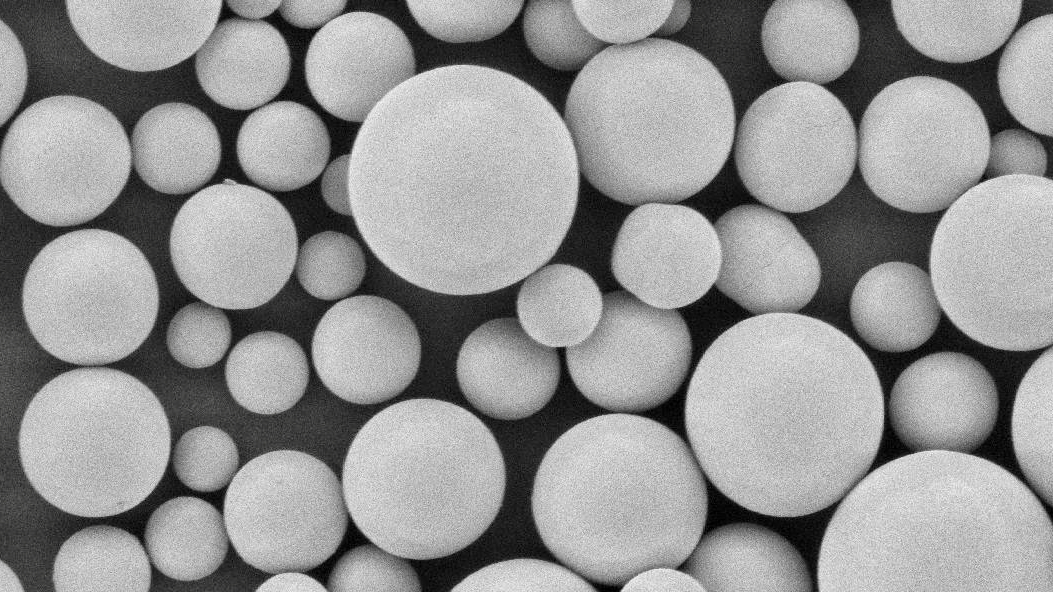

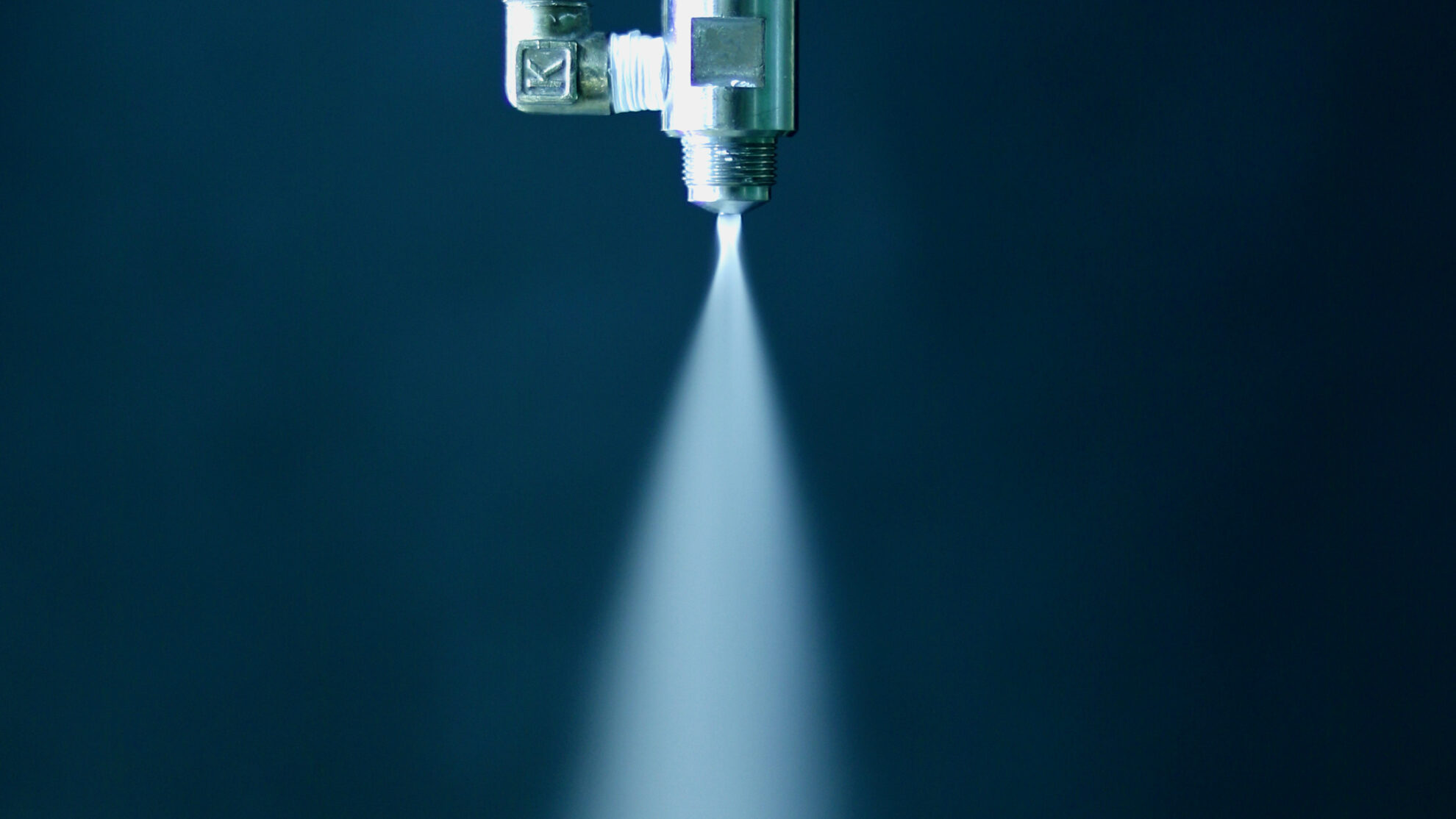

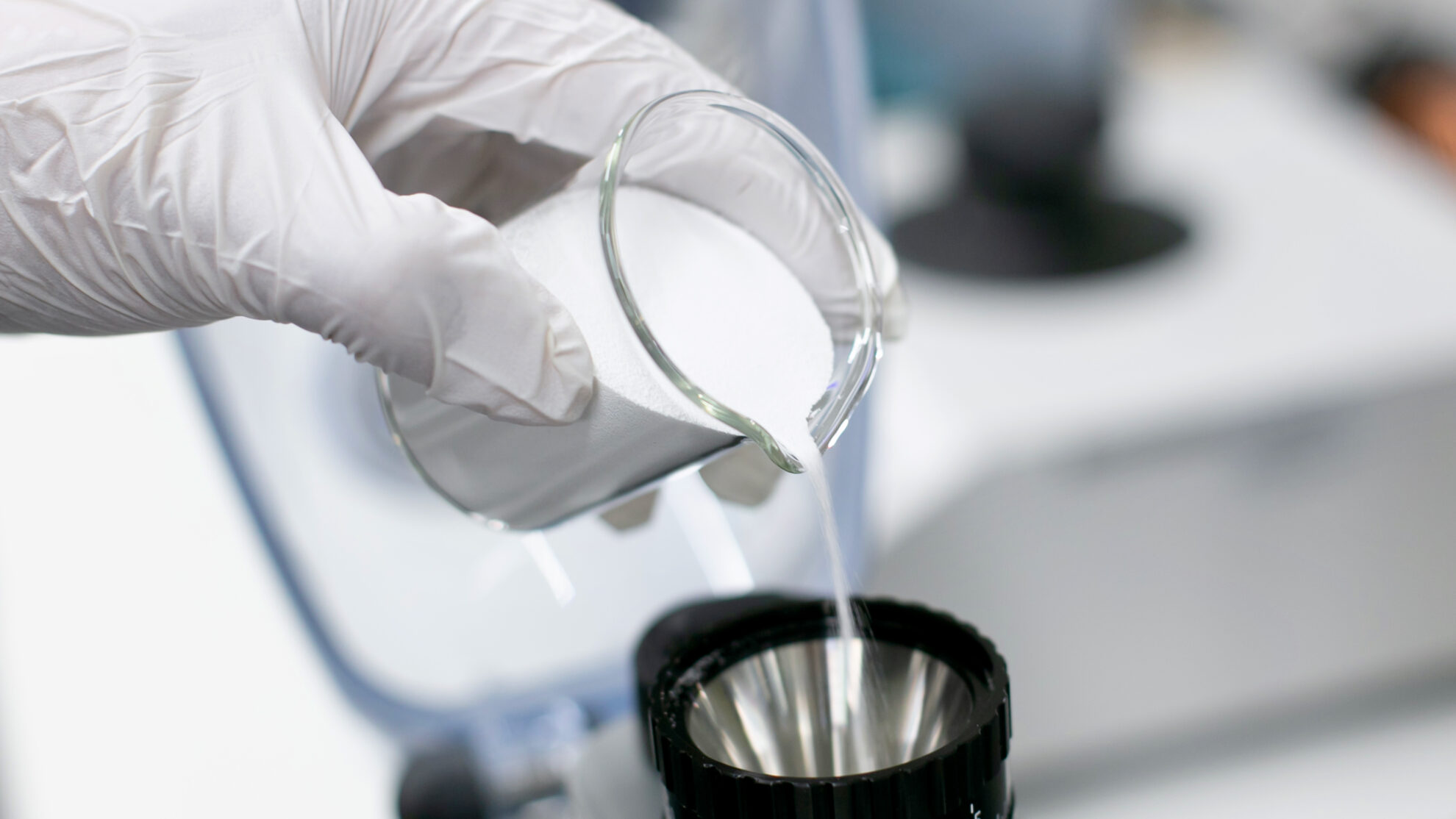

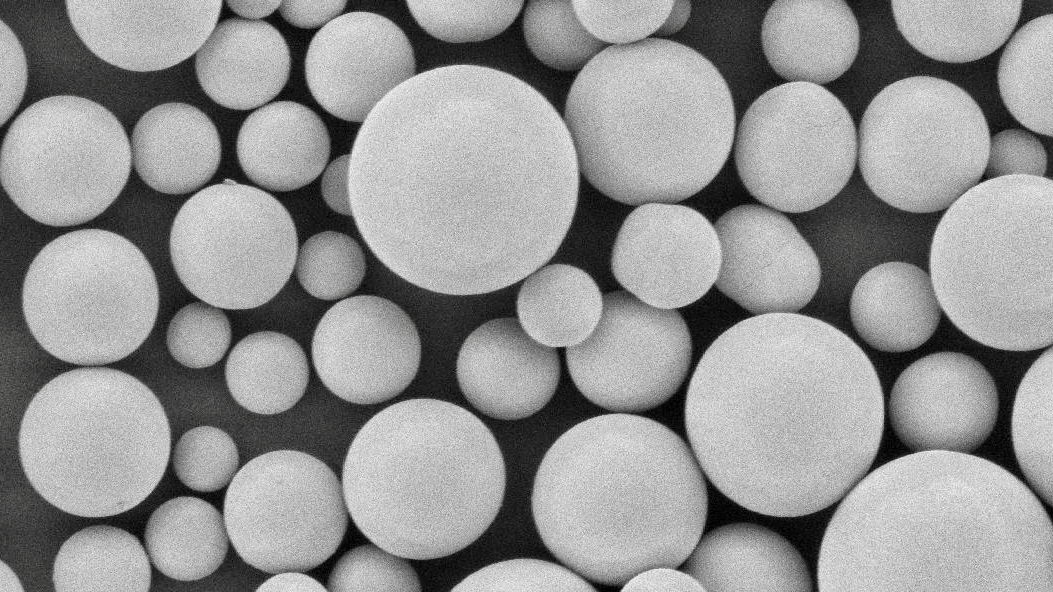

In the manufacturing process of fine ceramics, spray dryers are used in the granule production process. In the wet grinding and mixing process that precedes the spray dryer, a slurry is produced in which raw material powders ranging in size from several hundred nanometers to 1 μm are homogeneously dispersed. The slurry is then spray-dried using a spray dryer to produce granules ranging in size from several tens to 100 μm. By using a spray dryer, the granules become spherical, have excellent fluidity, and have a sharp particle size distribution. This makes it possible to pack the granules uniformly during molding, resulting in a stable molded body with less variation in density or thickness. Furthermore, because the molded body is uniform and high-density, it can be densified with high precision during sintering, resulting in a high-density sintered body with less porosity.

