Powdering live bacteria for probiotics requires advanced process technologies. During the powder manufacturing process, it is necessary to maintain a high viability rate without killing the bacteria, while ensuring highly efficient and stable production. The most widely used manufacturing processes for powdering live bacteria are spray drying and grinding freeze-dried products. Our spray dryers have a proven track record in the spray drying process of live bacterial liquid materials including lactic acid bacteria and bifidobacteria. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations (Probiotics – Spray Drying of Lactic Acid Bacteria and Bifidobacteria). We also have a newly developed powder manufacturing process called freeze granulation. Freeze granulation is a process that produces frozen granules by atomizing a liquid material into an ultra-low temperature environment. The atomized droplets instantaneously get frozen and dried granules are obtained after sublimation process (freeze drying). In 2019, we developed the world’s first production scale dry cooling freeze granulation process.

The dried granules obtained by freeze granulation are spherical in shape, have excellent fluidity, and can maintain low density and high homogeneity. The particle size range of the granules is relatively wide, ranging from 10 to 500 µm, and the tap density equivalent to or higher than spray dried powder can be obtained. Additionally, unlike high-temperature hot gas drying processes, there is no heat effect on materials, and oxidation can be minimized.

Because freeze granulation is a new manufacturing process, there are not many application examples at this moment. However, by using a freeze granulator, it is possible to expect an improvement in the quality of products currently produced with spray dryers. Compared to spray drying, there is no heat impact and it is possible to produce low-density, uniform solid granules.

