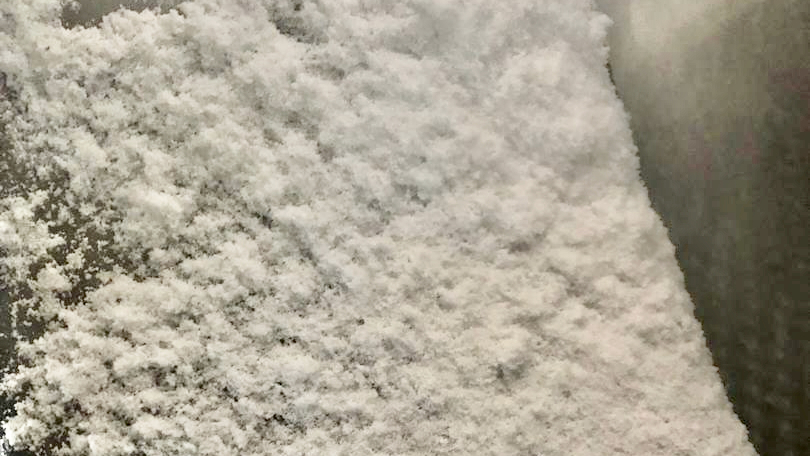

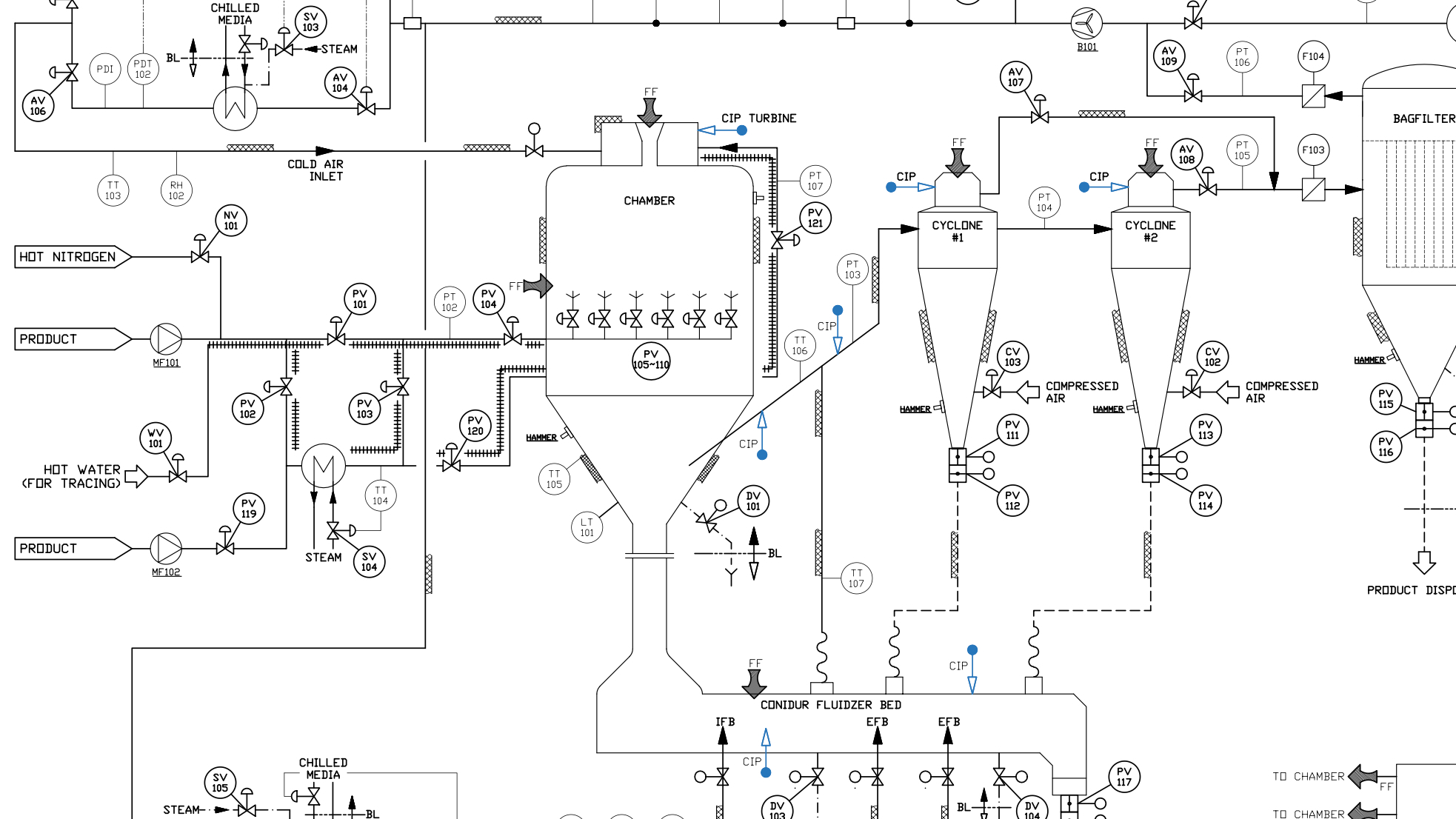

Spray congealing allows for coating, masking, and microencapsulation during the powder production process. Spray cooling and solidification process using a spray cooler continuously produces spherical granules by atomizing a molten liquid material into a cooled air stream and rapidly cooling and solidifying the atomized droplets. By dispersing a core substance within a heated and molten liquid material, the core substance is sealed in the granules that are cooled and solidified. Granules produced by spray congealing are spherical, have excellent fluidity, and a sharp and stable particle size distribution. Granules are also called beads or prills, and can generally be produced in the range of several tens of micrometers to several millimeters.

