Plastics (resins) is a general term for polymeric substances that change shapes when heat or pressure is applied. There are natural resins such as rosin and lacquer, as well as a variety of artificially produced synthetic resins. Based on their physical properties, resins are classified into thermoplastic resins and thermosetting resins.

Thermoplastic resins soften when heated to their glass transition point ( Tg ) or melting point ( Tm ). Thermoplastic resins solidify when they are cooled again. Therefore, by controlling the amount of heat applied, thermoplastic resins may undergo any state change, making them an easily recyclable material. Thermoplastic resins are broadly classified as crystalline or amorphous depending on the degree of orientation of the polymer chains, and exist in liquid, rubbery, glassy, and crystalline states. In crystalline resins, the polymer chains are regularly aligned at temperatures below the melting point. In amorphous resins, the polymer chains are not regularly aligned even in a solidified state below the glass transition temperature. Thermoplastic resins are also classified into general-purpose plastics and engineering plastics depending on their heat resistance. General-purpose plastics include polyethylene (PE), polypropylene (PP), ABS resin, and acrylic resin. Engineering plastics include polyamides (PA) such as nylon, polyethylene terephthalate (PET), polycarbonate (PC), polyether ether ketone (PEEK), polyphenylene sulfide (PPS), polytetrafluoroethylene (PTFE), etc. Thermoplastic elastomers (TPEs), which have the property of softening when heated and returning to a rubbery state when cooled, are also classified as thermoplastic resins.

Thermosetting resins soften when heated, but once they exceed a certain temperature, the reaction between polymer chains progresses to a three-dimensional structure, causing them to harden. Once hardened, resins do not soften even when re-heated. Because the cross-linking between molecules is strong, they are resistant to the effects of temperature changes so that they are difficult to recycle. Typical materials include phenolic resin (PF), epoxy resin (EP), melamine resin (MF), urea resin (UF), thermosetting polyimide (PI), and thermosetting elastomers (saturated/unsaturated).

There are also plastics with added distinctive functions. Environmentally friendly biodegradable plastics, bioplastics, shape memory resins, photocurable resins, and composite materials such as glass fiber reinforced plastics (GFRP), carbon fiber reinforced plastics (CFRP), and recycled wood plastic composites (WPRC) are used in a variety of industries.

Powderization of synthetic resins

Because the physical properties of synthetic resins are diverse, it is important to select an appropriate manufacturing process for powderization. Flakes and powders of resins obtained through a grinding process are pulverized by physical impact, which causes thermal denaturation due to friction. In addition, irregularly shaped particles such as stringy or whisker-like particles are generated during crushing, which tends to result in irregular shapes and poor particle size and uniformity. Our technologies, spray drying, spray congealing, and freeze granulation, allow for precise particle control to produce spherical powders with excellent flowability and a sharp particle size distribution (PSD).

