There are two major methods for producing dry powders for food, beverages, and pharmaceuticals: drying processes that use heat, such as spray dryers, and drying processes that sublimate the moisture content of frozen materials, such as freeze dryers. In addition to spray dryers, there are various other drying processes that use heat, such as fluidized bed dryers, rotary dryers, and drum dryers. These drying processes are broadly divided into continuous and batch types. Freeze drying process includes general-purpose shelf-type freeze dryers and freeze dryers that operate under vacuum using drums or barrels. Freeze drying process is a batch type process.

Powdered beverages that are consumed by dissolving them in cold or hot water, such as instant coffee and instant tea (green tea, oolong tea, roasted green tea, flavored tea, etc.), are mainly produced using spray dryers or freeze dryers. Spray drying is a continuous process, which allows for low manufacturing costs, but is said to result in inferior flavor due to heat effects. Freeze drying is a batch process, making it less productive and consuming more energy, which increases manufacturing costs. Freeze-dried products are said to have better flavor than spray-dried products due to the reduced heat effects.

The quality difference due to heat affects not only the flavor but also the color. It is said that spray-dried products such as powdered milk, powdered creamer, powdered seasonings, and powdered supplements are prone to discoloration due to heat. This can occur if the spray dryer is not operated properly or if the product is left piled up during the drying process, resulting in prolonged exposure to high temperatures. This situation may cause the product to turn yellow and result in color variations between production lots.

In the drying process of live bacteria for food and pharmaceutical products, it is necessary to maintain a high viability rate. Freeze drying process also poses challenges in terms of viability. During the freezing process, it takes a long time for the temperature to reach the freezing point after the raw materials are loaded, and the bacteria can be damaged by metabolic products produced during the time, resulting in a decrease in viability. Furthermore, during freezing, differences in specific gravity of the materials may cause segregation of the raw materials, resulting in loss of homogeneity. Grinding and mixing processes that are carried out after freeze drying can also physically damage the product.

In spray drying, it is important to lower the process gas temperature as much as possible while taking productivity into consideration in order to minimize the thermal impact on the product. In addition, reducing the particle size can sometimes shorten the drying time. The larger the surface area per unit volume of the droplets, the more efficiently they come into contact with the drying gas, reducing the product’s residence time in the process.

