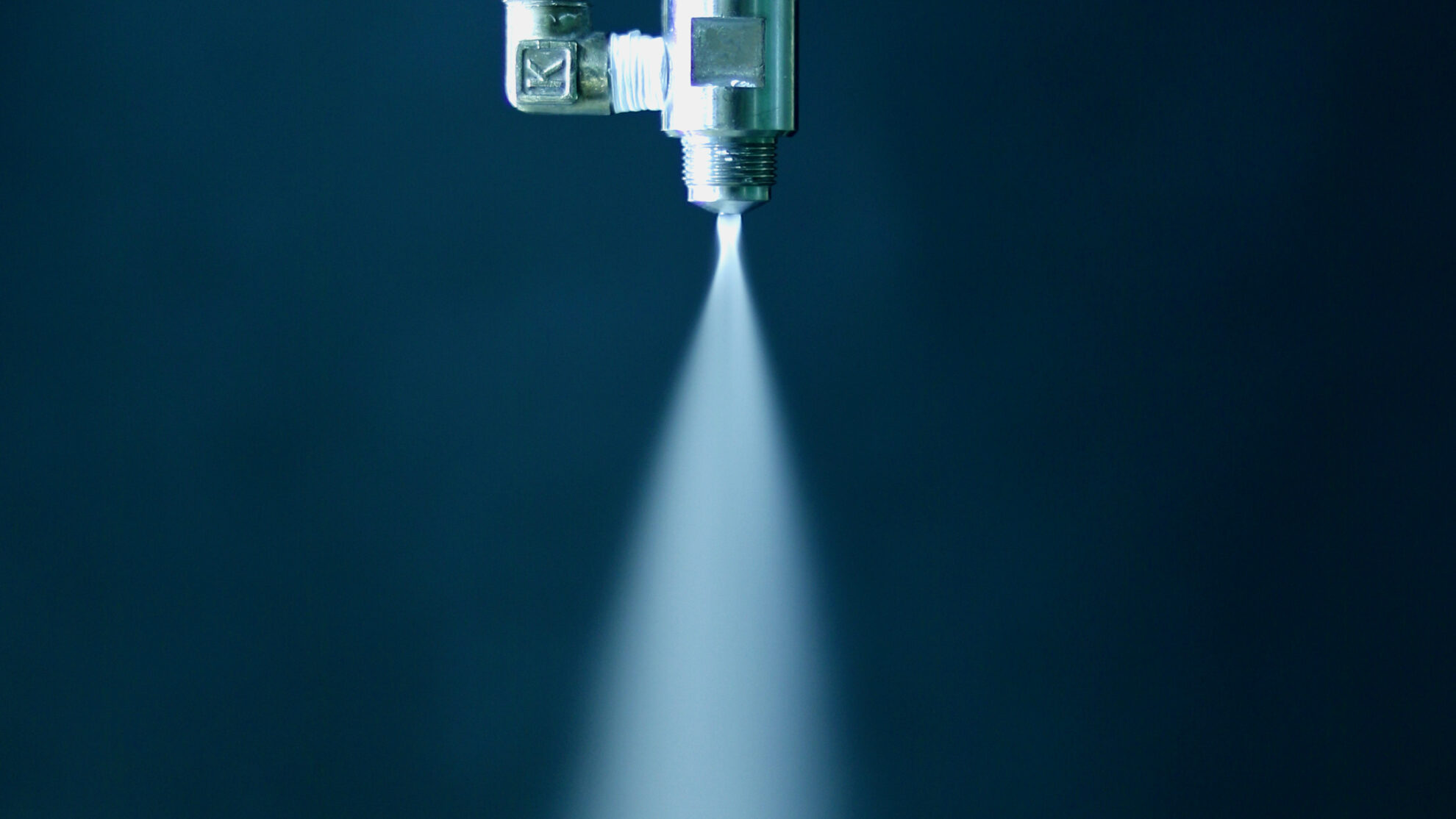

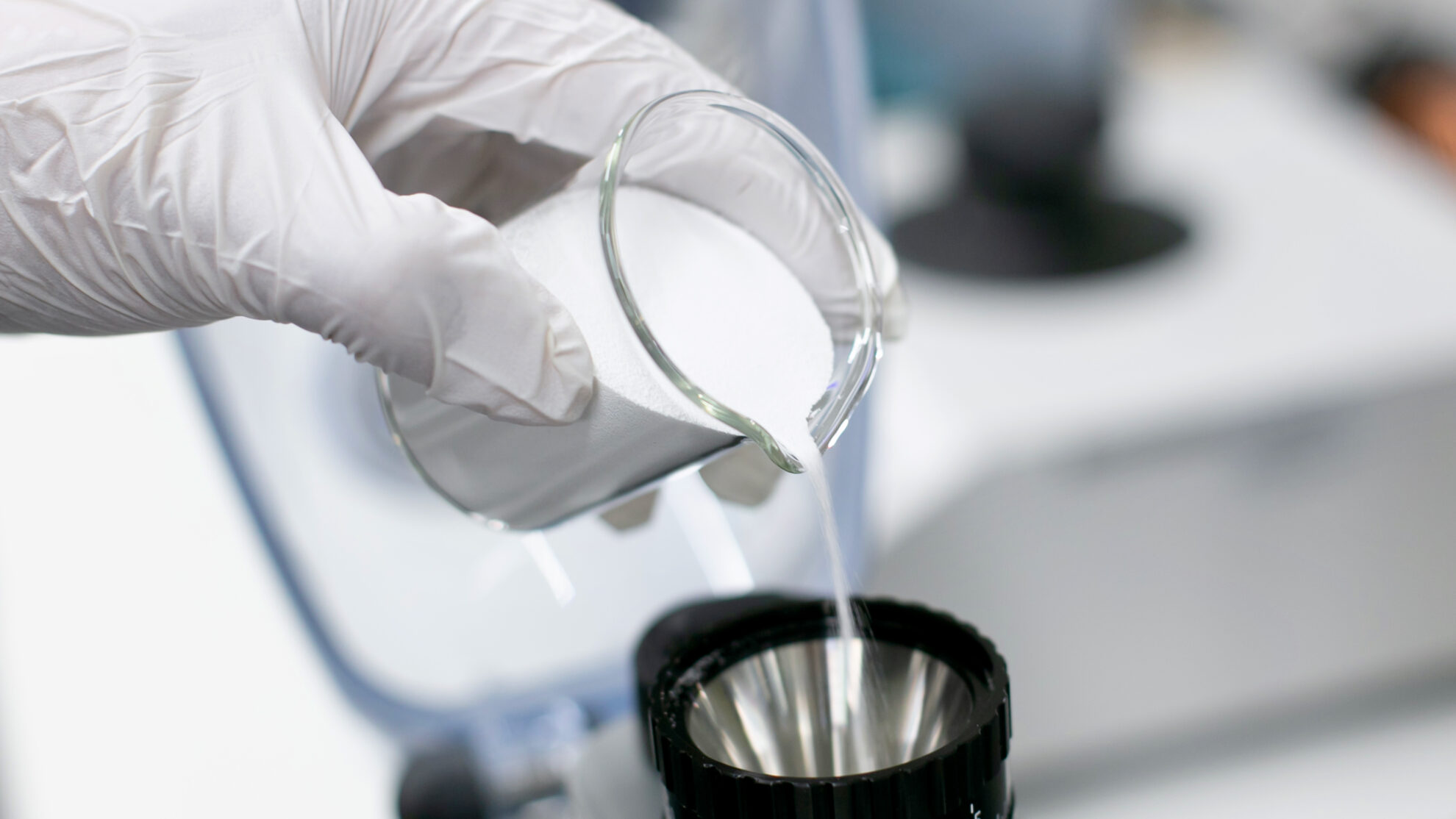

Spray drying is a continuous process that produces dry powders by spraying liquid materials into a stream of hot air and rapidly drying them, allowing for coating, masking and microencapsulation during powder production. By adding a polymer to the liquid material as a wall substance, it is possible to form a thin film on the core material. The thickness of the film can be controlled by adjusting the type and amount of wall substance added.

Wall materials include starches such as dextrin, sugar solutions, gelatin, gum arabic, binders such as PVA, PVP, and PEG, aminoacrylic methacrylate copolymers, and cellulose-based materials such as hydroxypropyl cellulose (HPC), hydroxypropyl methylcellulose (HPMC), ethyl cellulose, and cellulose acetate phthalate. For microencapsulation, glycerin, oil and fat materials, cellulose-based substances, polylactic acid, and other polymeric substances are also used.

The main purposes of forming a membrane are:

– Granulation of particles

– Powderization of liquid substances

– Protection and stabilization of core substances

– Release rate control of core substances

There are a wide range of applications in this field, mainly in food, pharmaceuticals, chemicals, and inorganic materials. In food and pharmaceuticals, they are used to mask bitterness and odors, improve stability by protecting against oxygen, water, light, etc., control disintegration and strength, and control sustained release and enteric from the perspective of drug delivery systems (DDS). There are many applications, from simply obtaining granules using a binder to powdering useful oils such as EPA and DHA, preventing the oxidation of vitamins, powdering liquid substances, preserving the flavor of fragrances, improving solubility by making substances amorphous, providing sustained release properties to pharmaceuticals and pesticides, controlling the release time of multiple core substances in DDS, etc. In addition, a wall substance may be added to waste liquid and spray-dried to seal in toxicity, before recovering it as a dry powder. For example, volatile components usually have low boiling points and evaporate during spray drying, but adding maltodextrin, cyclodextrin, oligosaccharides, etc. makes it possible to retain the components. For example, cyclodextrin can encapsulate the molecules of volatile components within its hydrophobic cavity, reducing the loss of components during spray drying. This is effective in slowing the release of flavor components in products. Similarly, by adding an appropriate concentration of coating additives and spray drying at low temperatures, it is possible to produce powders containing alcohol, such as powdered alcohol, that retain a high residual alcohol content. When high-quality powdered alcohol is redissolved in water, it is possible to restore not only the alcohol but also the flavor of the liquid alcohol.