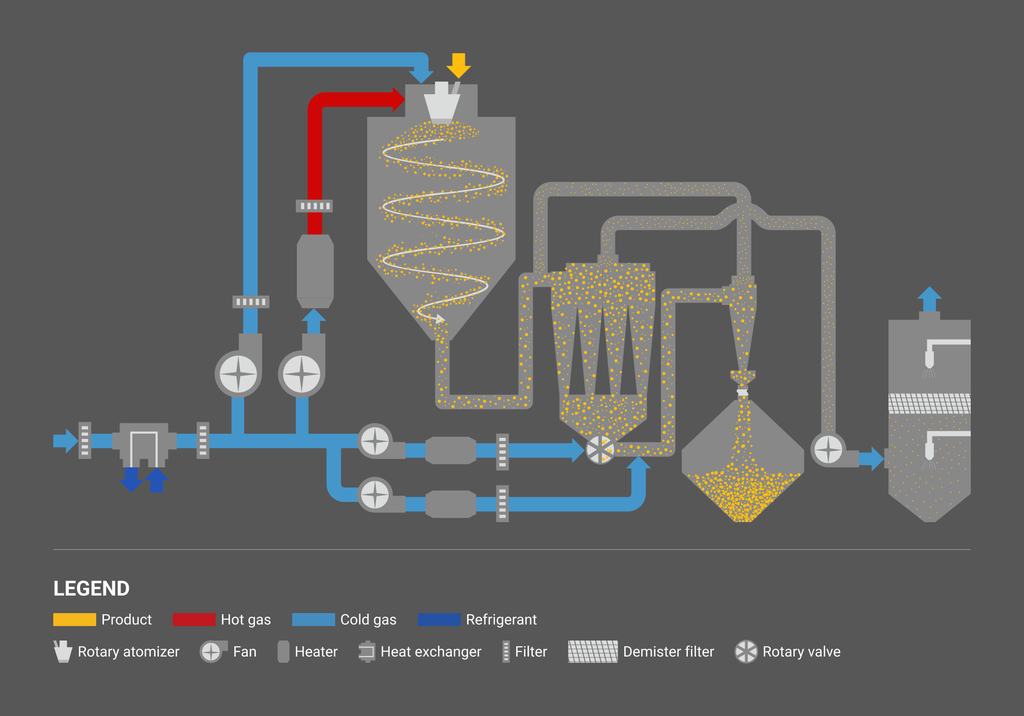

Spray drying

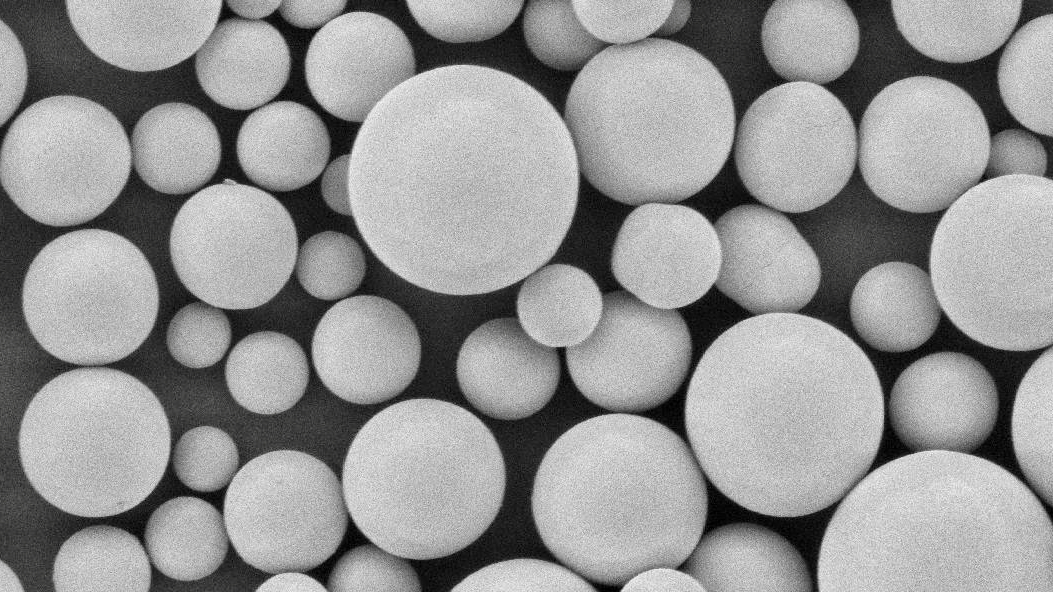

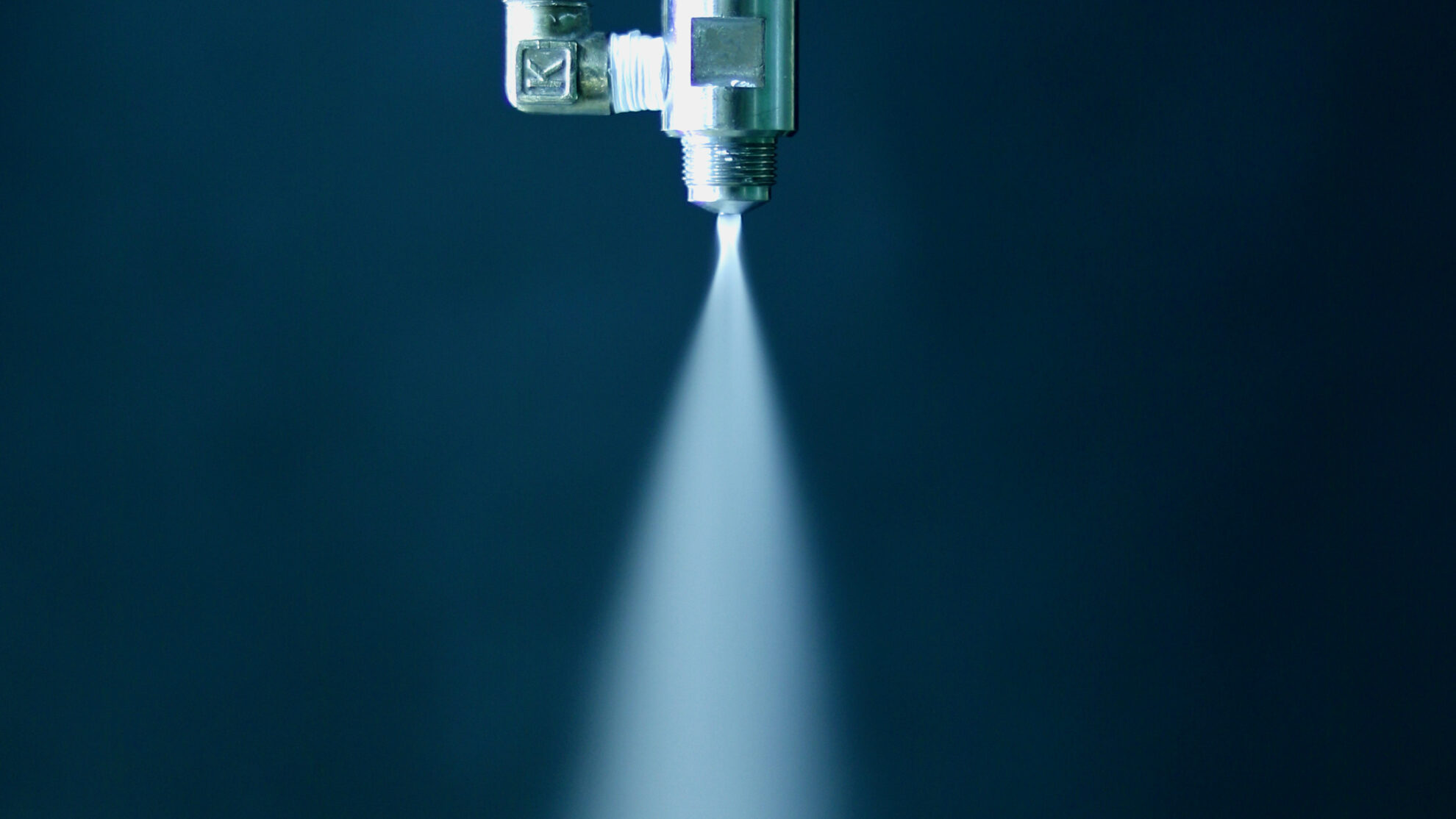

Dried granules obtained by spray drying are spherical and has excellent fluidity, resulting in a sharper and more stable particle size distribution (PSD) than other drying processes. Drying and granulation process of resin raw materials using a spray dryer requires process condition settings based on precise heat balance calculations. For example, for dispersions of thermoplastic resins with low glass transition points ( Tg ) or melting points ( Tm ), it is important to set a process temperature that prevents the powder from softening due to the heat effects during drying, and to properly control the fall-down time of the atomized droplets. To reduce the thermal impact on the raw materials, dehumidified, low-dew-point process gas may be used to keep the drying temperature low. Because spray dryers are a continuous powder manufacturing process that allows for precise particle control, they can continuously produce the desired granules in a single process, rather than a multi-stage processes such as pulverization and classification.

