Amorphous (non-crystalline) refers to a disordered solid state in which the periodic arrangement of molecules is lost and no crystalline structure is observed. Amorphous is unstable due to its high energy state, and generally undergoes a transition to a stable crystalline state. In food and pharmaceuticals, amorphous is said to have high solubility and membrane permeability, and is widely used in fields such as drug delivery systems (DDS) to improve bioavailability.

DDS is a technology that aims to enhance the efficacy of medicines and reduce side effects by delivering the right amount of active pharmaceutical ingredients (APIs) to the desired location at the right time. Advances in nanotechnology have made it possible to process materials at the atomic level, leading to advances in technology for encapsulating drugs in carriers and transporting them appropriately to the desired location. The market for DDS using nanotechnology is expected to grow at a rate of 9% per year, reaching US$200 billion in 2032.

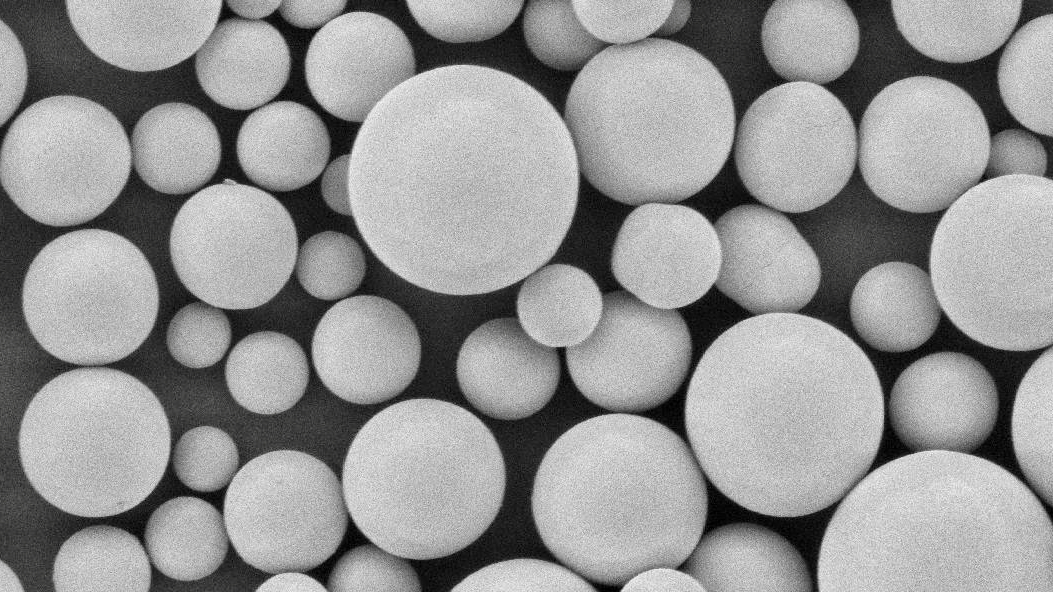

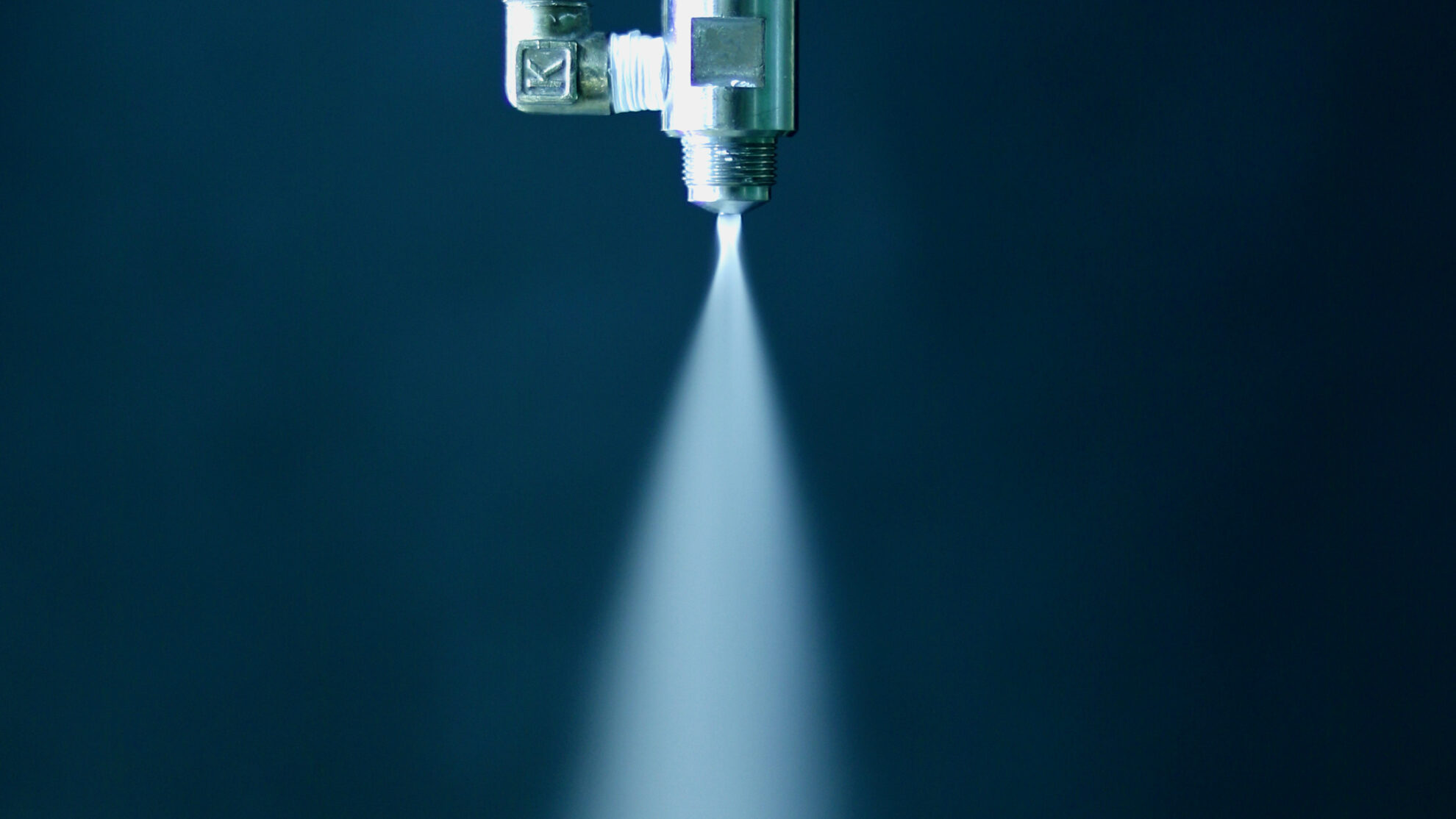

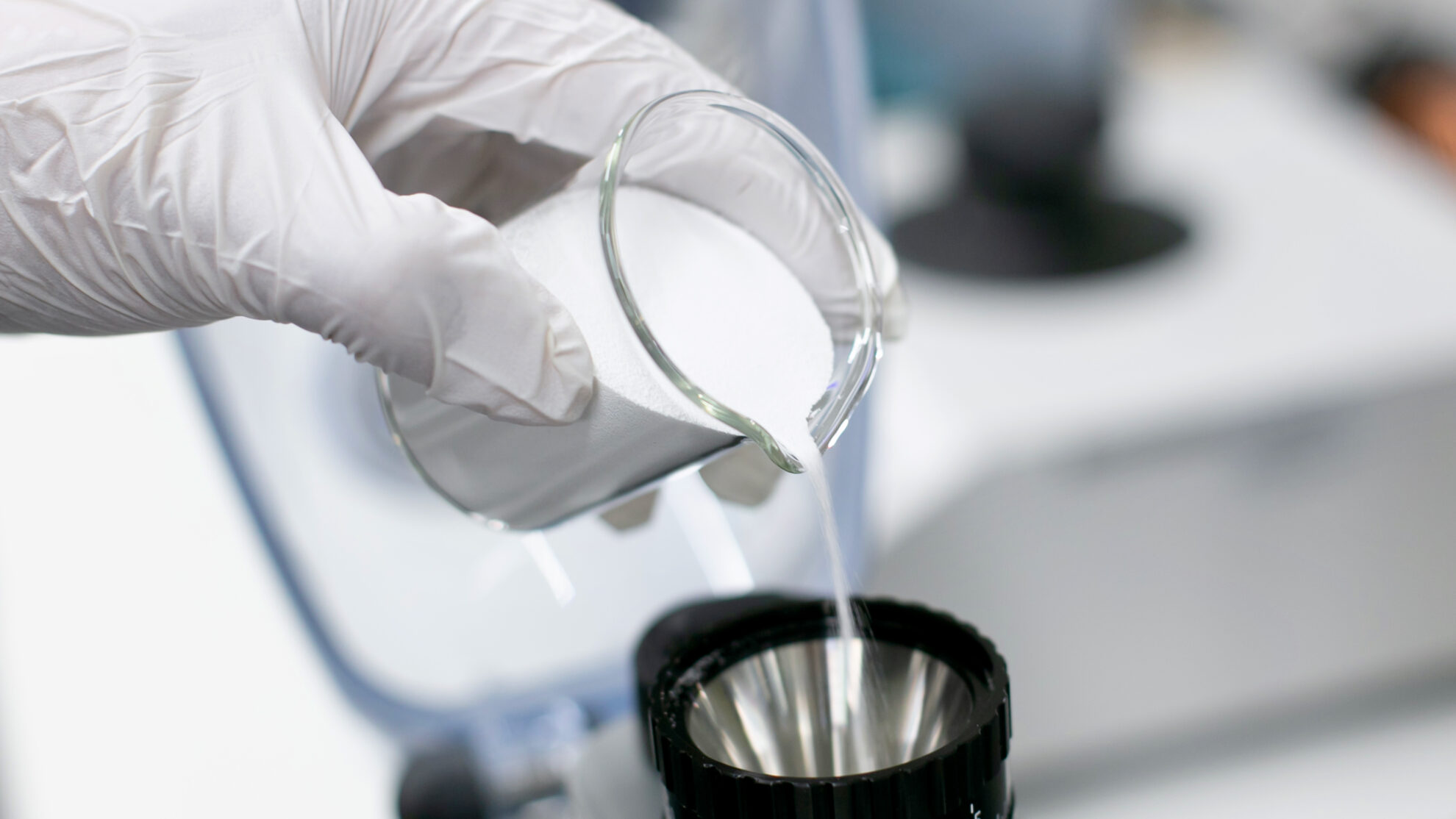

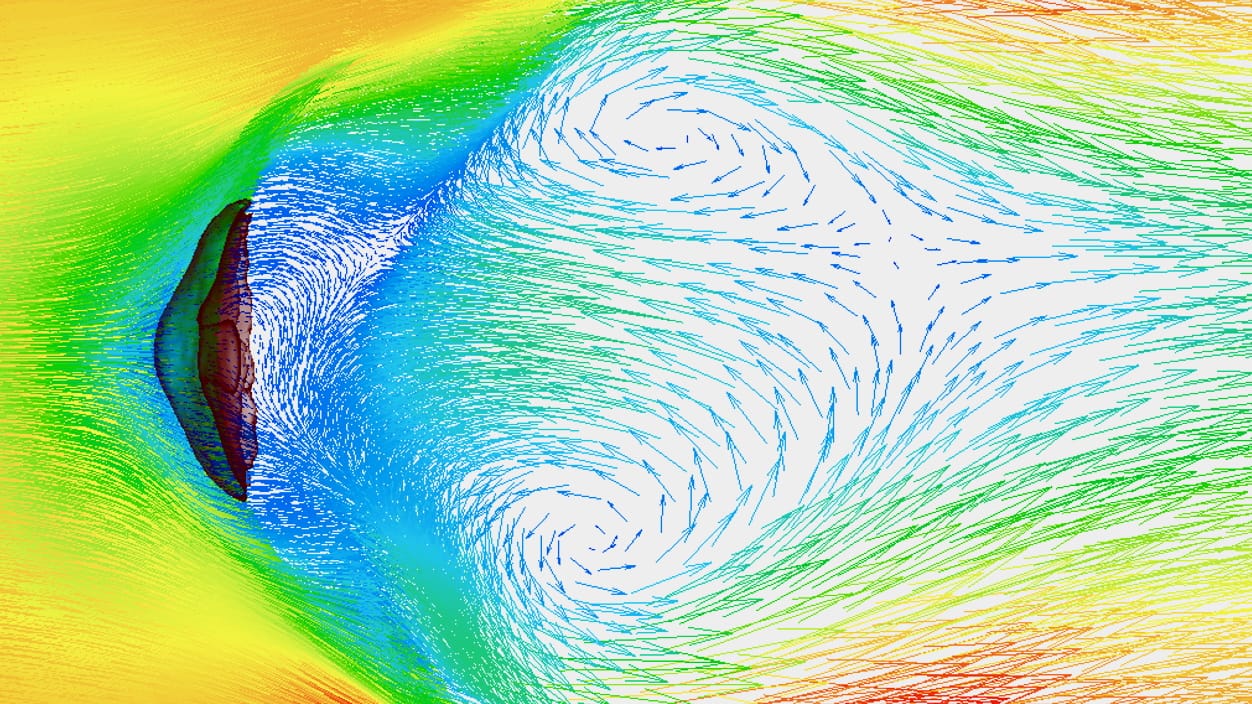

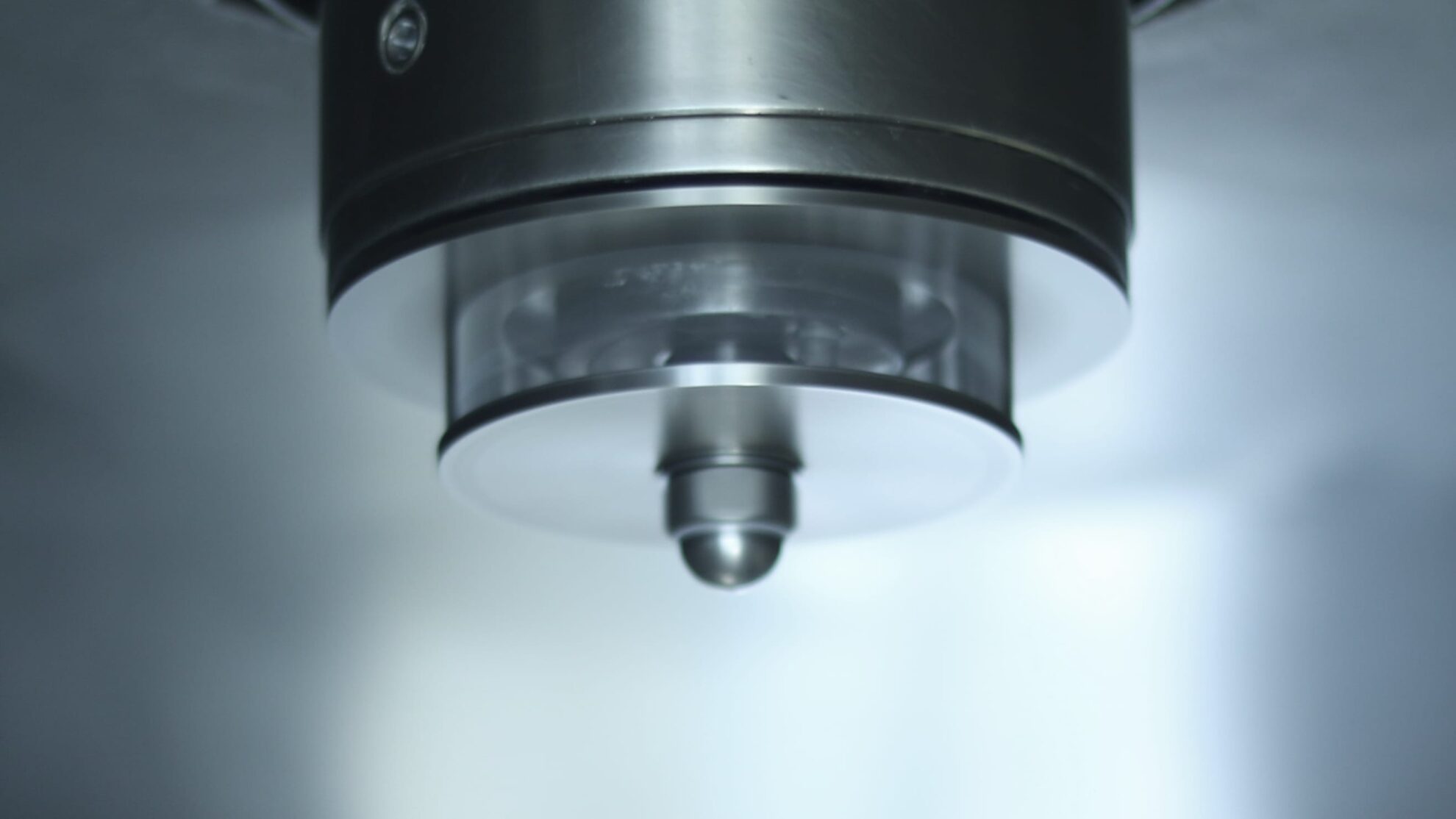

Spray drying is a widely used powder manufacturing process for producing amorphous solid dispersions. By atomizing a liquid material containing dissolved pharmaceuticals and additives into a high-temperature air stream, it is possible to instantly dry the powder and obtain granulated powders. The dried powder obtained by spray drying is spherical and has excellent fluidity, resulting in a sharper and more stable particle size distribution than other drying processes. In addition, closed-cycle spray dryers can also use organic solvents by using nitrogen as a process gas. Since spray dryers have been proven to be scalable, they have a proven track record as a method for manufacturing amorphous complexes (core amorphous), poorly soluble low-molecular-weight substances, active pharmaceutical ingredients (APIs), solid dispersion formulations using water-soluble polymers, dry powder inhalers (DPI), and inactive carrier particles such as lactose.

Core Amorphous is an amorphous formulation that uses low-molecular-weight compounds such as organic salts and amino acids as counter compounds instead of conventional solid dispersions that use water-soluble polymers. By selecting the counter compound, it is possible to control absorption and solubility. In addition, by using a spray dryer, it is possible to precisely control particle shape, density, outer shell surface condition, internal structure, etc.