To properly form a film, it is important not only to adjust the liquid material but also to optimize the operating conditions of the spray dryer. Compared to other drying processes, spray drying is said to require a shorter drying time and has less thermal impact. However, if there is concern about thermal denaturation of the core substance, it is necessary to appropriately set the operating conditions of the spray dryer, such as the drying temperature and amount of process gas. In addition to adjusting the liquid material by adding additives, oxidation can also be prevented from a process perspective by using an inert gas as the process gas for the spray dryer.

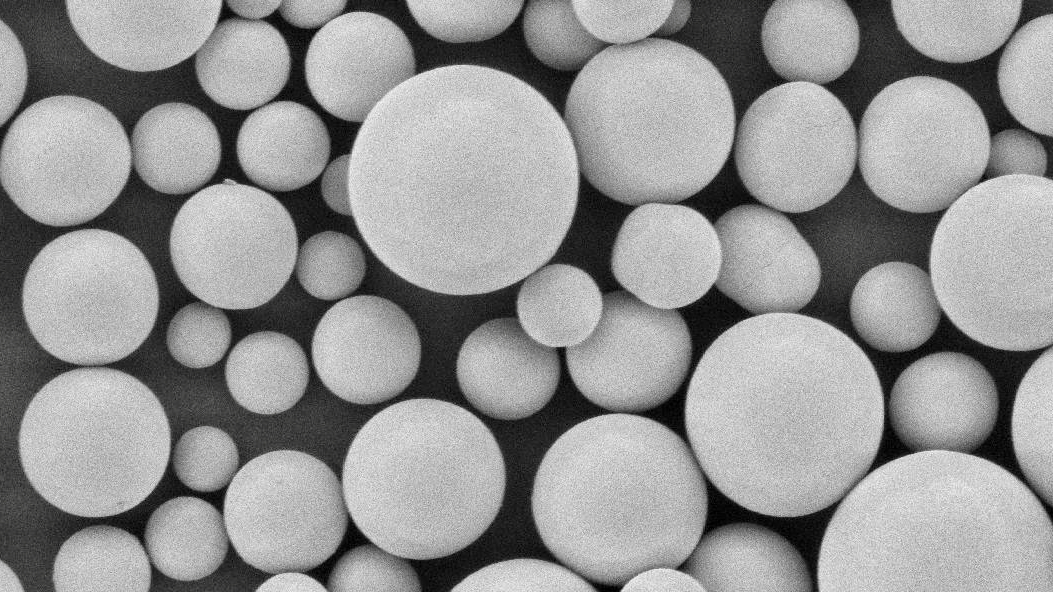

In general, spray drying involves the evaporation of the solvent from the droplet surface, and the movement of moisture from the droplet to the surface, causing the entire droplet to shrink. At the same time as the moisture moves, the solid content within the droplet moves outward, forming a particle structure. As a result, the particles tend to have a high density outer shell and a low density or hollow interior. Furthermore, in suspensions, if there are multiple particle components contained in the liquid and each particle has a different particle size and density, segregation may occur inside the granules due to particle movement during drying. It is important to understand the physical properties of the raw materials and the particle size, density, internal structure, etc. of the particles, and then control the operating conditions appropriately.

The film thickness and coating rate are affected by the internal structure of the granules, such as density and porosity. For this reason, a wall material may be added to a slurry containing extremely small particles such as silica, talc, or pyrophyllite and core material particles, and then spray-dried to form an inorganic shell on the outer shell of the core material. Below is an experiment we conducted about the surface treatment of ceramic particles. We investigated the feasibility of using the spray drying method for surface treatment of fine particles.

* The results of this experiment were presented jointly by PRECI and the (then) Malvern Division of Spectris Co., Ltd. at the 30th Autumn Symposium of the Ceramic Society of Japan in 2017.

Experiment 1: Spray drying of silica fine particle slurry with different PVA concentrations