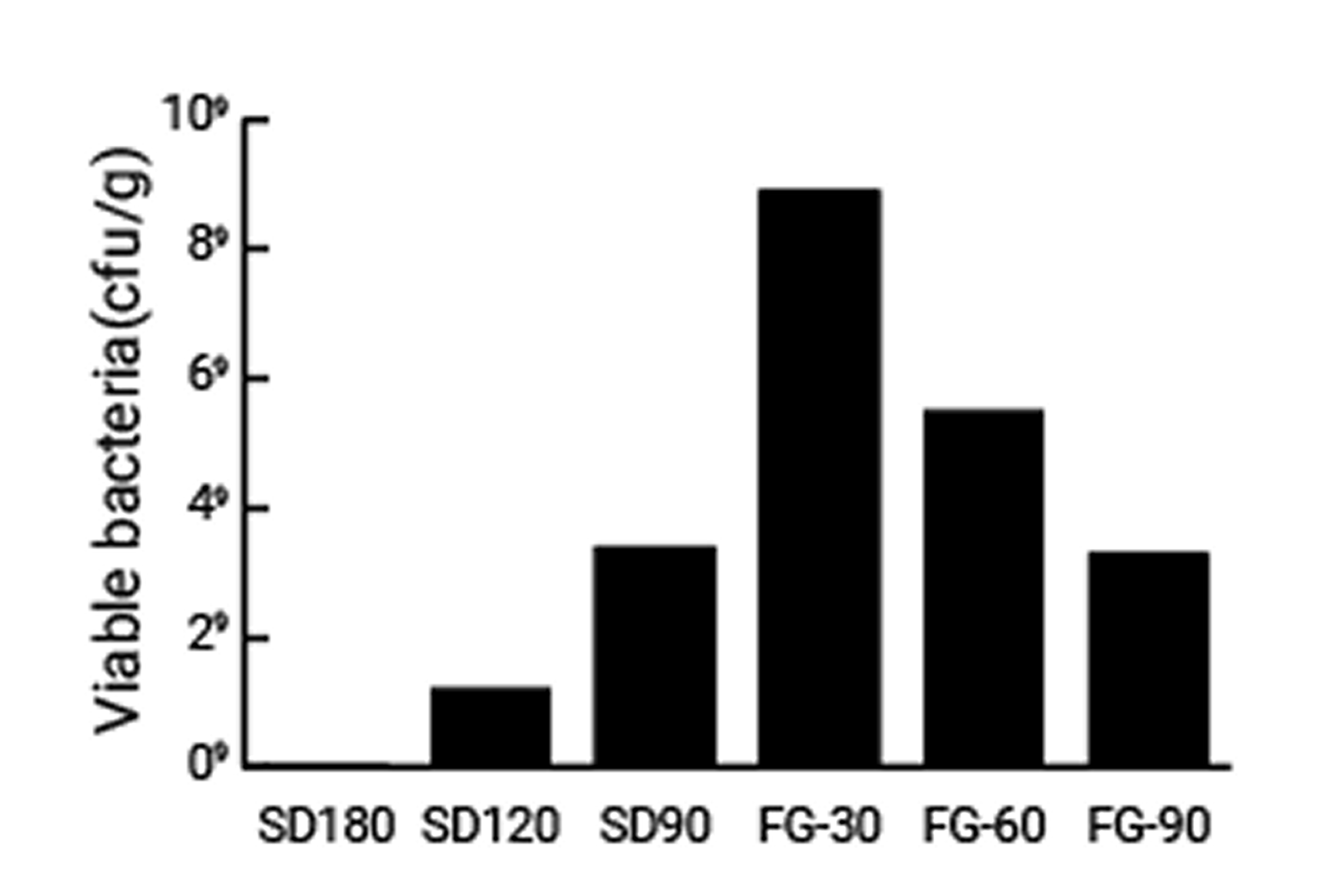

Below are the results of our previous experiment comparing the viability of lactic acid bacteria. We evaluated fermented milk powders produced under multiple temperature conditions using spray drying and freeze granulation processes.