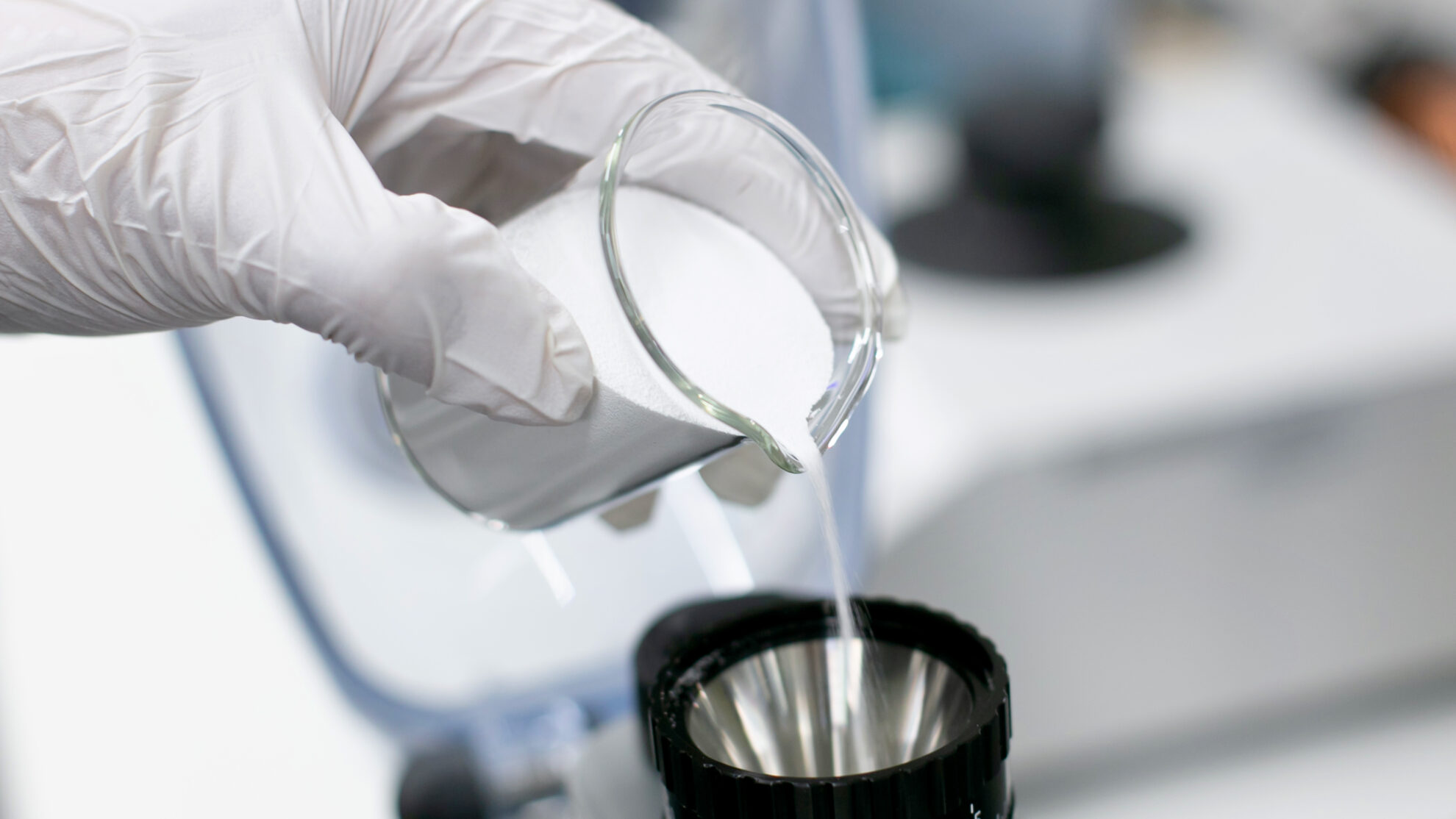

In order to improve production efficiency and granule quality, it is important to optimize process conditions and properly adjust raw materials. When spray drying emulsion dispersions of polymers such as latex, the composition and the amount of surfactants and electrolytes added affect tensile strength and thermal stability. The higher the solids concentration of the dispersion, the higher the production efficiency. However, it must be adjusted appropriately, taking into consideration the viscosity of the liquid, the fluidity, cohesion, and moisture content of the dried powder. When organic solvents are used or oxidation must be prevented, a closed-cycle system using nitrogen as the process gas is used. For thermosetting resins such as phenols and epoxy, process conditions are set taking into account the curing temperature and specific heat. For example, the initial condensation products of melamine resin and urea resin are produced as dry powders by spray drying the resin liquid obtained through a condensation reaction with formalin. It is necessary to minimize the thermal impact on the dried powder. The resin liquid is atomized into a spray dryer process and the moisture immediately evaporates in the upper part of the drying chamber. The dried powder is then rapidly cooled down by cooling air supplied from the lower part of the drying chamber, and is then recovered at a cyclone. We offer optimal spray drying process conditions depending on the quality targets for the physical properties, particle size, shape, etc. of the resin raw materials.

Spray congealing

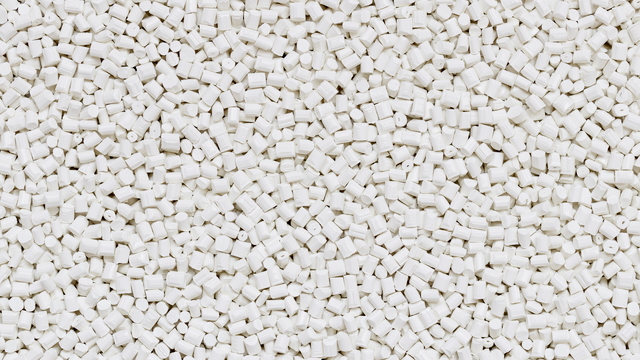

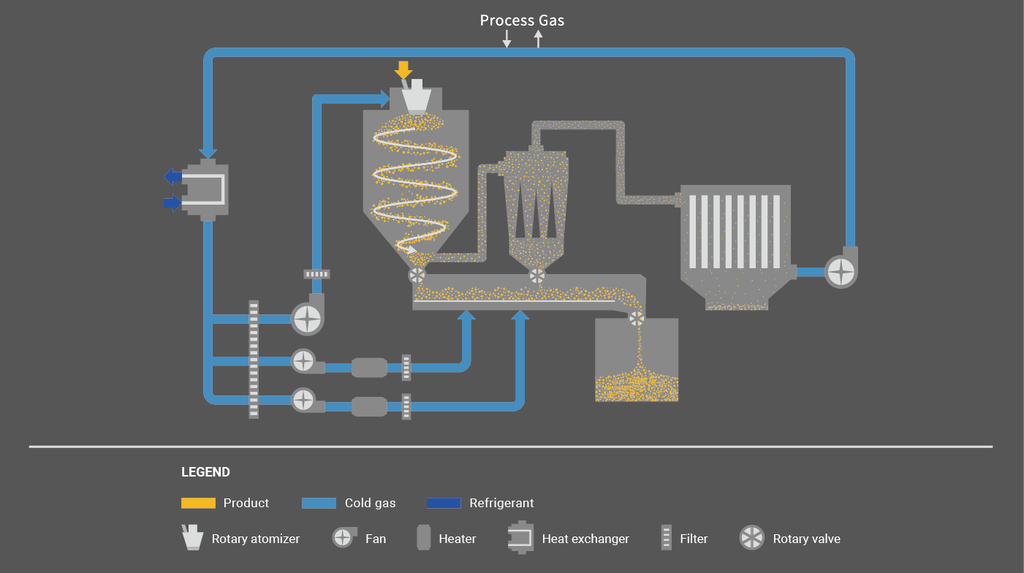

Spray congealing using a spray cooler can granulate thermoplastic resins and turn them into beads or prills. In the case of thermoplastic resins, the heated molten liquid is atomized into a cooling chamber and continuously contacted with a cooling gas stream that is lower than the melting point ( Tm ), producing cooled and solidified granules. The solidified granules are spherical and have excellent fluidity, resulting in a sharp and stable particle size distribution (PSD). Unlike spray drying, the liquid raw material contains almost zero moisture, resulting in larger particle sizes. In general, spray congealing produce granules ranging in size from several tens of μm to several mm.