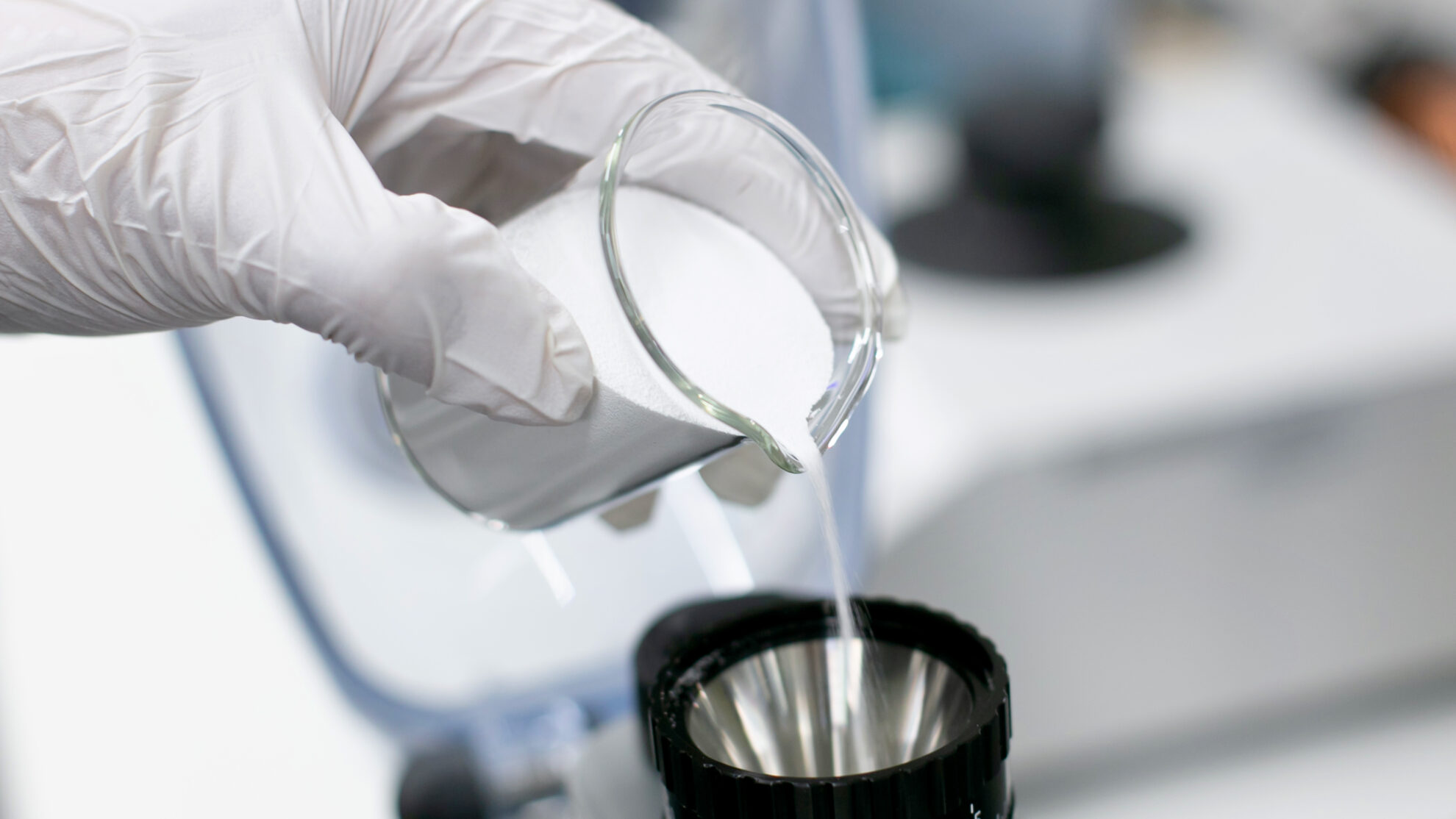

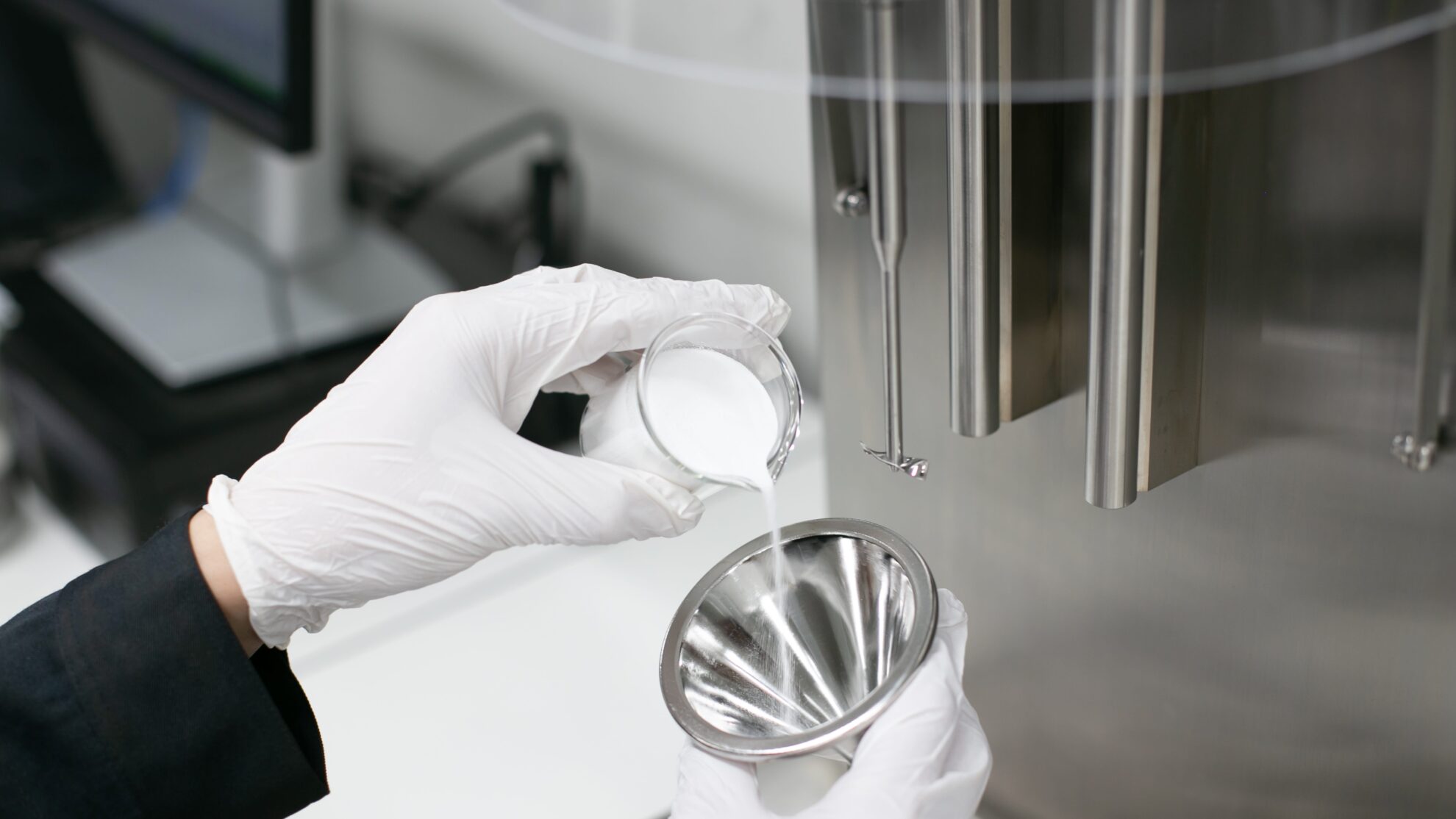

Freeze granulation is a process that produces frozen granules by atomizing a liquid material into an ultra-low temperature environment. The atomized droplets instantaneously get frozen and dried granules are obtained after sublimation process (freeze drying). In 2019, we developed the world’s first production scale dry cooling freeze granulation process.