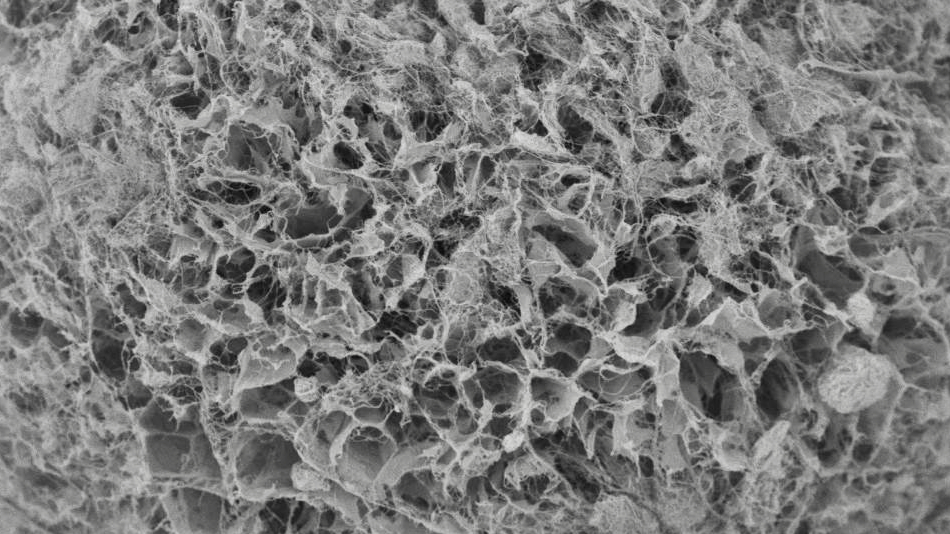

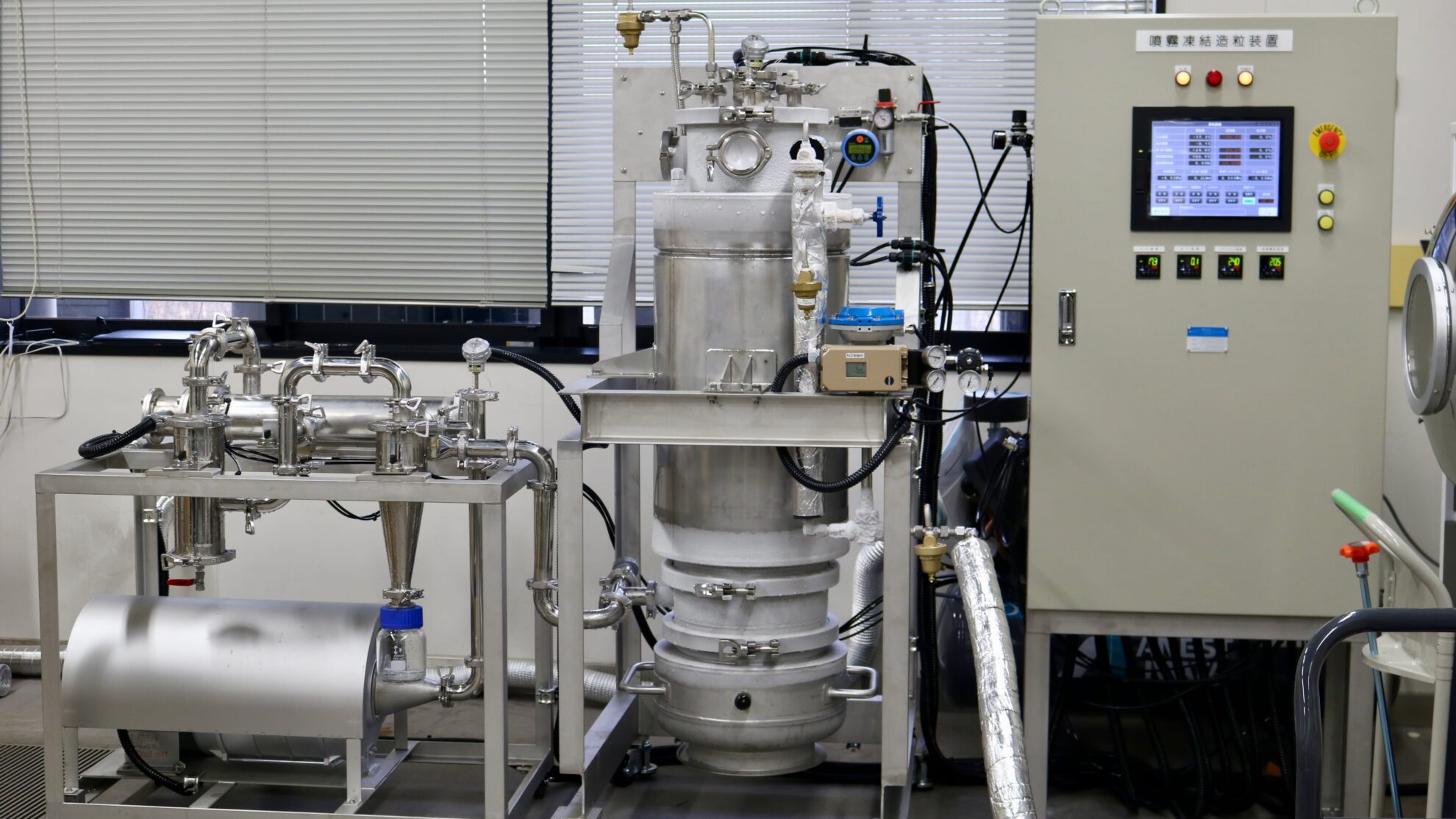

Apart from spray drying, which is widely used in the fine ceramics industry, there is a new granulation process called freeze granulation. Freeze granulation is a process that can produce spherical granules with excellent flowability by atomizing a slurry into ultra-low-temperature environment to instantly freeze atomized droplets, and then sublimating the frozen bodies in the freeze-drying process. In 2019, we developed the world’s first production scale dry cooling freeze granulation process. In 2020, we were awarded jointly with the National Institute of Advanced Industrial Science and Technology (AIST), Yokohama National University, and Yokohama TLO for the FY2020 Strategic Fundamental Technology Advancement Support Project by the Ministry of Economy, Trade and Industry (Project name: Research and Development of Spray Freeze Granulation Drying Process for Advanced Fine Ceramics). In 2023, we developed the large scale freeze granulator CS220 (patented), which uses a dry cooling method with a highly efficient liquid-nitrogen-free cooling unit. The atomization methods can be selected from rotary atomizers, two-fluid nozzles, ultrasonic nozzles, etc., just like with spray dryers.