Spray congealing is a continuous process that allows for mass production of granules in a single process, eliminating the need for downstream processes such as pulverizing, classification, granulation, etc. A spray cooler requires proper adjustment of the liquid raw material and operating conditions. By properly designing a spray congealing process, it is possible to produce granules that meet your specific needs. We propose optimal spray cooler process conditions according to the quality targets such as physical properties, particle size, and shape.

Freeze granulation

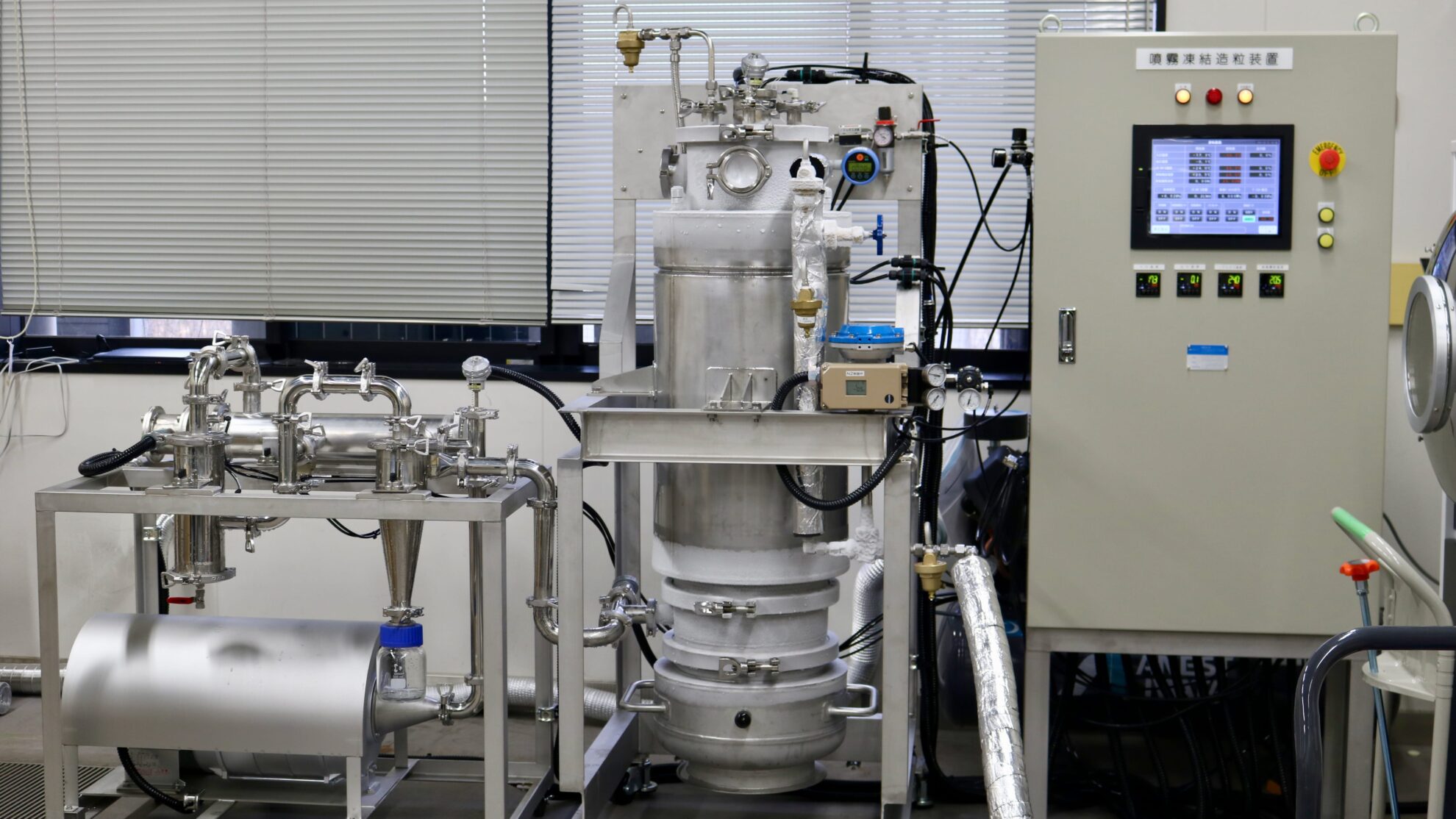

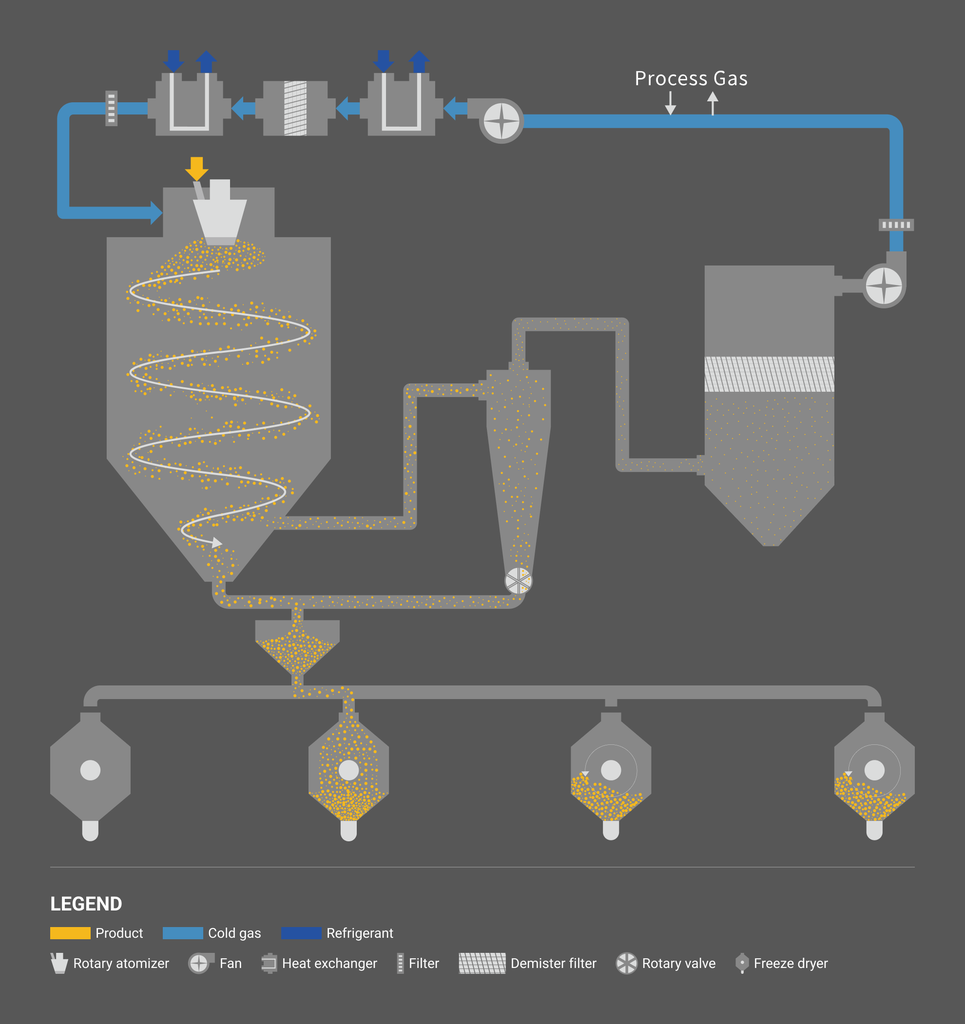

Freeze granulation is a process that produces frozen granules by atomizing a liquid material into an ultra-low temperature environment. The atomized droplets instantaneously get frozen and dried granules are obtained after sublimation process (freeze drying). In 2019, we developed the world’s first production scale dry cooling freeze granulation process. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles.