Freeze granulation can solve various problems that arise when performing grinding and mixing after freeze drying, as well as the heat effect of spray drying.

Continuously produces uniform spherical granules with high flowability

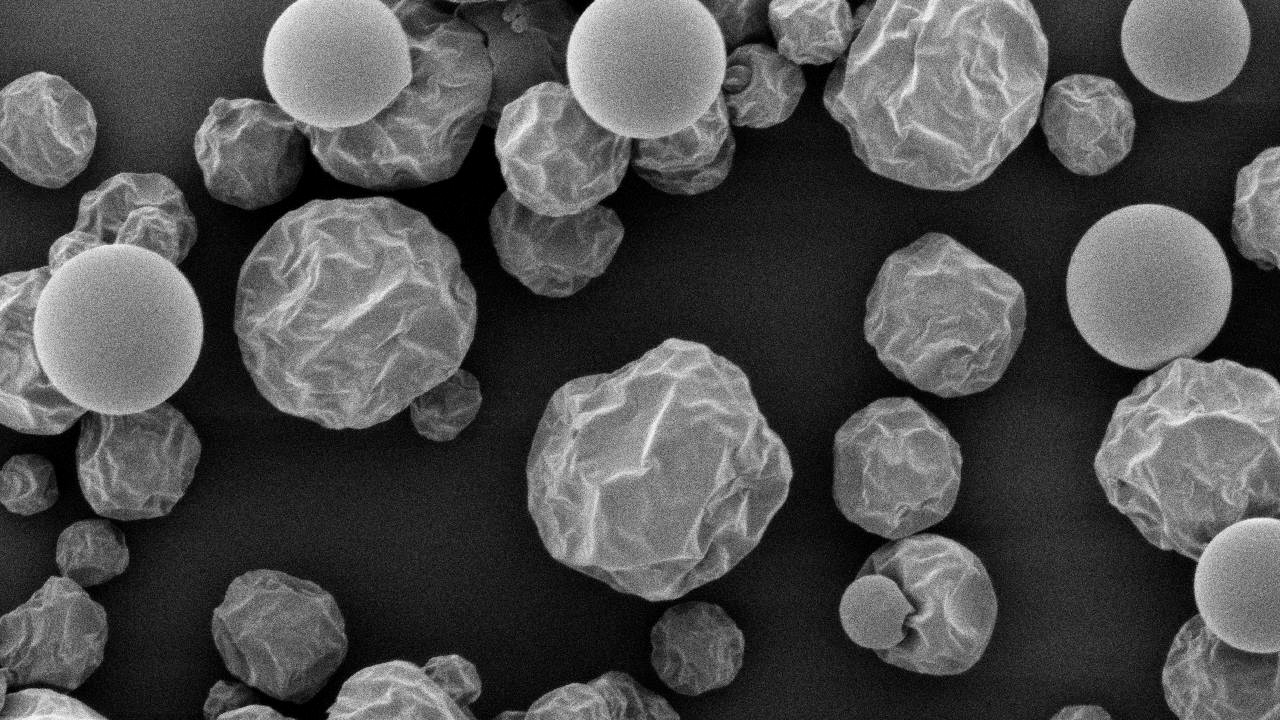

Like spray drying, freeze granulation is a continuous process to create spherical frozen bodies due to the surface tension acting on the atomized droplets of a liquid material. The shape of the droplets can be maintained even during the subsequent freeze drying process, resulting in powder with excellent fluidity. In terms of grinded and mixed freeze-dried products, the powder becomes irregularly shaped particles due to the grinding process. Furthermore, physical damage caused by friction during grinding can degrade the quality. Additionally, freeze drying, grinding, and mixing are all batch processes, which increases the number of manufacturing steps, increasing both the initial investment cost and manufacturing costs.