Spray dryer

Model: Spray dryer TR160

Atomization mode: Two-fluid nozzle

Product collection method: Cyclone

Operating conditions

Inlet temperature: 150°C

Outlet temperature: 75 – 80°C

Feed rate: 5kg/h

Nozzle pressure: 0.5MPa

Slurry conditions

1. Silica 12.5wt%, PVA 0.6wt%, water 86.9wt%

2. Silica 12.5wt%, PVA 1.2wt%, water 86.3wt%

3. Silica 25.0wt%, PVA 1.2wt%, water 73.8wt%

4. Silica 6.3wt%, PVA 0.3wt%, water 93.4wt%

Evaluation method

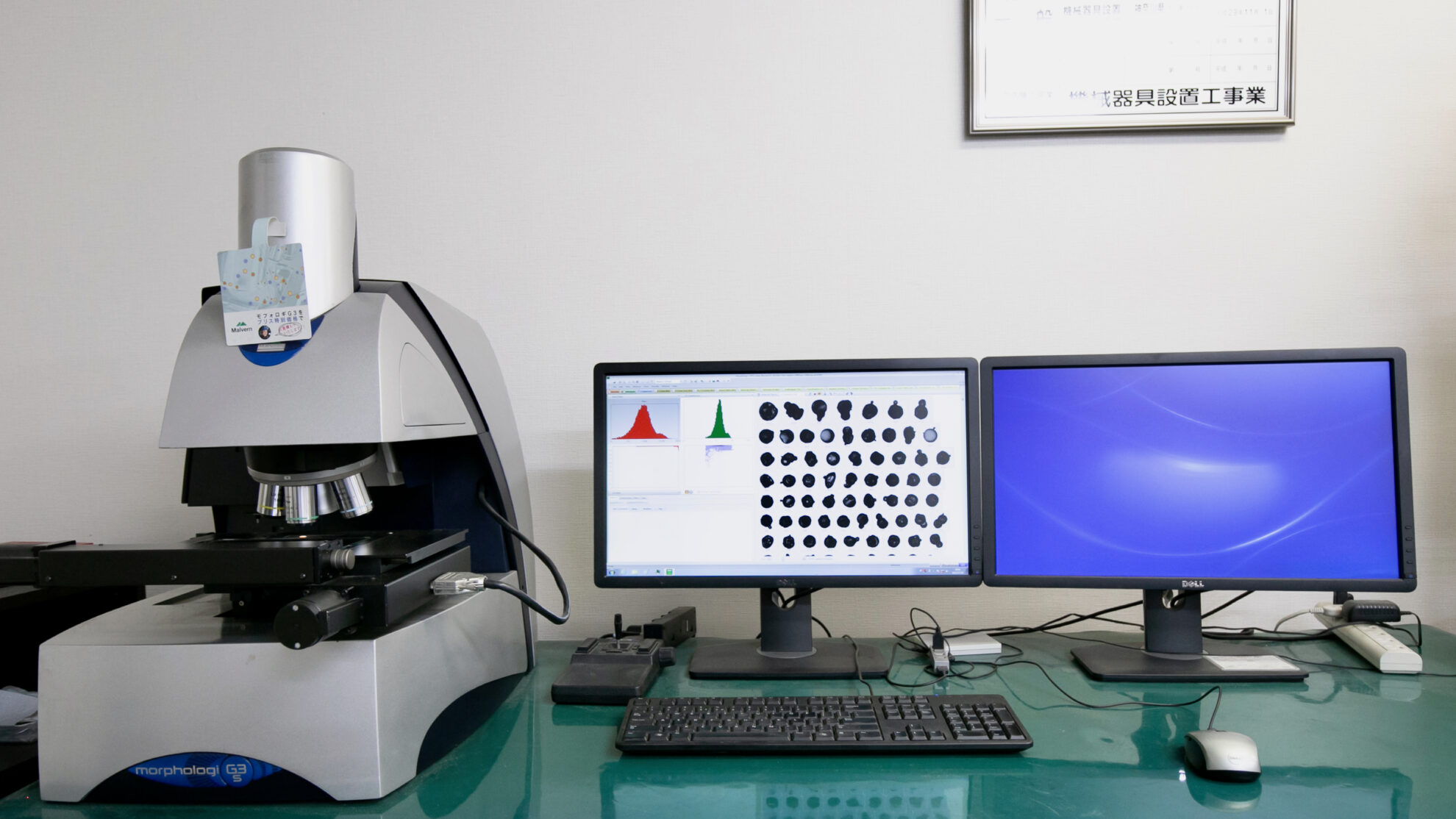

Particle image analyzer: Morphologi G3 (Malvern Panalytical)

Dispersed particles are imaged to evaluate particle size, shape, etc.