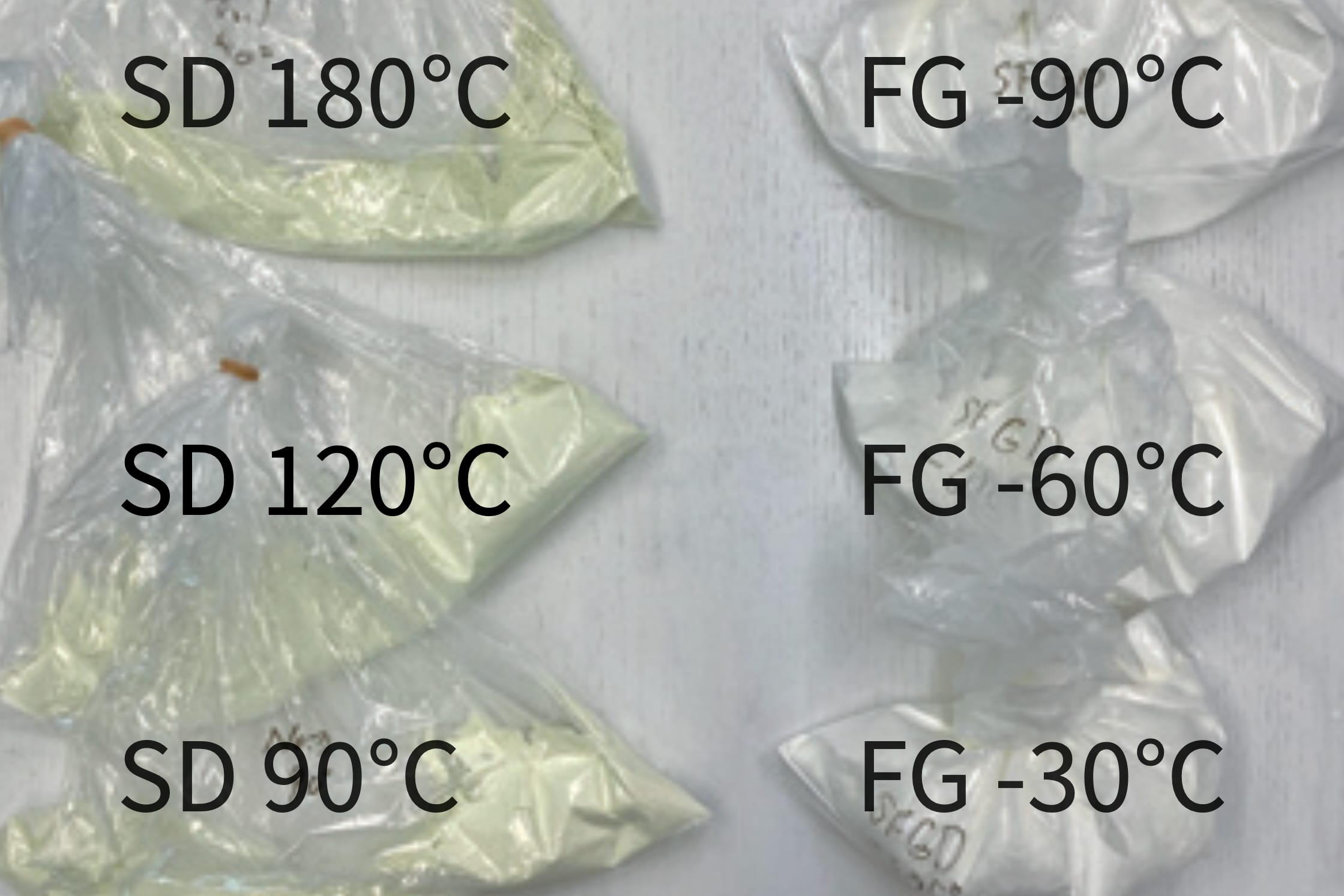

Color comparison

The spray-dried powder turned yellow overall, while the freeze-granulated powder turned white. The higher the temperature, the more yellow the spray-dried powder became, demonstrating the effect of heat.

Viable bacteria count

Evaluation was performed using the MRS agar plate anaerobic culture method. The freeze-granulated powder at -30°C had the highest viable count. It was found that not only are high temperature conditions unfavorable for lactic acid bacteria, but that exposure to temperatures that are too low also reduces viable counts.