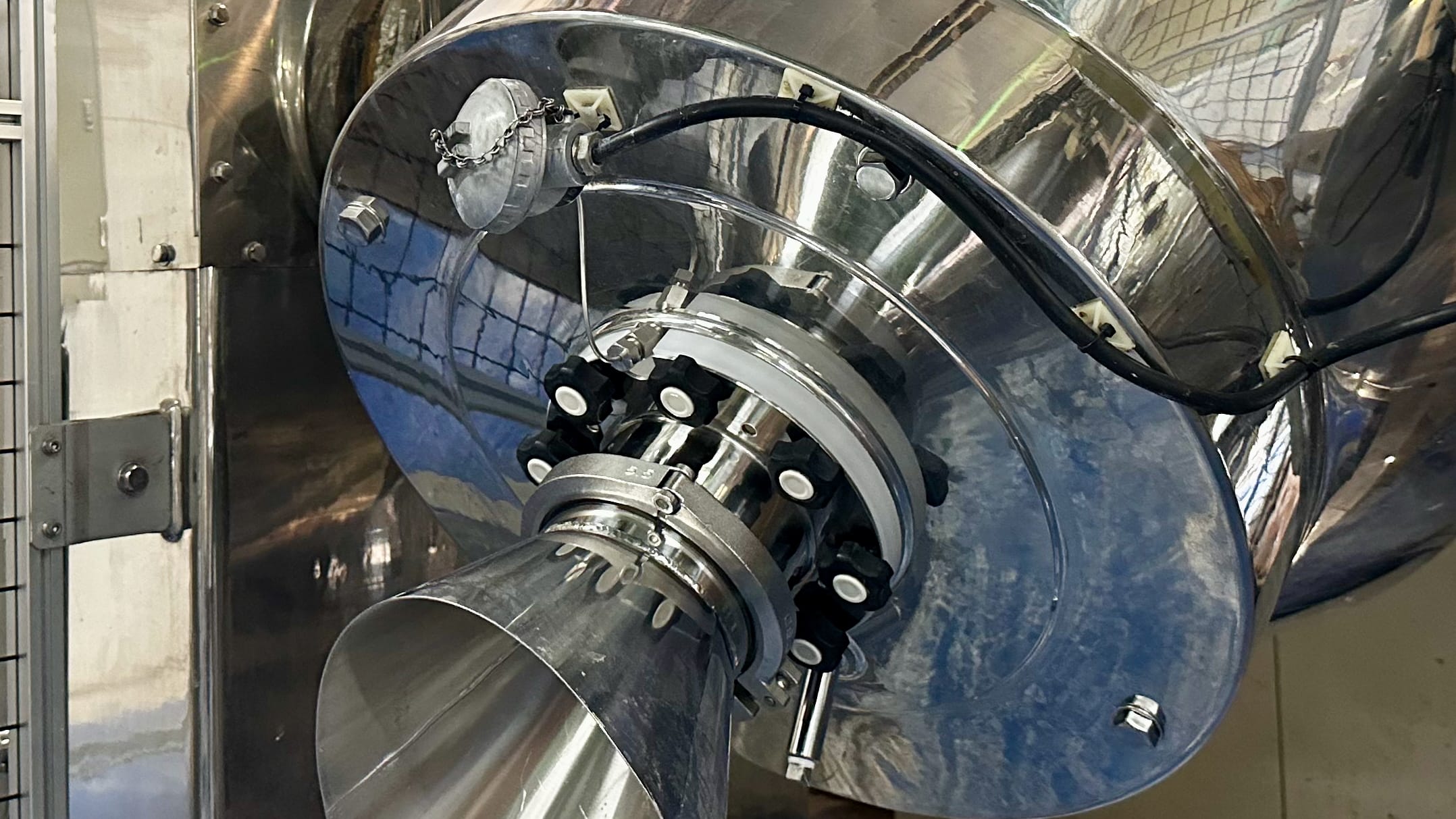

Freeze granulation is a process that produces frozen granules by atomizing a liquid material into an ultra-low temperature environment. The atomized droplets instantaneously get frozen and dried granules are obtained after sublimation process (freeze drying). In 2019, we developed the world’s first production scale dry cooling freeze granulation process. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. Freeze granulation process is a two-step powder manufacturing process consisting of a freezing process in which a liquid material is atomized and rapidly cooled down to obtain frozen granules, and a drying process in which the frozen granules are freeze-dried to obtain dried granules. The freezing process is continuous, while the freeze-drying process is batch-based. In order to eliminate the drawback of the batch-type freeze-drying process which is the latter stage, it is possible to process as semi-continuous production by connecting multiple freeze dryers to the freeze granulator and automatically switching connections between them.