Freeze granulation process is a two-step powder manufacturing process consisting of a freezing process in which a liquid material is atomized and rapidly cooled down to obtain frozen granules, and a drying process in which the frozen granules are freeze-dried to obtain dried granules. The freezing process is continuous, while the freeze-drying process is batch-based. In order to eliminate the drawback of the batch-type freeze-drying process which is the latter stage, it is possible to process as semi-continuous production by connecting multiple freeze dryers to the freeze granulator and automatically switching connections between them.

Below is one of our studies that we conducted for a comparison of the properties of alumina (Al2O3) and silica (SiO2) produced using the spray drying and the freeze granulation processes.

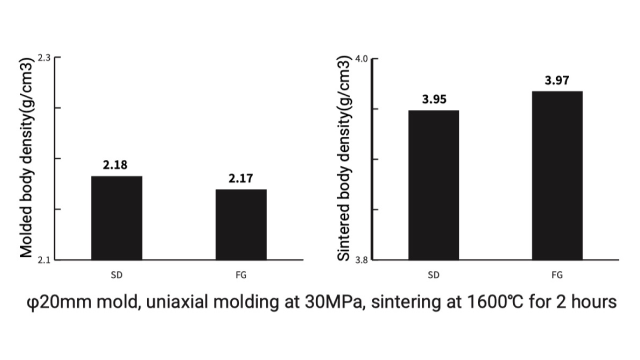

1. Density comparison of alumina (Al2O3) compact and sintered body

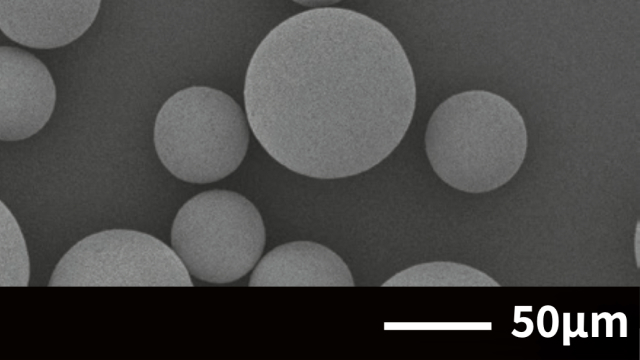

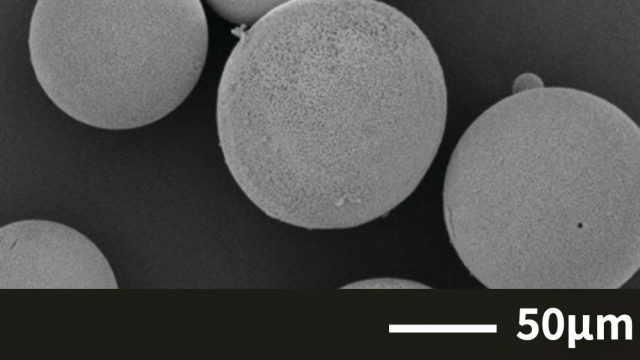

Alumina granules produced by spray drying and freeze granulation were molded using a dry press, and then sintered bodies were produced and their density was evaluated.