Homogeneous with no segregation

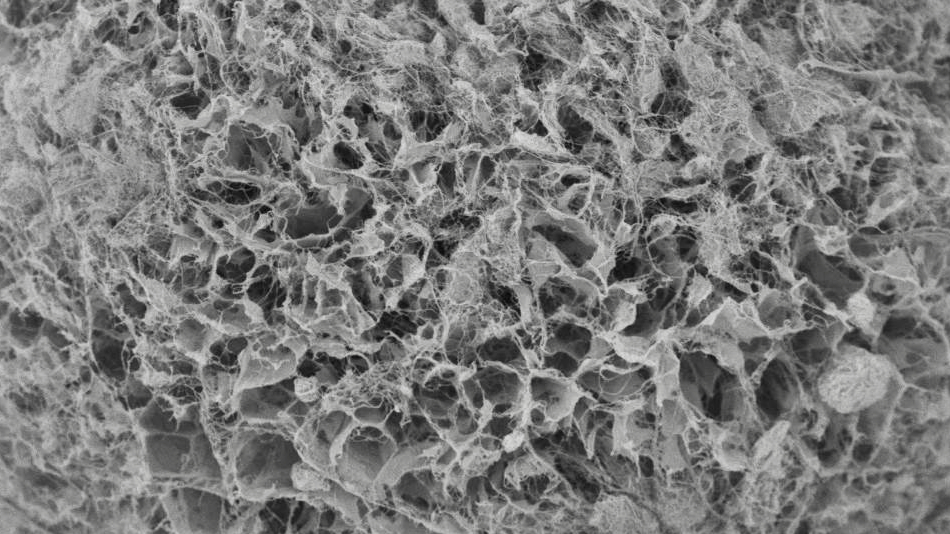

The major difference between freeze granulation and the grinding process of freeze-dried products is the freezing speed. When pre-freezing in a freezer, the freezing process takes several hours, so segregation of ingredients occurs during the freezing process. In addition, if the material is a suspension, segregation due to sedimentation may be a problem. On the other hand, in freeze granulation, specific surface area of atomized droplets increases, resulting in instant freezing and the granular structure is immobilized without segregation. Even in the subsequent freeze-drying process, the moisture sublimes with almost zero material movement and shrinkage so that the dried powder can maintain a homogeneous and structured state.