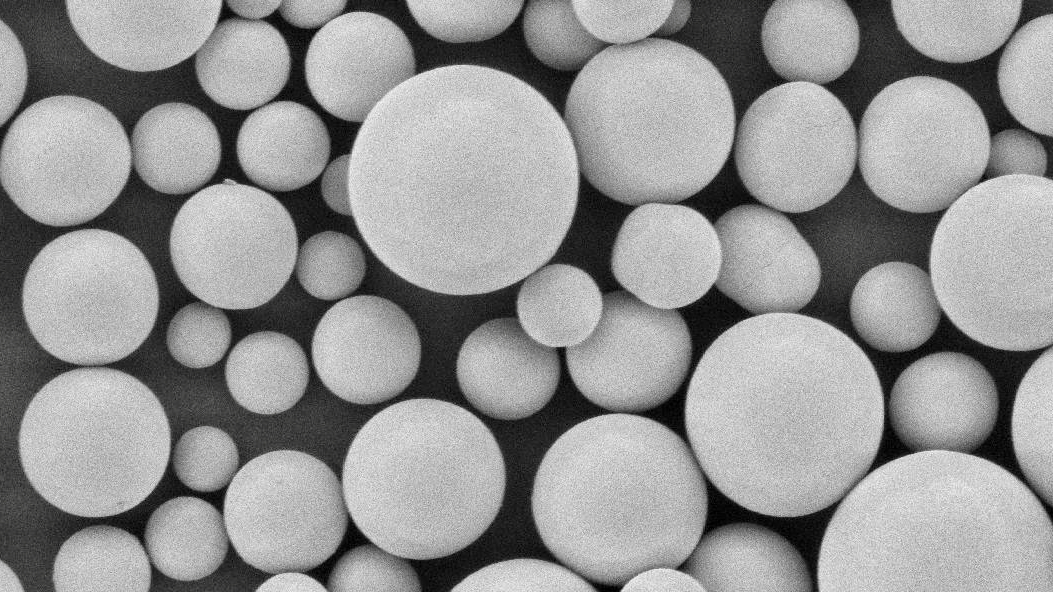

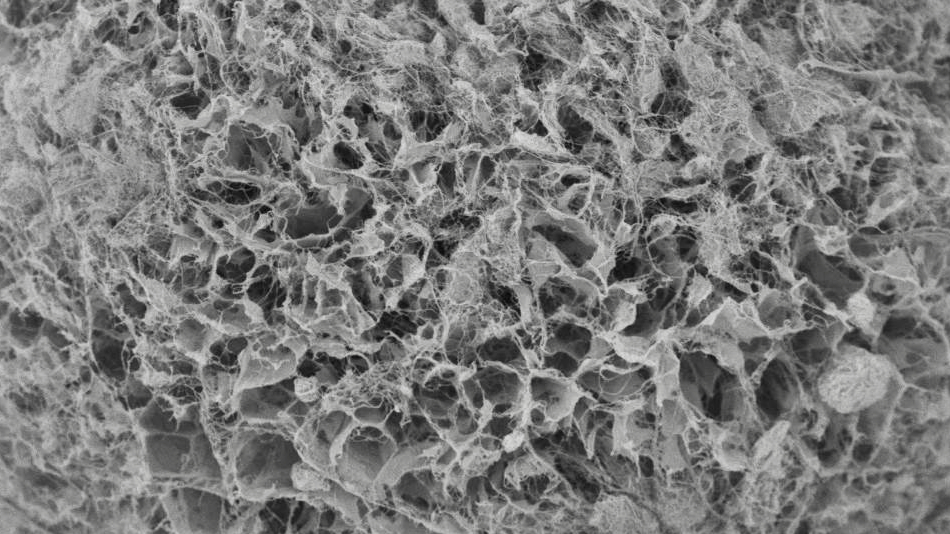

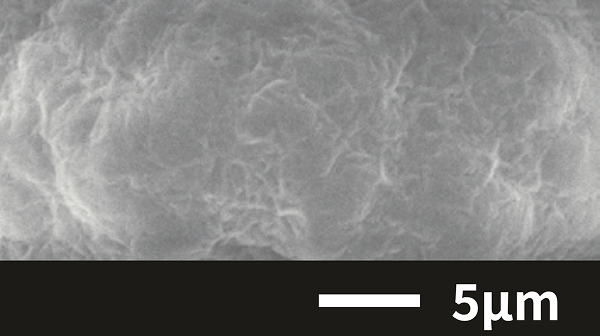

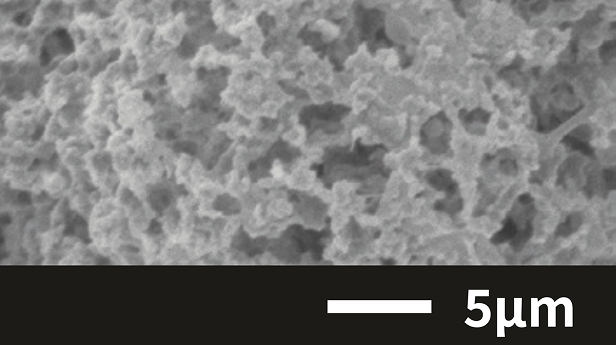

SEM images

SD 120°C

FG -160°C

*We are currently applying for a patent for this result.

Spray-dried powders have no gaps on the surface of the granules and are densely packed. Freeze-granulated powders have many voids on the surface of the granules, resulting in a porous granular structure. Freeze-granulated powders are expected to have advantages in wettability and solubility. To maintain the viability rate while achieving stable, highly efficient production, it is necessary to design an appropriate process that takes into consideration the raw materials, operating conditions, and the quality of the final powder product. The main parameters for quality control of powder products are particle size distribution, bulk density, and moisture content. In addition, particle surface properties related to flowability, wettability, solubility, color, and taste may also be considered.