Spray drying

Freeze granulation

φ20mm mold, uniaxial molding at 30MPa, sintering at 1600℃ for 2 hours

As a result, the density of the spray-dried granules was high as a compact. However, after sintering, the freeze-granulated granules showed the opposite result, becoming high density. Because the freeze-granulated granules have a homogeneous internal structure and low density, they are less dense when packed into a mold. Therefore, the density of the compact is lower than that of spray-dried granules. On the other hand, freeze-granulated granules have a homogeneous interior, which means that defects are less likely to occur during sintering, resulting in a higher density as a sintered body.

The following is the result of research conducted by the National Institute of Advanced Industrial Science and Technology (AIST), Yokohama National University, and PRECI, with Naoki Kondo of the Multi-Materials Research Division at AIST as the first author. We delivered the first freeze granulator CS30 to AIST in 2022.

Journal of the Ceramic Society of Japan(2024, Full paper)

In this paper, we compared the compactability and sinterability of alumina granules prepared by spray freeze granulation drying (SFGD) and spray drying (SD). We evaluated the strength of the granules, the densities of the compacts and sintered bodies, the pore size distribution of the compacts, and the internal structure and strength of the sintered bodies produced by SFGD and SD granules. The strength of the SFGD granules was lower than that of the SD granules. The lower granule strength of the SFGD granules was advantageous for forming a homogeneous structure without interparticle pores in the green body, resulting in higher density and strength of the sintered body.

* In this page, “spray freeze granulation drying (SFGD)” as described in the paper is referred to as “freeze granulation”.

Reference:

KONDO, Naoki, et al. Compactability and sinterability of alumina granules made by spray freeze granulation drying and spray drying. Journal of the Ceramic Society of Japan, 2024, 132.4: 145-151.

Journal of the Ceramic Society of Japan(2020, Technical report)

Comparison of alumina granules prepared by spray freeze granulation drying and spray drying

In this technical report, alumina granules were prepared using spray freeze granulation drying (SFGD) and spray drying (SD) processes, and the granule properties, including granule size distribution, packing density, angle of repose, and compressive strength were analyzed. Powder compacts were also prepared from SFGD and SD granules, and the corresponding densities and defects were evaluated. Furthermore, these compacts were sintered, and their density and strength were evaluated. Because SFGD granules were produced by freezing slurry droplets, it was found that the properties of SFGD granules were affected by the solid content of the slurry. Sintered bodies made from SFGD granules showed higher strength than sintered compacts made from SD granules, due to the weak and homogeneous granules produced using SFGD.

* In this page, “spray freeze granulation drying (SFGD)” as described in the paper is referred to as “freeze granulation”.

Reference:

KONDO, Naoki, et al. Comparison of alumina granules prepared by spray freeze granulation drying and spray drying. Journal of the Ceramic Society of Japan, 2020, 128.11: 922-926.