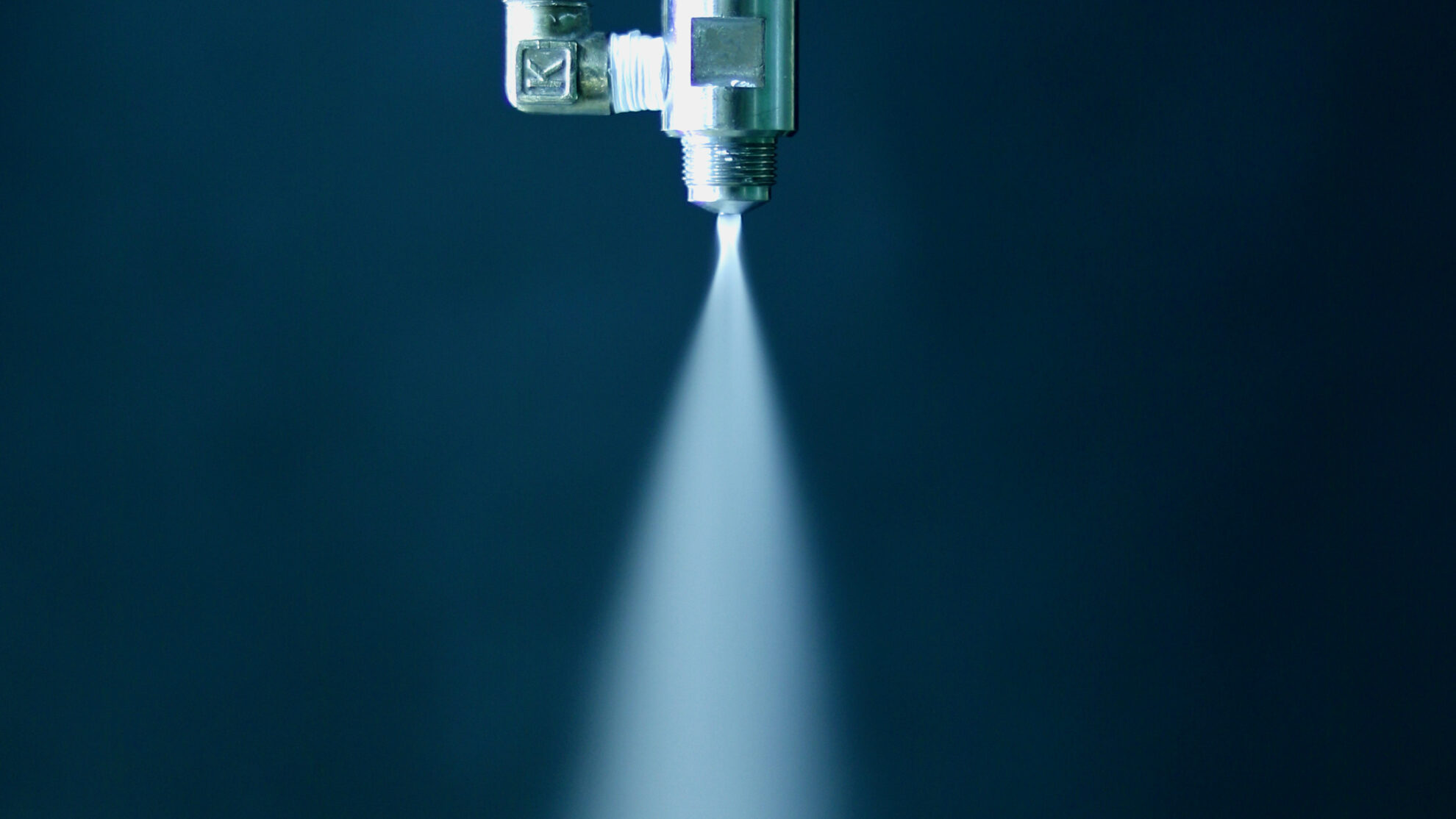

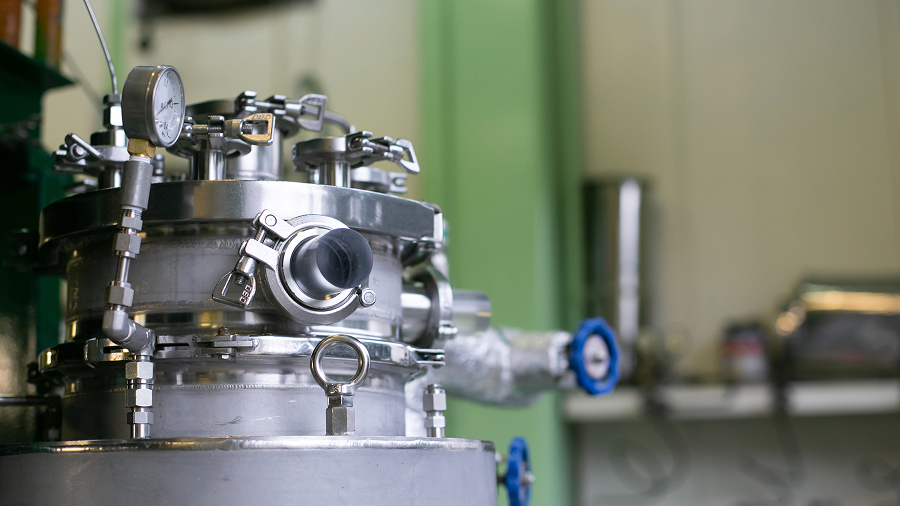

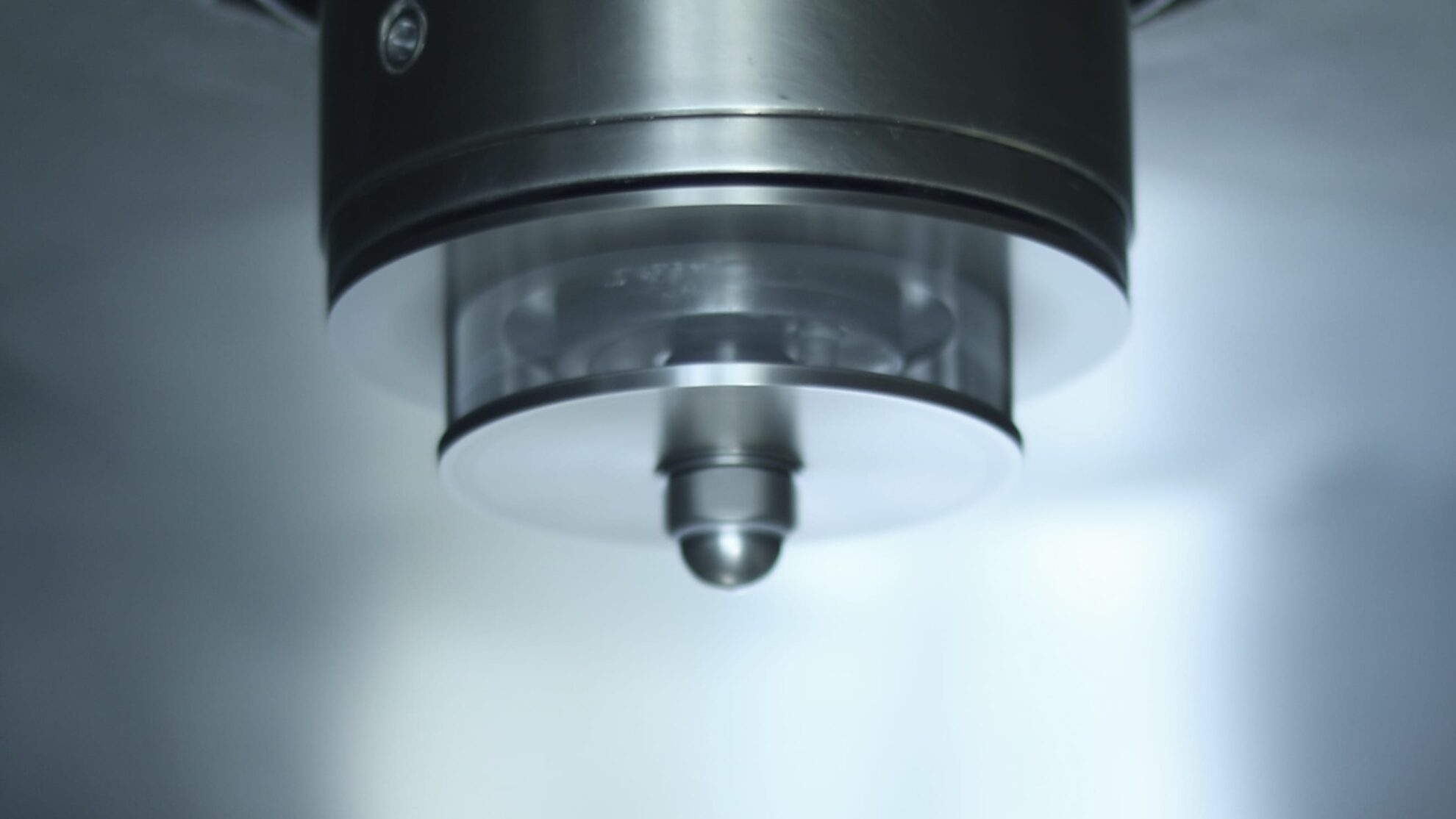

The dried granules obtained by freeze granulation are spherical in shape, have excellent fluidity, and can maintain low density and high homogeneity. The particle size range of the granules is relatively wide, ranging from 10 to 500 µm, and the tap density equivalent to or higher than spray dried powder can be obtained. Additionally, unlike high-temperature hot gas drying processes, there is no heat effect on materials, and oxidation can be minimized. For our latest freeze granulator CS220, Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles just like with spray dryers. When selecting the atomization method, not only the atomized droplet size but also the effects of physical contact and friction must be taken into consideration.