Morphologi G3

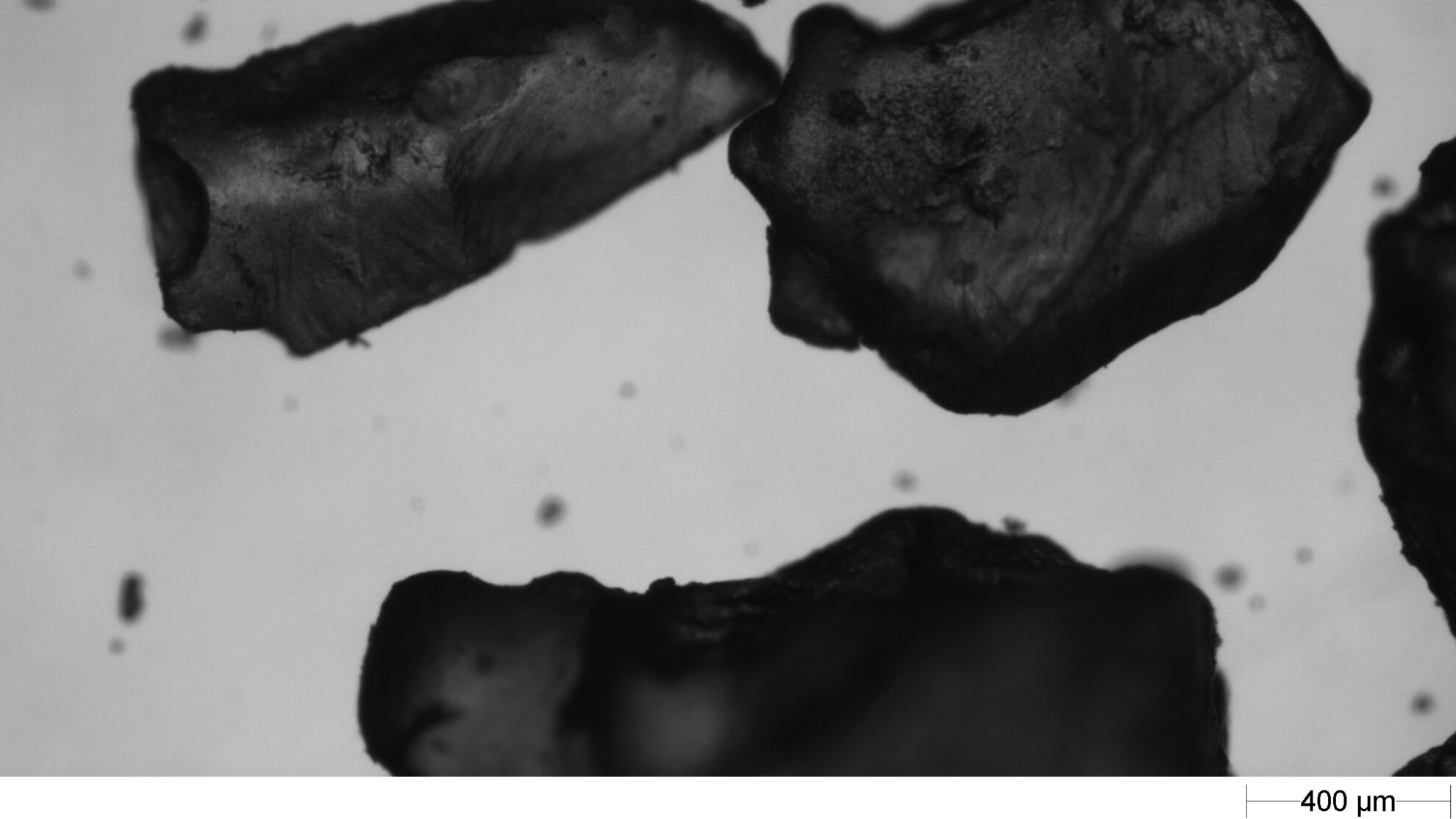

Silica (raw material)

Silica (after ball milling)

Silica was processed in a ball mill for 88 hours to produce four types of slurry, which were then spray-dried. The particle size distribution (Dv50) of the slurry after ball milling was 5.1μm.