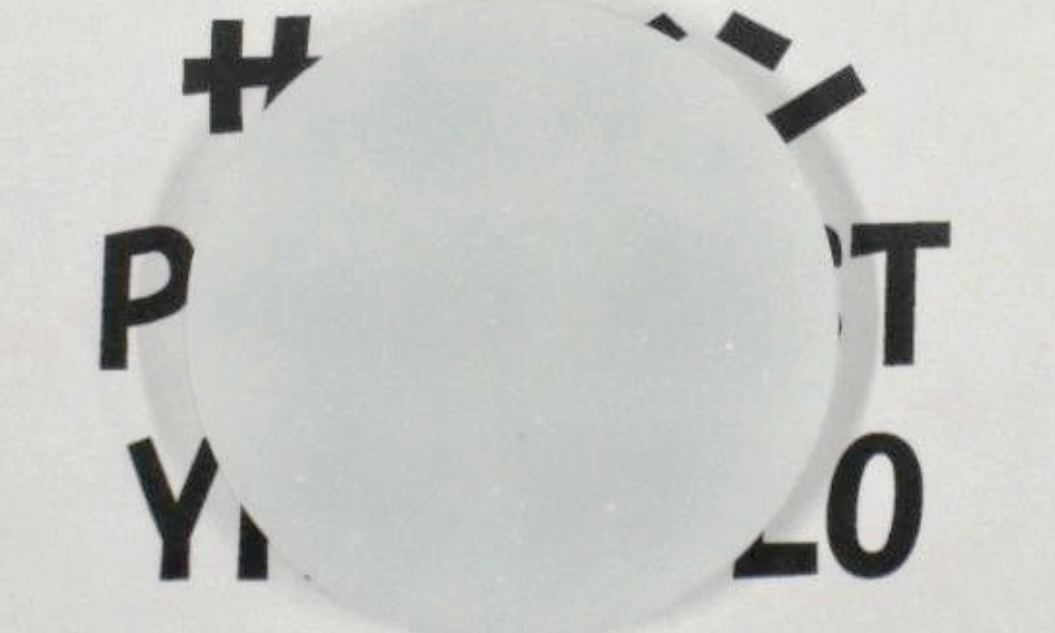

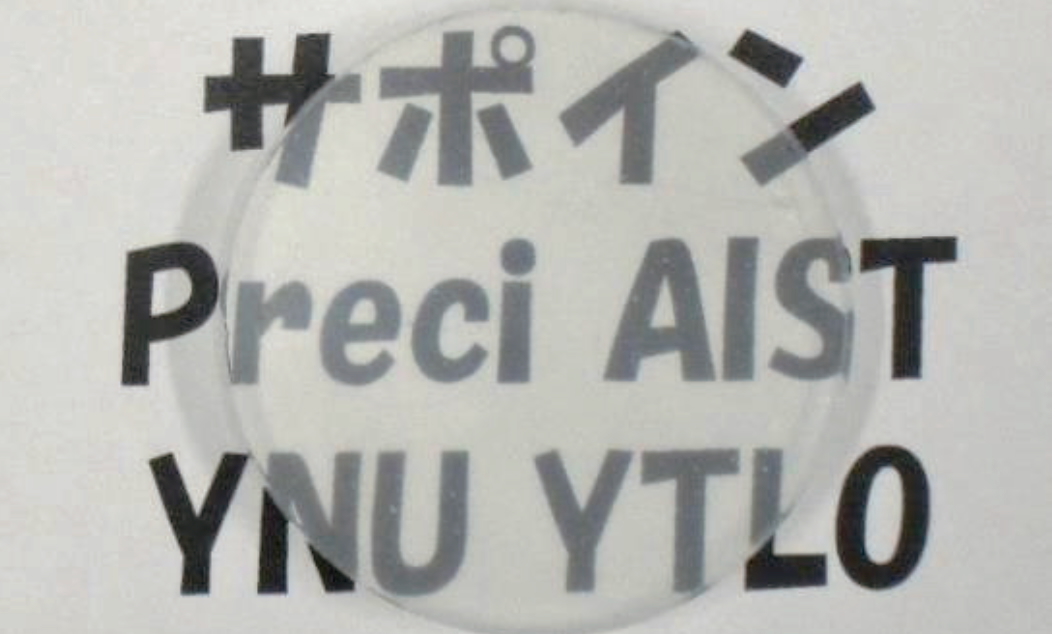

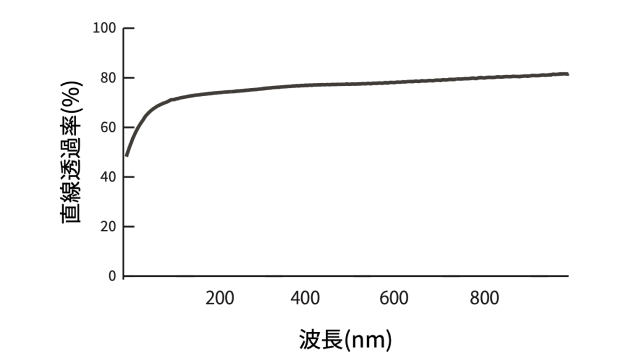

2. Comparison of the translucency of sintered silica (SiO2) bodies

Silica granules produced by spray drying and freeze granulation were molded using a dry press and sintered, and their linear transmittance was evaluated.

Spray drying

Freeze granulation

Linear transmittance

Freeze granulation granules are homogeneous, which means that the sintered body has fewer pore defects that cause light scattering and reduce transmittance, resulting in a difference in translucency.

Summary

Since our development of a large scale freeze granulator in 2019, the advantages of freeze-granulated granules in fine ceramics have become clear. The fine ceramics manufacturing process using freeze granulation has the potential to achieve properties at a level that could not be achieved by spray drying. Meanwhile, as introduced in Slurry Formulation and Spray Drying in Fine Ceramics, it is also possible to obtain high-density sintered bodies with low porosity in spray drying by precisely understanding the shape, size, density, and internal structure of the granules and appropriately controlling the slurry preparation and spray drying conditions. We will continue to conduct research and development aimed at further technological advancements both in spray drying and freeze granulation processes, and contribute to the development of the fine ceramics industry.