The main purposes of coating, masking and microencapsulation are as follows:

- Granulation of particles

- Powderization of liquid substances

- Protection and stabilization of core substances

- Controlling the release rate of core substances

Melting substances used as bases include wax, emulsifying wax, paraffin, saturated fatty acids, glycerin, stearyl alcohol, PEG, mono-, di-, and triglycerides.

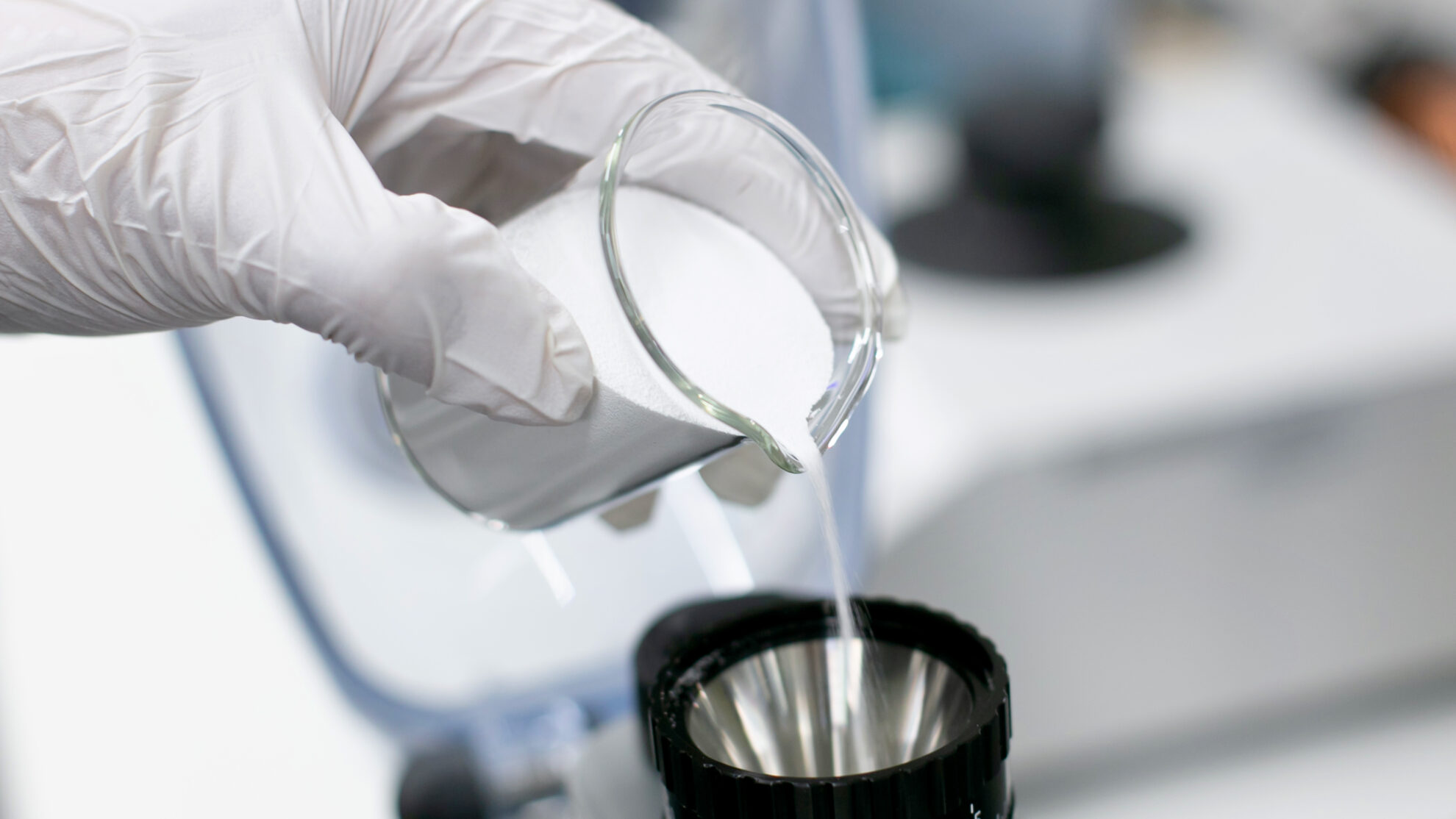

Applications are widespread, primarily in the food, pharmaceutical, and chemical industries, including various functional foods and pharmaceutical intermediates based on saturated fatty acids such as stearic acid, phospholipids, palm oil emulsifying wax, sodium stearoyl lactylate, omega-3 fatty acids, omega-6 fatty acids, microcapsules for poorly soluble pharmaceuticals, functional resins, and polymers. Encapsulation can be easily achieved by using molten substances as the membrane material and mixing the core substance into the molten liquid. Unlike spray drying, there is almost no moisture in the molten liquid, which increases the encapsulation efficiency. For this reason, spray congealing is used in a variety of fields, primarily in the oil and fat industry.