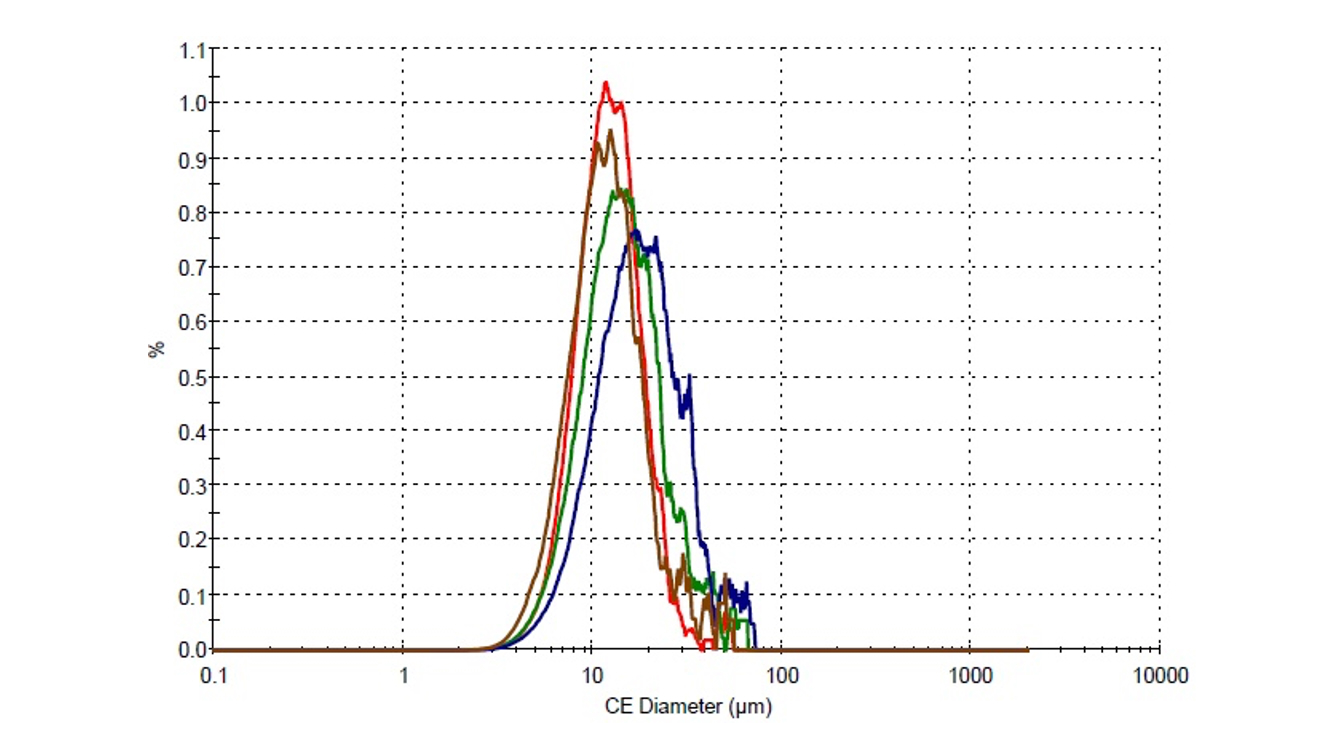

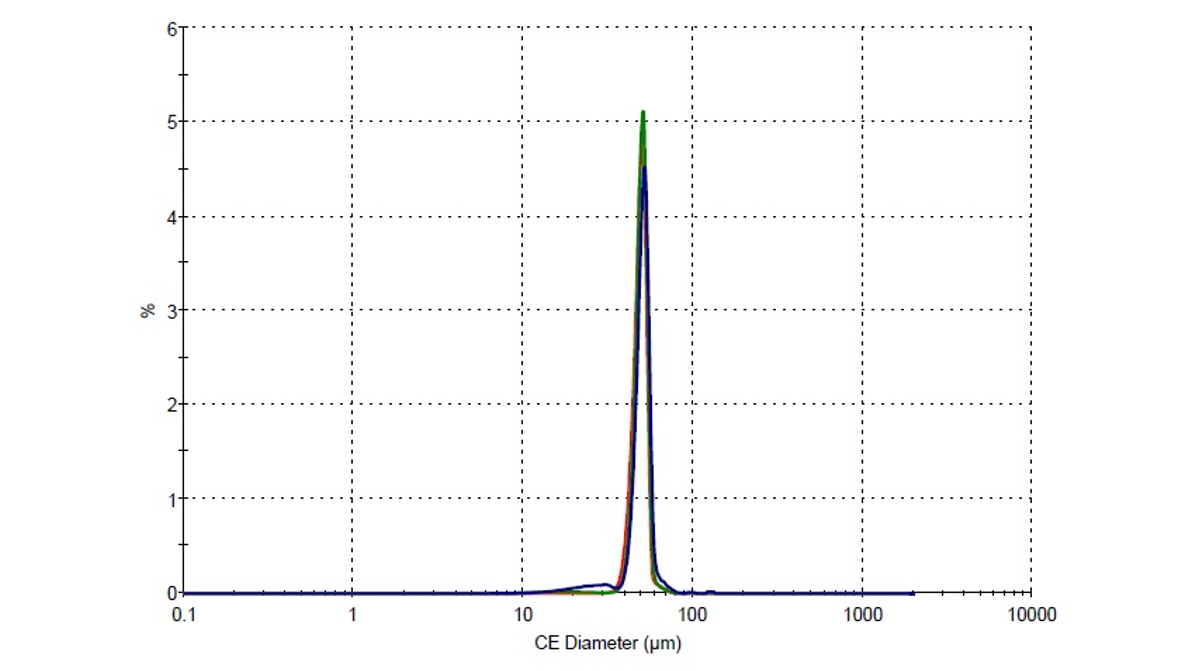

Image analysis result 1: Particle size distribution (Dv50)

The size of the particles increased in proportion to the silica concentration and PVA concentration.