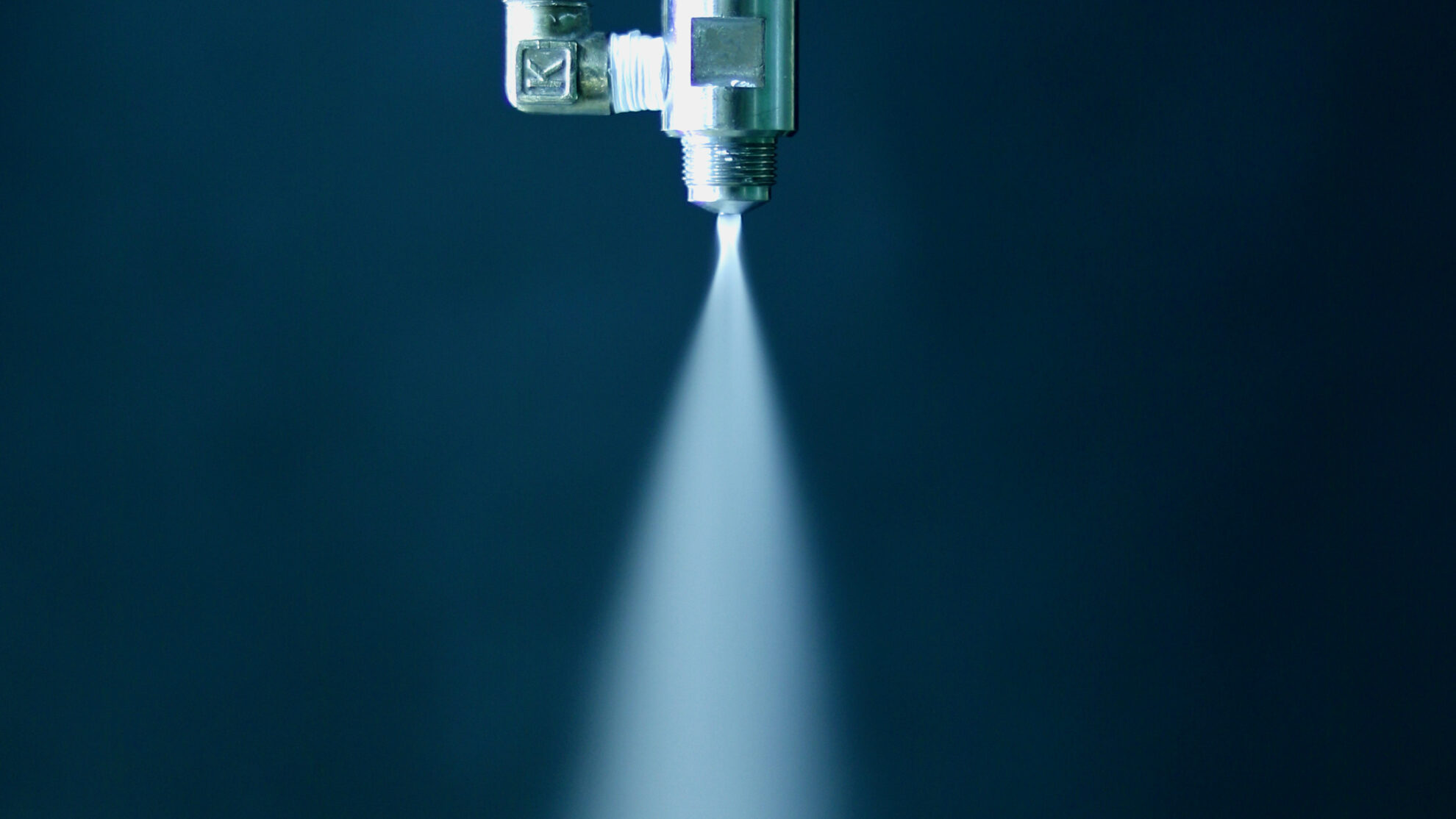

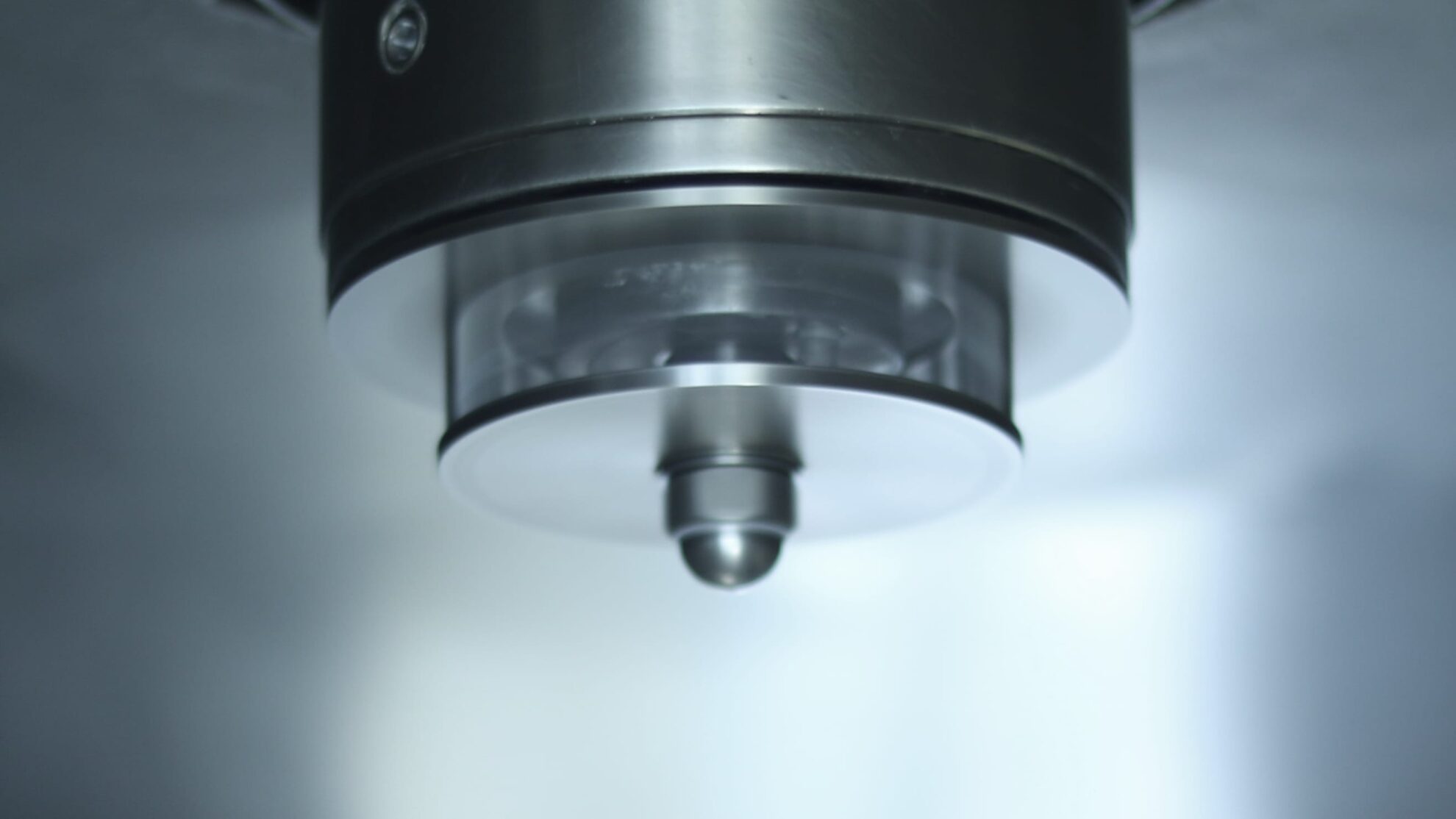

For our latest freeze granulator CS220, Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles just like with spray dryers. When selecting the atomization method, not only the atomized droplet size but also the effects of physical contact and friction must be taken into consideration.