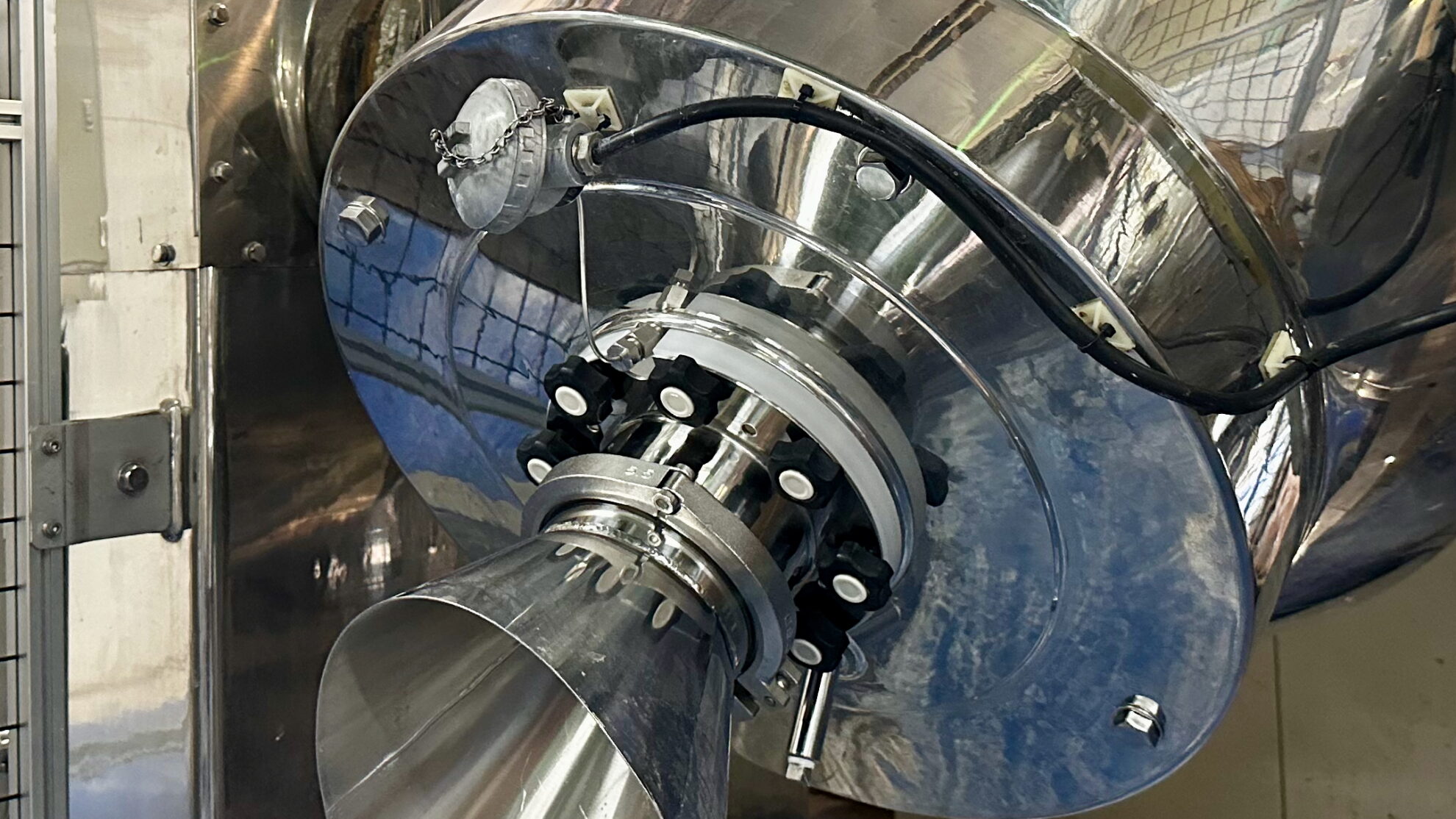

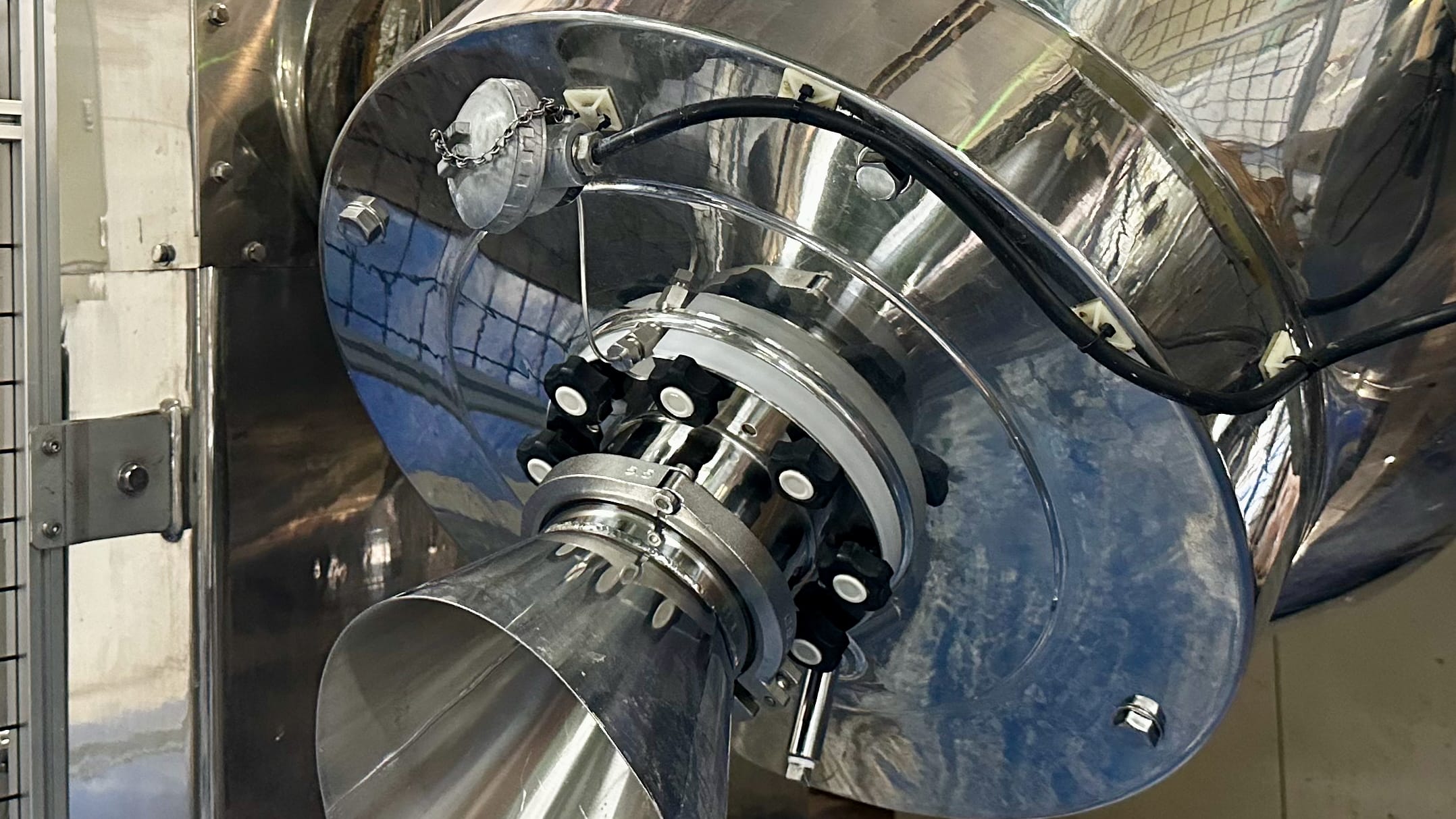

The collected frozen granules are freeze-dried using a rotating freeze dryer. The rotating chamber dries frozen granules uniformly with high efficiency. Drying time can be reduced by over 50% when compared to standard freeze dryers. Powder collection and cleaning are easy thanks to the simple structure. Capacity can be scaled up from 160 to 1,000L. By connecting multiple freeze dryers to CS220 or CS30 and automatically switching connections, it is possible to process as semi-continuous production.