Graph (Red): 12.5% silica, 0.6% PVA: 12.1μm

Graph (Green): 12.5% silica, 1.2% PVA: 14.1μm

Graph (Blue): 25.0% silica, 1.2% PVA: 17.4μm

Graph (Brown): 6.3% silica, 0.3% PVA: 11.7μm

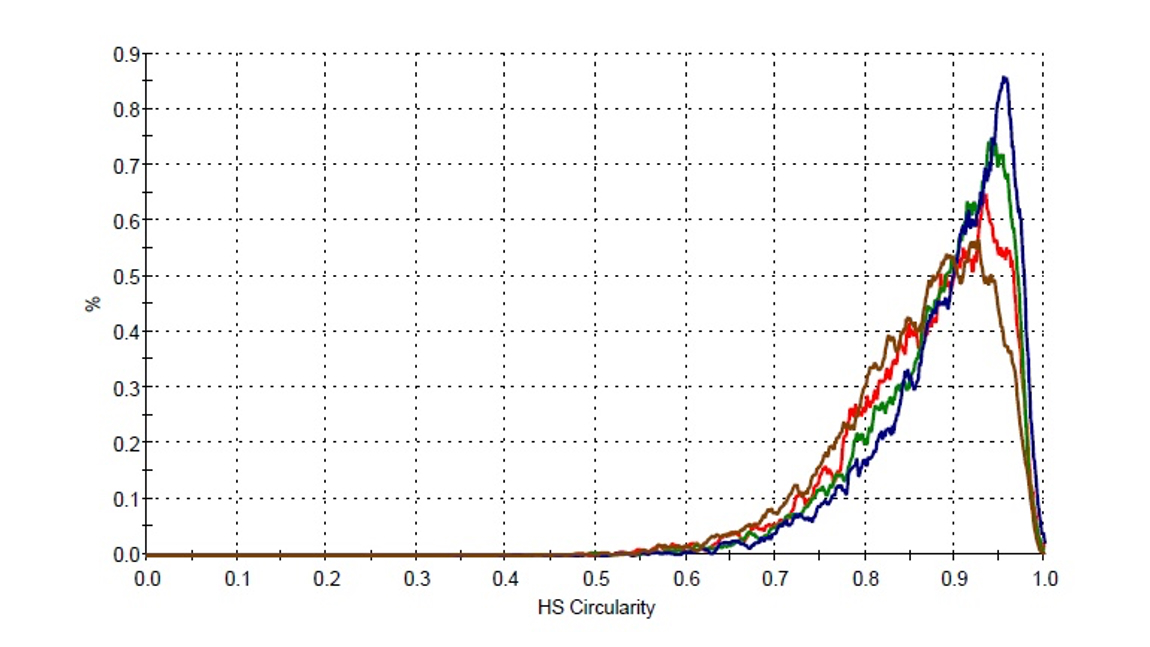

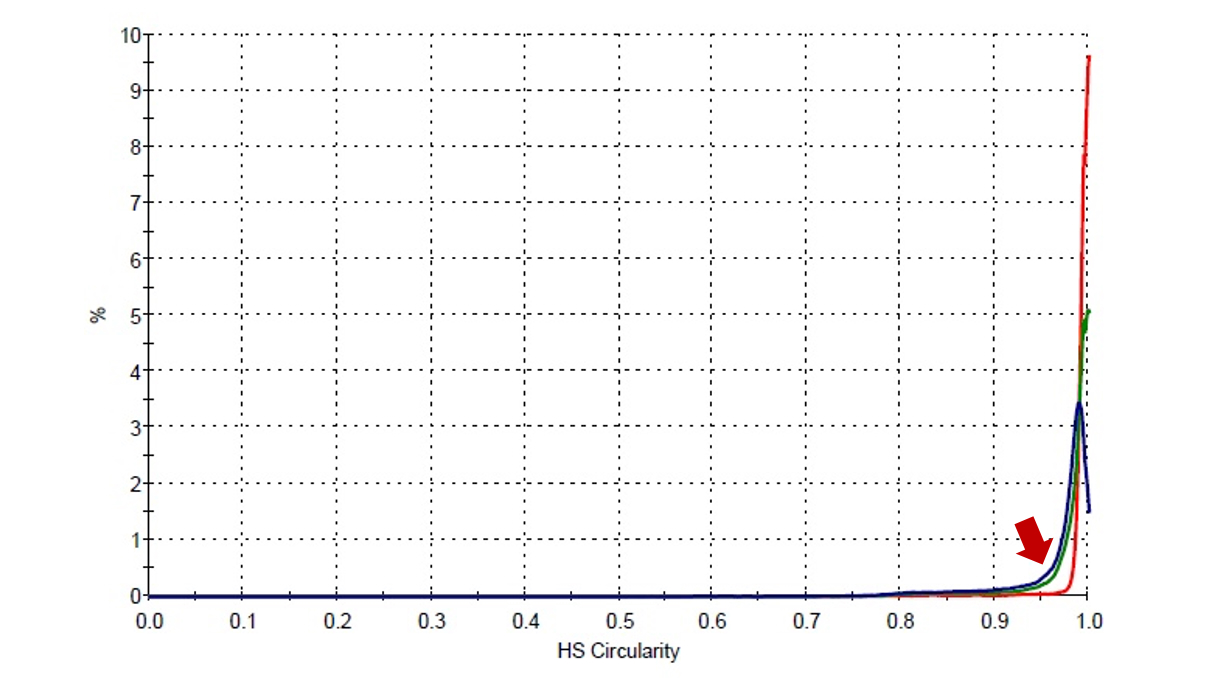

Image analysis result 2: Circularity after extraction by brightness value (Dn50)

The higher the silica and PVA concentration conditions, the more coating there was.