Freeze granulation process is a two-step powder manufacturing process consisting of a freezing process in which a liquid material is atomized and rapidly cooled down to obtain frozen granules, and a drying process in which the frozen granules are freeze-dried to obtain dried granules. The freezing process is continuous, while the freeze-drying process is batch-based. In order to eliminate the drawback of the batch-type freeze-drying process which is the latter stage, it is possible to process as semi-continuous production by connecting multiple freeze dryers to the freeze granulator and automatically switching connections between them.

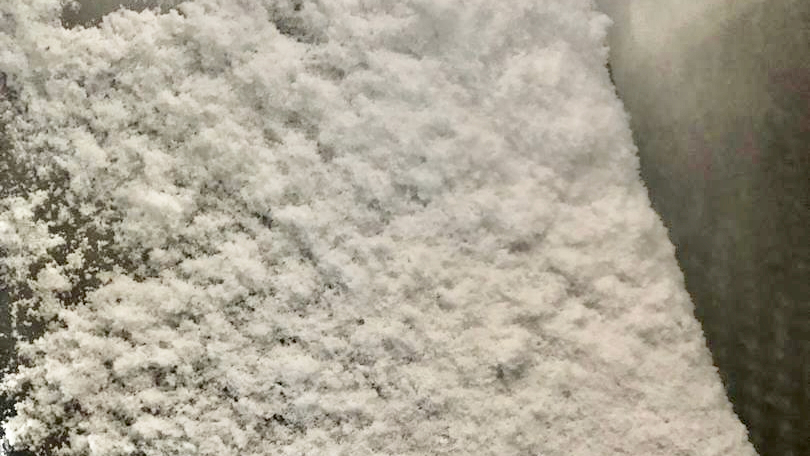

The dried granules obtained by freeze granulation are spherical in shape, have excellent fluidity, and can maintain low density and high homogeneity. The particle size range of the granules is relatively wide, ranging from 10 to 500 µm, and the tap density equivalent to or higher than spray dried powder can be obtained. Additionally, unlike high-temperature hot gas drying processes, there is no heat effect on materials, and oxidation can be minimized.