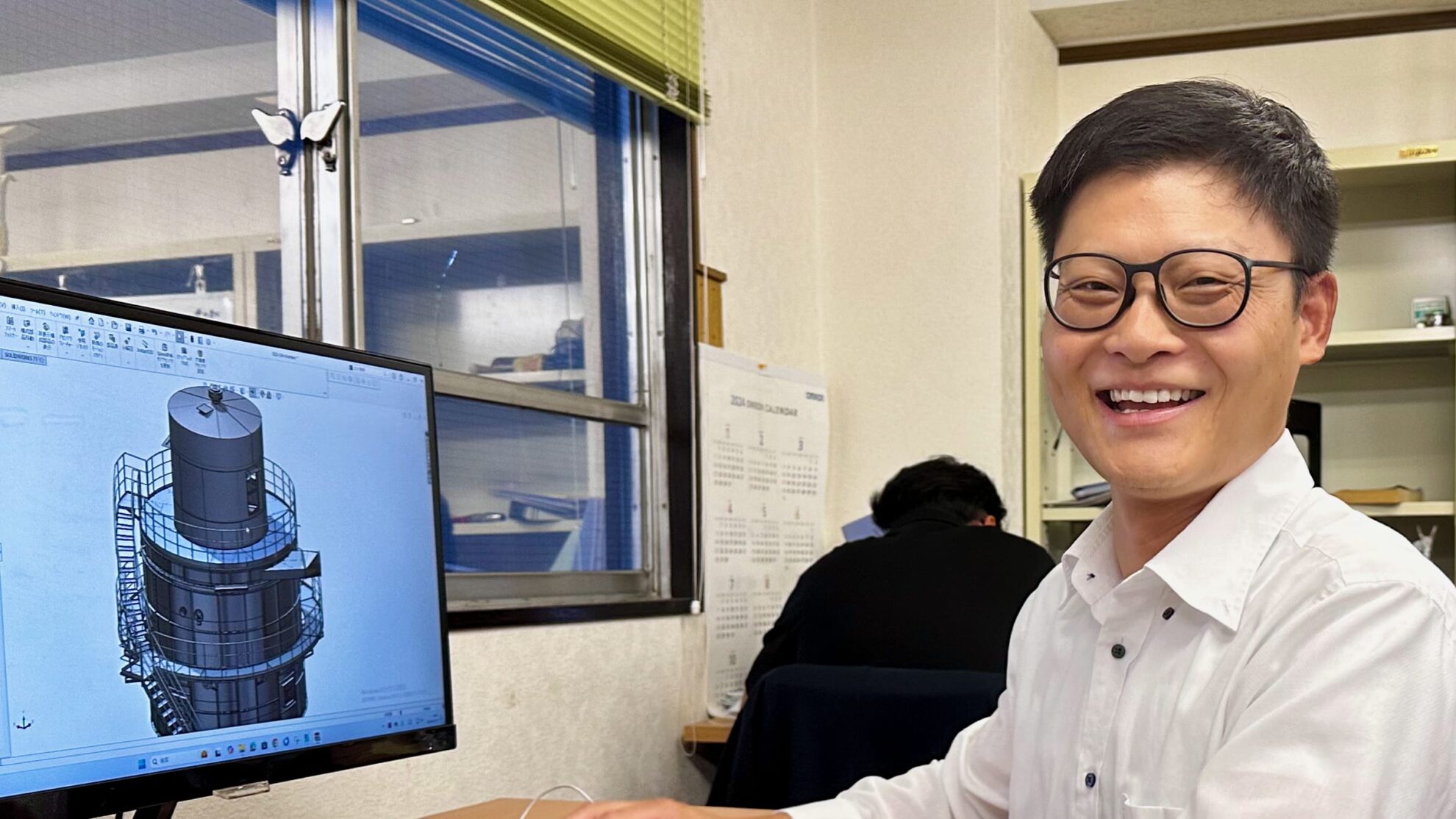

Our spray dryers have a proven track record in the drying and granulation process of fine ceramics. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation” and “Dispersibility of Nanofibers – Freeze Granulation of Cellulose Nanofibers (CNF) and Carbon Nanotubes (CNT)“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.