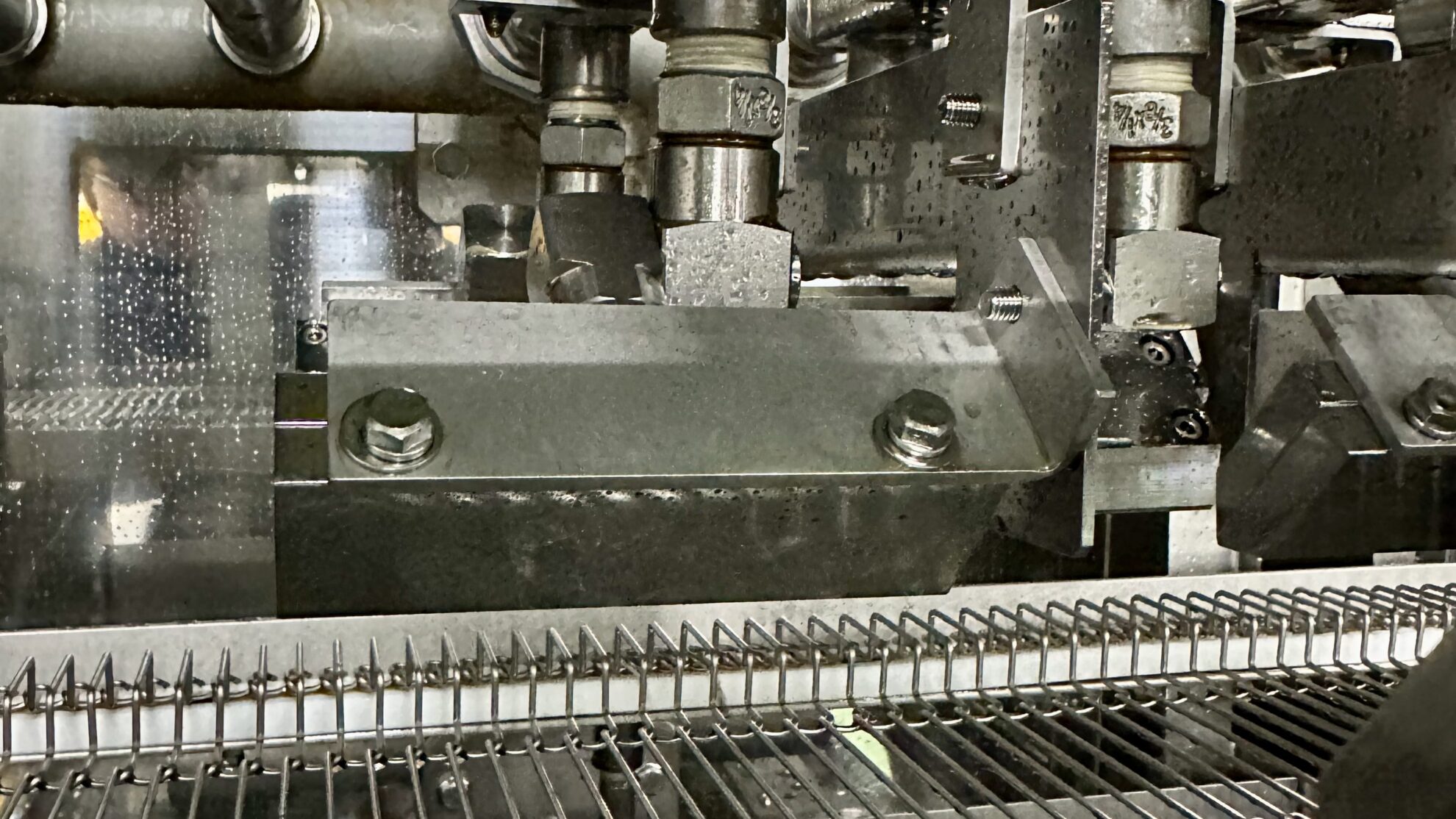

Shower/spray cleaning

Flux residue is removed by spraying cleaning chemical liquid from nozzles onto the object. The flux residue is washed away by the sprayed liquid, so it is less likely for the residue to re-adhere. The physical cleaning performance can be changed by adjusting the nozzle type and spray pressure. Since the cleaning chemical is sprayed from the air, the layout of nozzles and the angle must be optimized to ensure uniform liquid contact to the object. The process is primarily designed as an in-line system integrated with a conveyor system.

Immersion/submerged jet cleaning

The object to be cleaned is immersed in a cleaning tank filled with cleaning chemical, and the flux residue is peeled off and removed mainly by the chemical action of the cleaning chemical. The cleaning performance of immersion cleaning is determined by the concentration of the cleaning chemical, the liquid temperature, and the immersion time. There is also submerged jet cleaning, which uses a liquid flow. The object to be cleaned is immersed in a liquid and a liquid flow is generated by a pump to clean the object. Compared to ultrasonic cleaning or shower/spray cleaning, the physical action is relatively weaker and the cleaning performance is inferior, but the damage to the object is less. Another advantage is that it creates less foam than shower cleaning, which sprays water from the air.

We provide precision cleaning processes that combine high cleaning performance with environmental friendliness. We handle a wide range of cleaning methods, including ultrasonic, spray, shower, submerged jet, barrel, degassing, vacuum, and combinations of these methods. We design processes that minimize the consumption of cleaning chemicals and operating costs, such as electricity consumption. Ancillary equipment includes dehydration, vacuum drying, vapor drying, concentration, filtration, distillation regeneration, pure water production and regeneration, etc., depending on the applications. Conveyor systems can be selected from among net conveyor, basket, hoop, etc. Cleaning processes can be controlled from manual to full automation. It is also possible to implement the minimum level of automation according to the budget constraints. Recipe and lot management, communication between pre- and post-processes, and communication with the user’s central control system can also be supported.

Our cleaning test center (CTC) offers cleaning trials using actual workpieces, as well as analysis and measurement services. Through partnerships with a wide variety of cleaning chemical suppliers, we rationally determine and propose the most cost-effective chemicals in terms of performance.

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.