Spray congealing is a relatively inexpensive and simple continuous process that can produce spherical granules with good flowability. Compared to a spray dryer, the process does not require a large-capacity heat source, making it more energy efficient. The process can be used for continuous mass production in a single step, making it possible to omit steps such as grinding, classification, and granulation. By properly mixing raw materials and designing the process, spray coolers can be used to design particles according to the purpose, such as granules with the core material completely embedded or granules with part of the core material exposed on the surface.

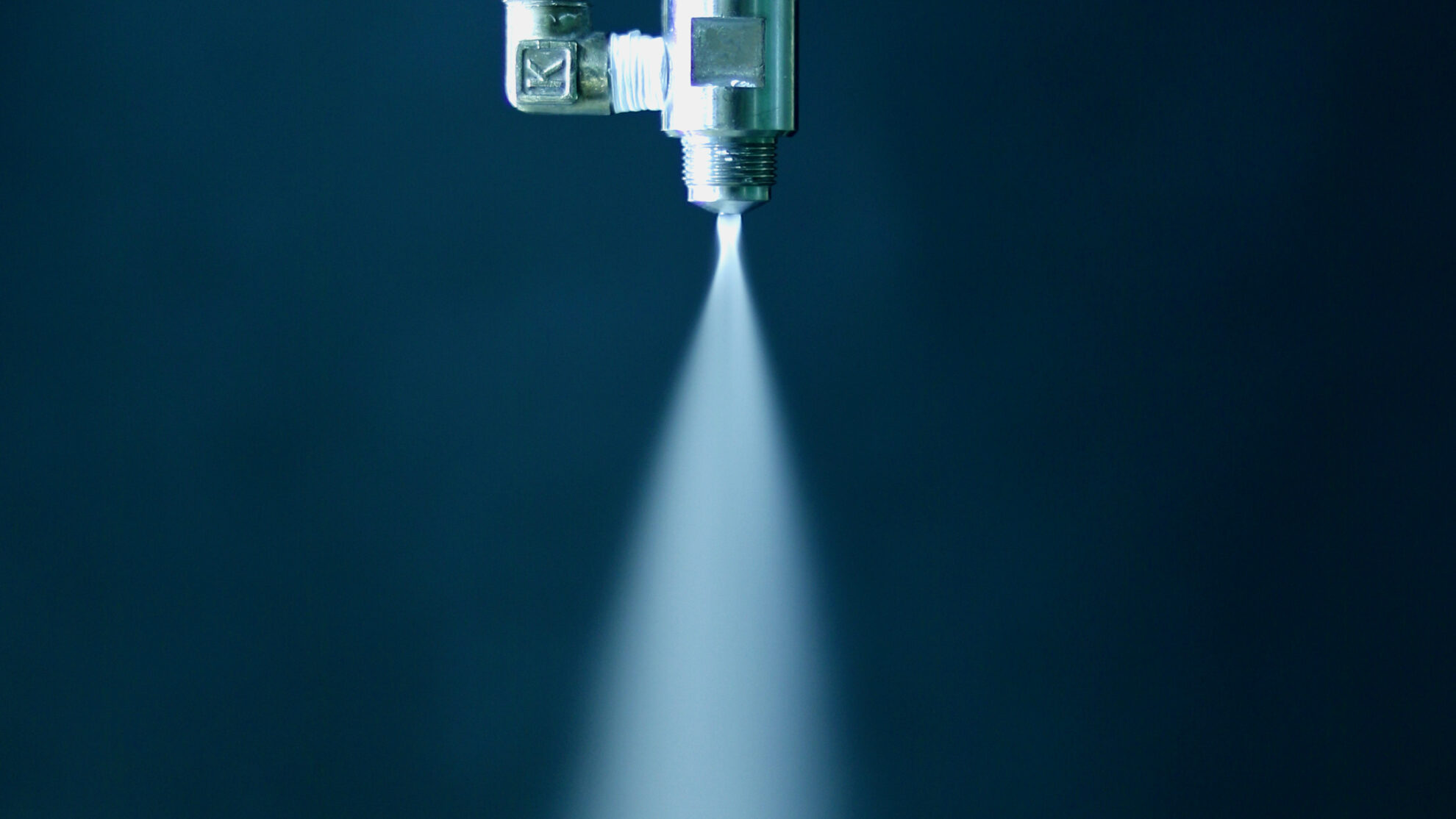

Our spray coolers have a proven track record in applications with coating, masking and microencapsulation. Based on our accumulated experience and expertise, we design optimal spray congealing processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray congealing process, we control powder quality that exceeds customers’ expectations. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. When selecting an atomization method, not only the droplet size but also the effects of physical contact and friction must be taken into consideration.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.