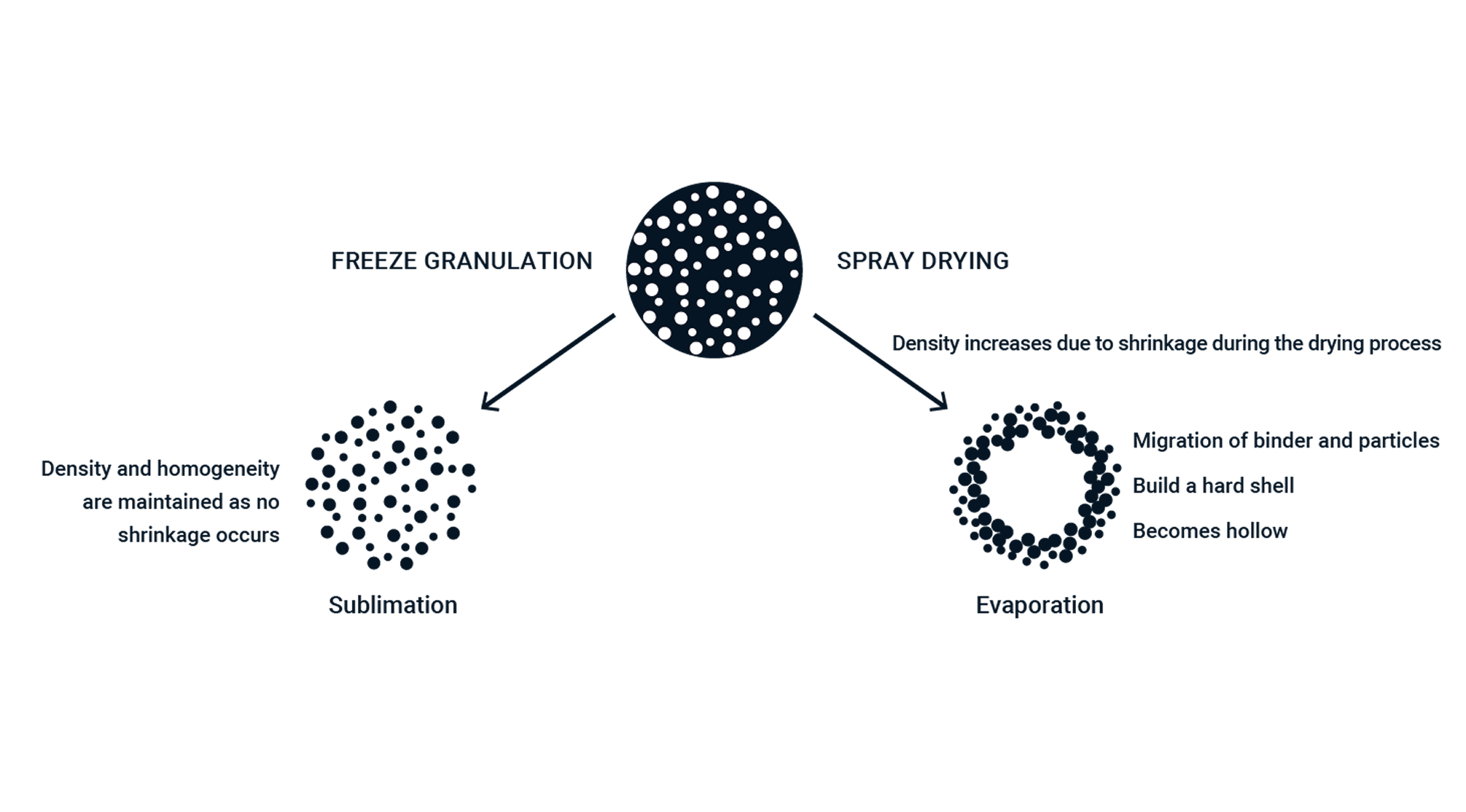

Comparison of spray drying and freeze granulation

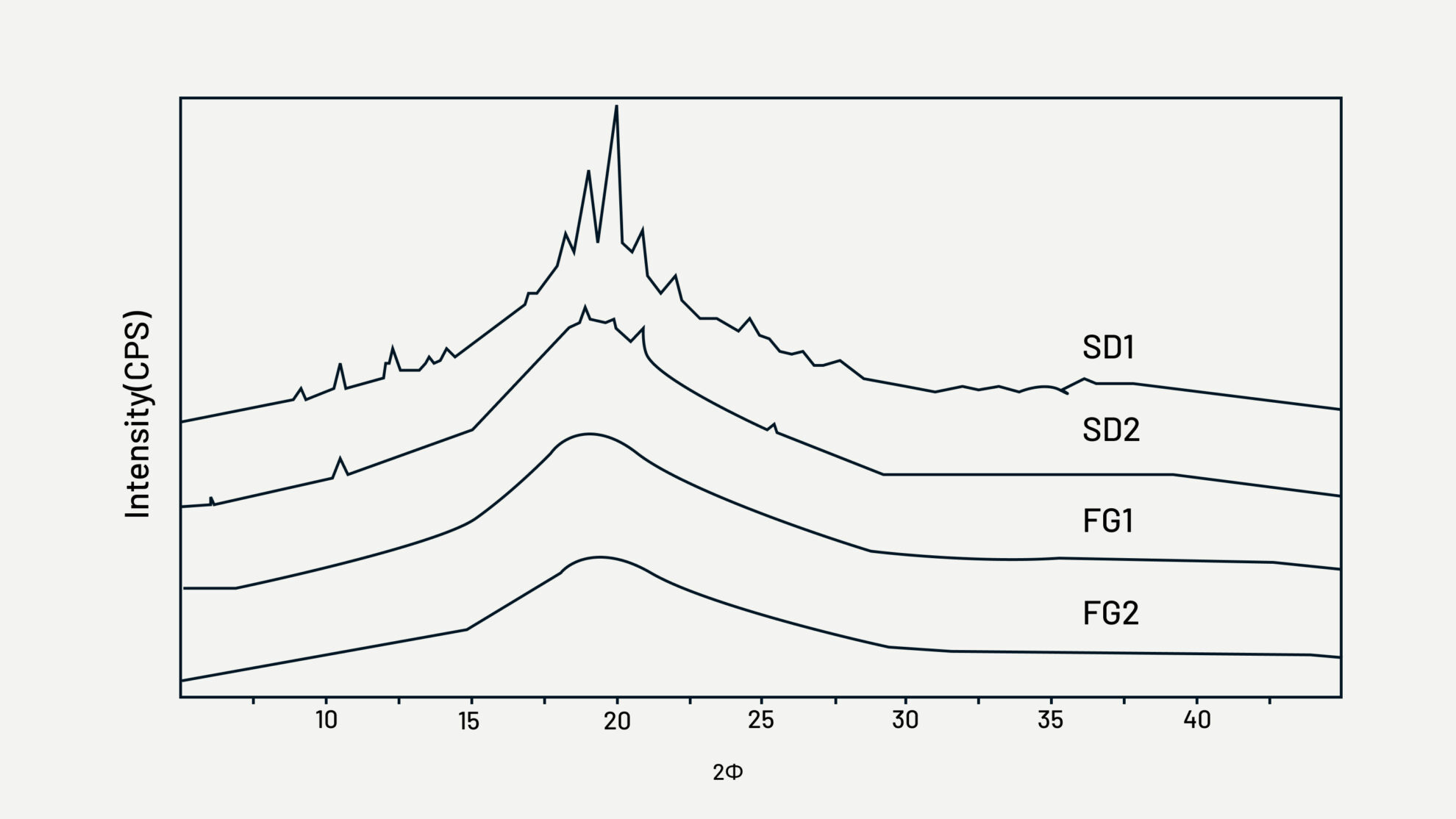

Comparison of the crystal structure of lactose solutions

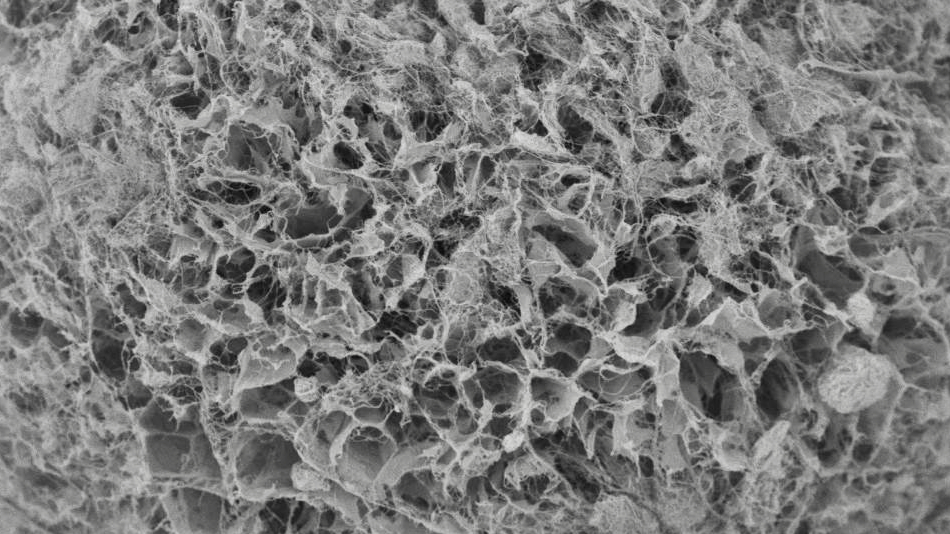

The dried granules obtained by freeze granulation are spherical in shape, have excellent fluidity, and can maintain low density and high homogeneity. The particle size range of the granules is relatively wide, ranging from 10 to 500 µm, and the tap density equivalent to or higher than spray dried powder can be obtained. Additionally, unlike high-temperature hot gas drying processes, there is no heat effect on materials, and oxidation can be minimized. The figure on the upper right shows the results of an experiment we previously conducted on the crystalline structure of lactose solutions. Granules produced by spray drying and freeze granulation were compared using X-ray diffraction. It was confirmed that the spray-dried granules had a certain amount of peaks indicating a crystalline structure, while the freeze-granulated granules were more amorphous. The X-ray diffraction pattern of an amorphous solid is a halo pattern with no peaks. Because it has an unstable metastable crystalline structure, it is superior to stable solids in terms of solubility and dissolution rate.

Currently, spray drying is widely used as a powder manufacturing process for amorphous solid dispersions. In this experiment, it was confirmed that freeze granulation is easier to achieve amorphization than spray drying. Furthermore, freeze granulation is capable of producing dry powder at low temperatures without applying heat, so it is expected to improve the quality of amorphous solid dispersions in terms of thermal effects as well.

Our spray dryers have a proven track record in the drying and granulation process of amorphous solid dispersions. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.