Freeze granulation is a process that allows for precise particle control, so compared to the grinding process of freeze-dried products, the granules are spherical, have excellent fluidity, and can achieve a sharp particle size distribution (PSD). In addition, our latest freeze granulator CS220 does not use liquid nitrogen as a cooling source and it allows for significant reductions in operating costs compared to the grinding process of freeze-dried products.

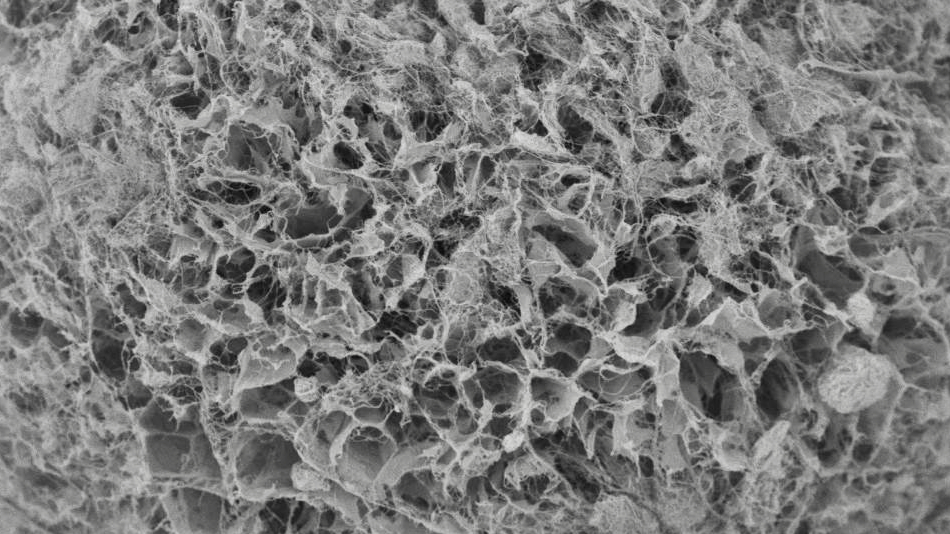

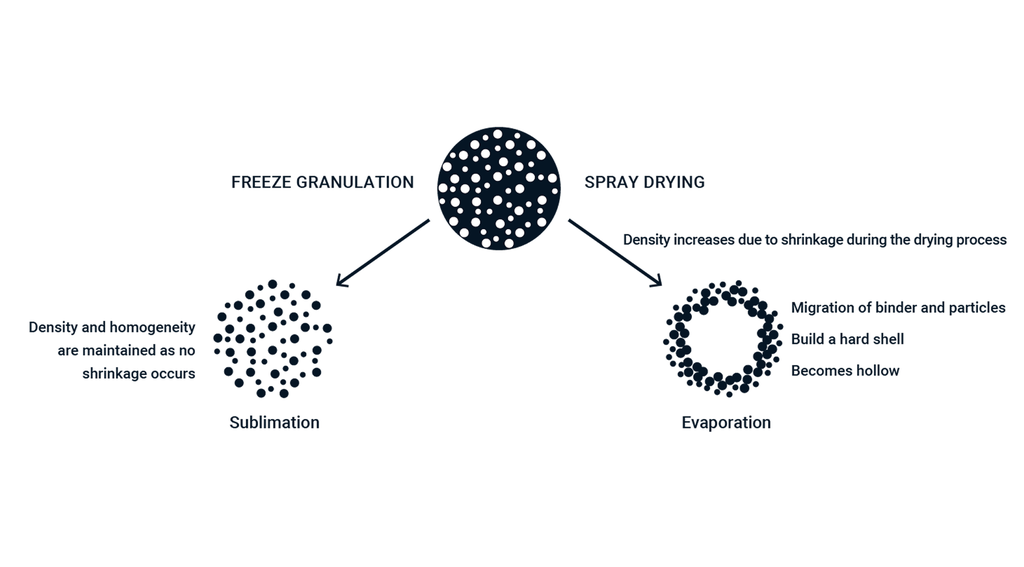

In spray drying, moisture evaporates from the surface of a droplet, and at the same time, internal moisture moves to the surface, causing the droplet to shrink, and the solid inside the droplet to move outward. Therefore, the density of spray-dried granules is higher on the outside surface than inside, so that the shape of the granules may become hollow. Freeze granulation immobilizes the internal structure of droplets containing the moisture by rapidly freezing the droplets. In freeze-drying as the post-process, the frozen moisture (ice) is dried by sublimation, resulting in extremely low material movement and shrinkage. Therefore, the granules are porous but structured, low density with no difference between inside and outside surface.