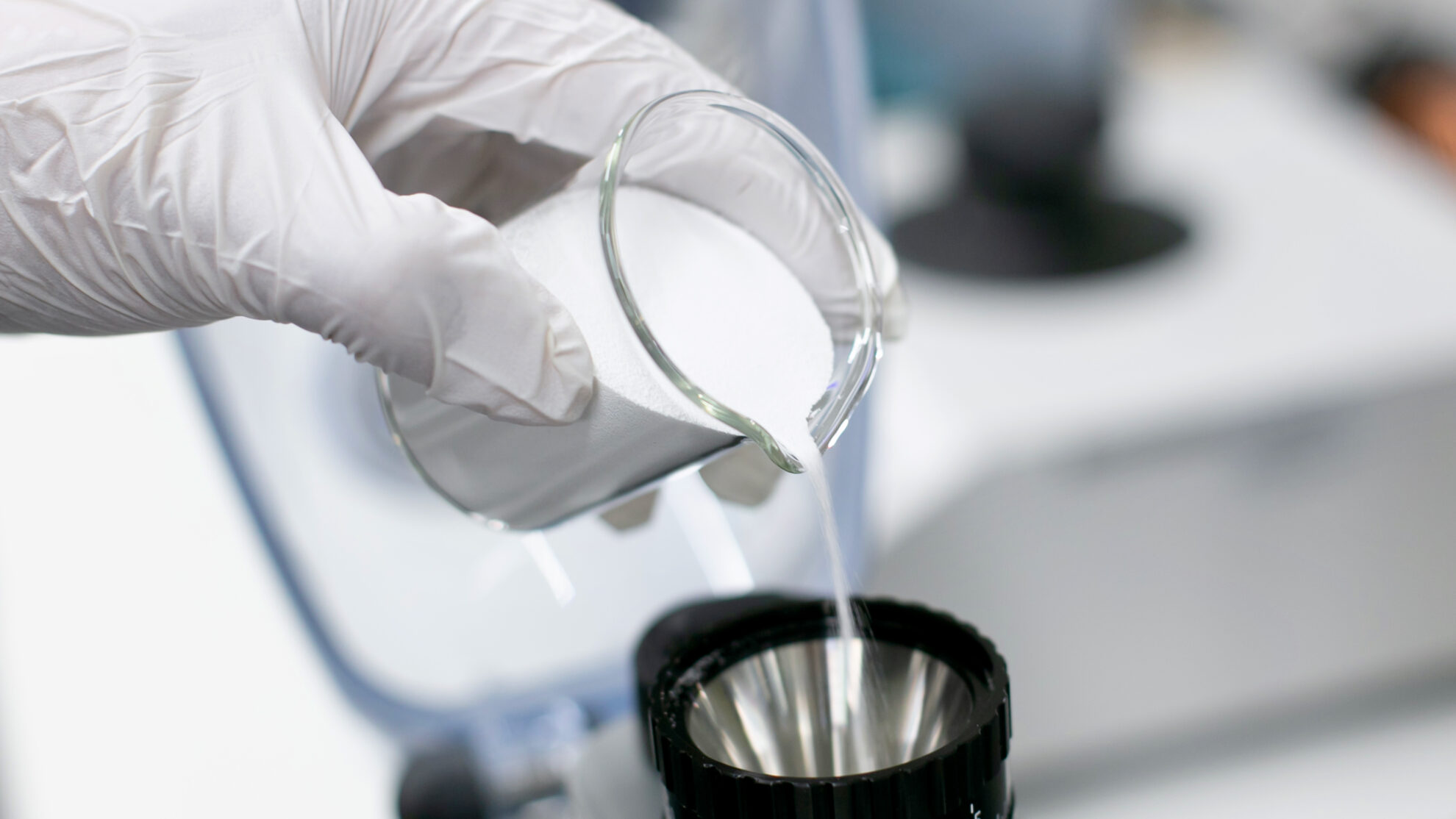

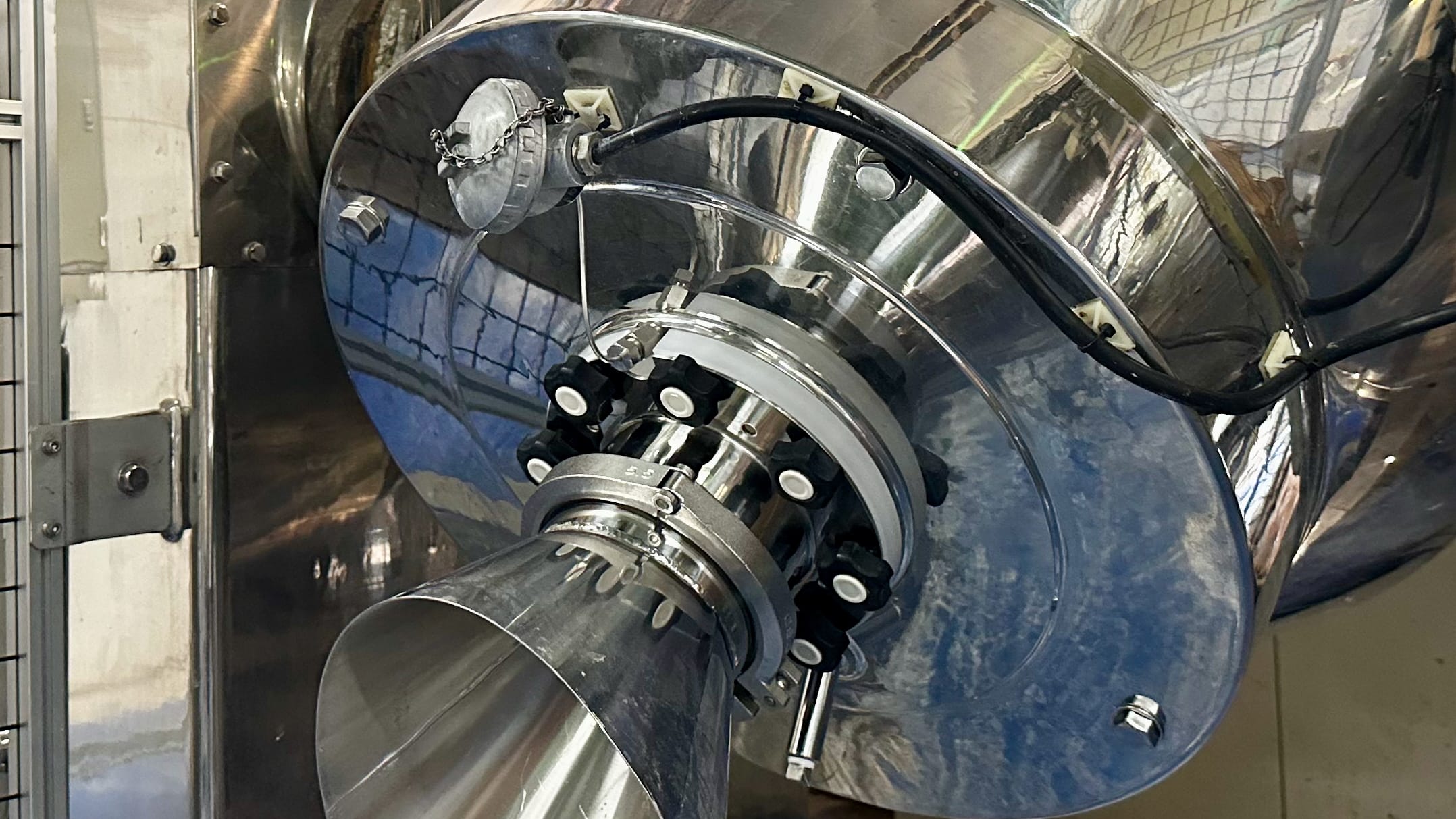

The collected frozen granules are freeze-dried using a rotating freeze dryer. The rotating chamber dries frozen granules uniformly with high efficiency. Drying time can be reduced by over 50% when compared to standard freeze dryers. Powder collection and cleaning are easy thanks to the simple structure. Capacity can be scaled up from 160 to 1,000L. By connecting multiple freeze dryers to CS220 or CS30 and automatically switching connections, it is possible to process as semi-continuous production.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.