Because freeze granulation is a new manufacturing process, there are not many application examples at this moment. However, by using a freeze granulator, it is possible to expect an improvement in the quality of products currently produced with spray dryers. Compared to spray drying, there is no heat impact and it is possible to produce low-density, uniform solid granules.

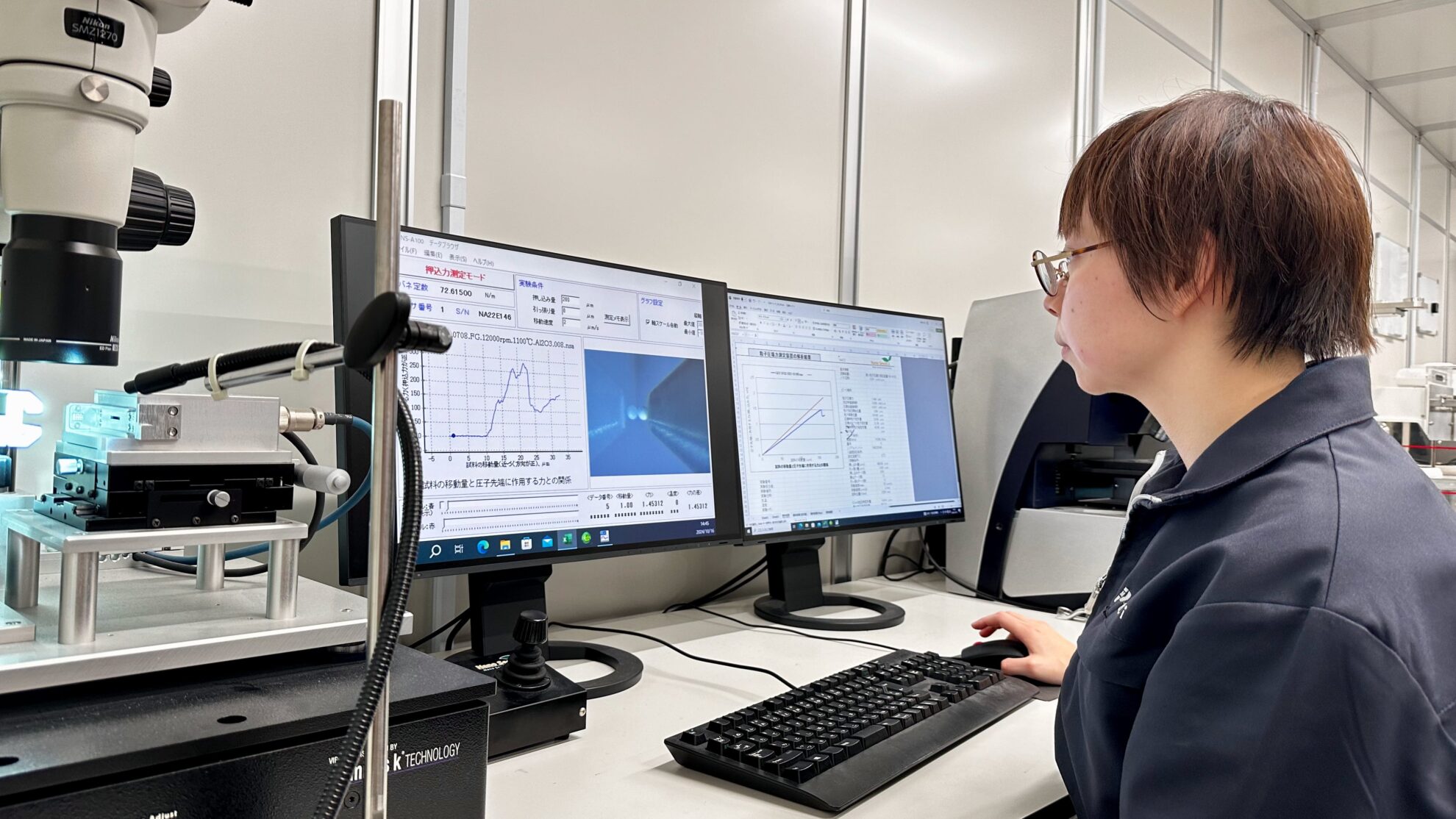

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.