Because freeze granulation is a new manufacturing process, there are not many application examples at this moment. However, by using a freeze granulator, it is possible to expect an improvement in the quality of products currently produced by spray dryers. Compared to spray drying, there is no heat impact and it is possible to produce low-density, uniform solid granules.

Our spray dryers and spray coolers have a proven track record in plastics. Based on our accumulated experience and expertise, we design optimal spray drying and spray cooling processes and set operating conditions that meet the required quality. By optimizing the various conditions of the processes, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation” and “Dispersibility of Nanofibers – Freeze Granulation of Cellulose Nanofibers (CNF) and Carbon Nanotubes (CNT)“.

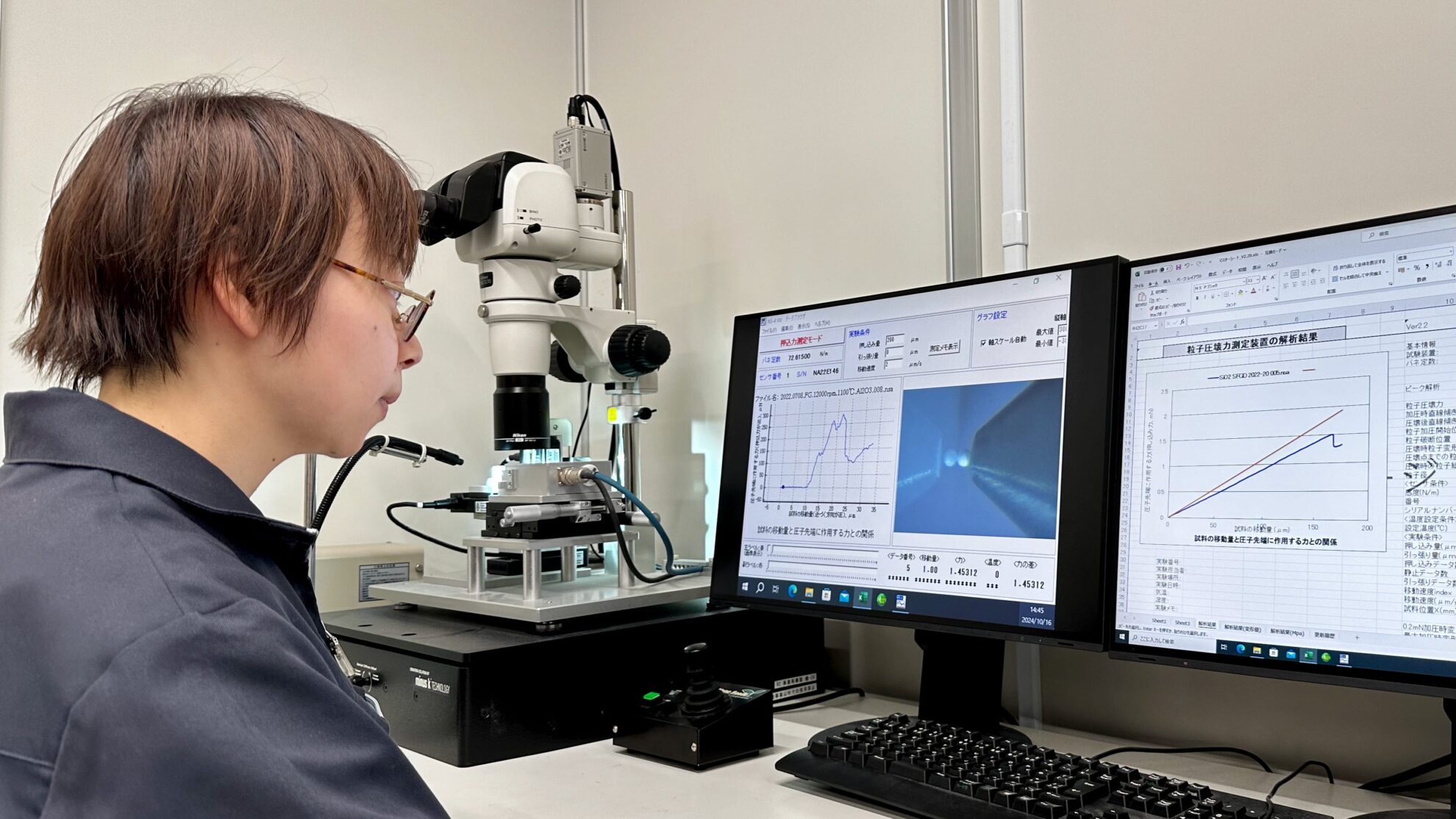

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.