Graph (Red): 12.5% silica, 0.6% PVA: 0.89

Graph (Green): 12.5% silica, 1.2% PVA: 0.90

Graph (Blue): 25.0% silica, 1.2% PVA: 0.91

Graph (Brown): 6.3% silica, 0.3% PVA: 0.87

Experiment 2: Coating glass beads with alumina powder and PVA using spray drying

Spray dryer

Model: Spray dryer TR160

Atomization mode: Rotary atomizer

Product collection method: Chamber and cyclone (only the recovered powder under the chamber is evaluated.)

Operating conditions

Inlet temperature: 200°C

Outlet temperature: 80 – 90°C

Feed rate: 5kg/h

Rotary atomizer speed: 6,000rpm/12,000rpm

Slurry conditions

Glass beads 18.0wt%, alumina 1.8wt%, PVA 0.2wt%, water 80.0wt%

Evaluation method

Particle image analyzer: Morphologi G3 (Malvern Panalytical)

Spray drying was performed with the rotary atomizer rotational speed set to 6,000 rpm and 12,000 rpm. *The particle size distribution of the glass beads was Dv50: 49.1μm, and that of the alumina powder was Dv50: 0.5μm.

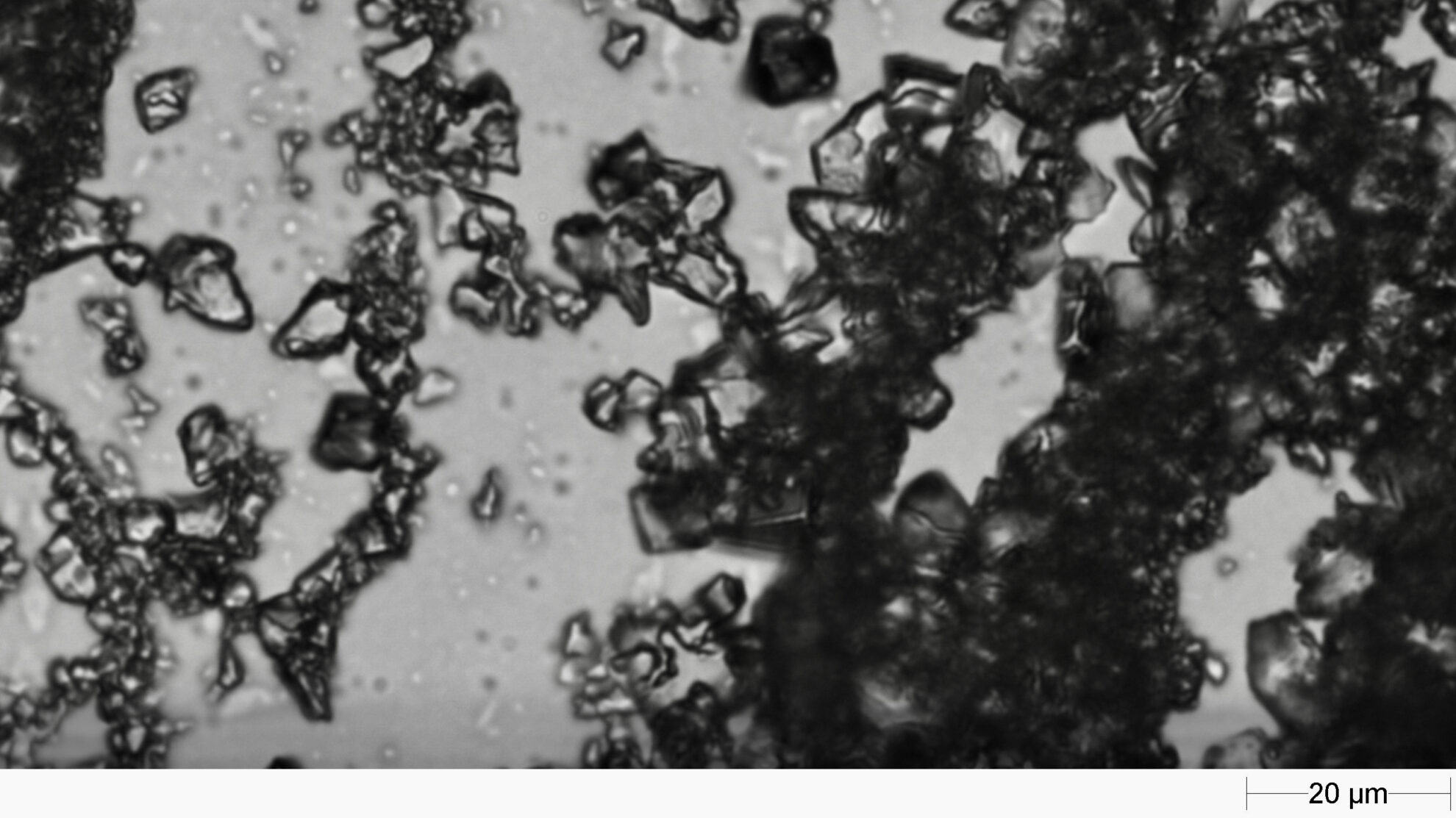

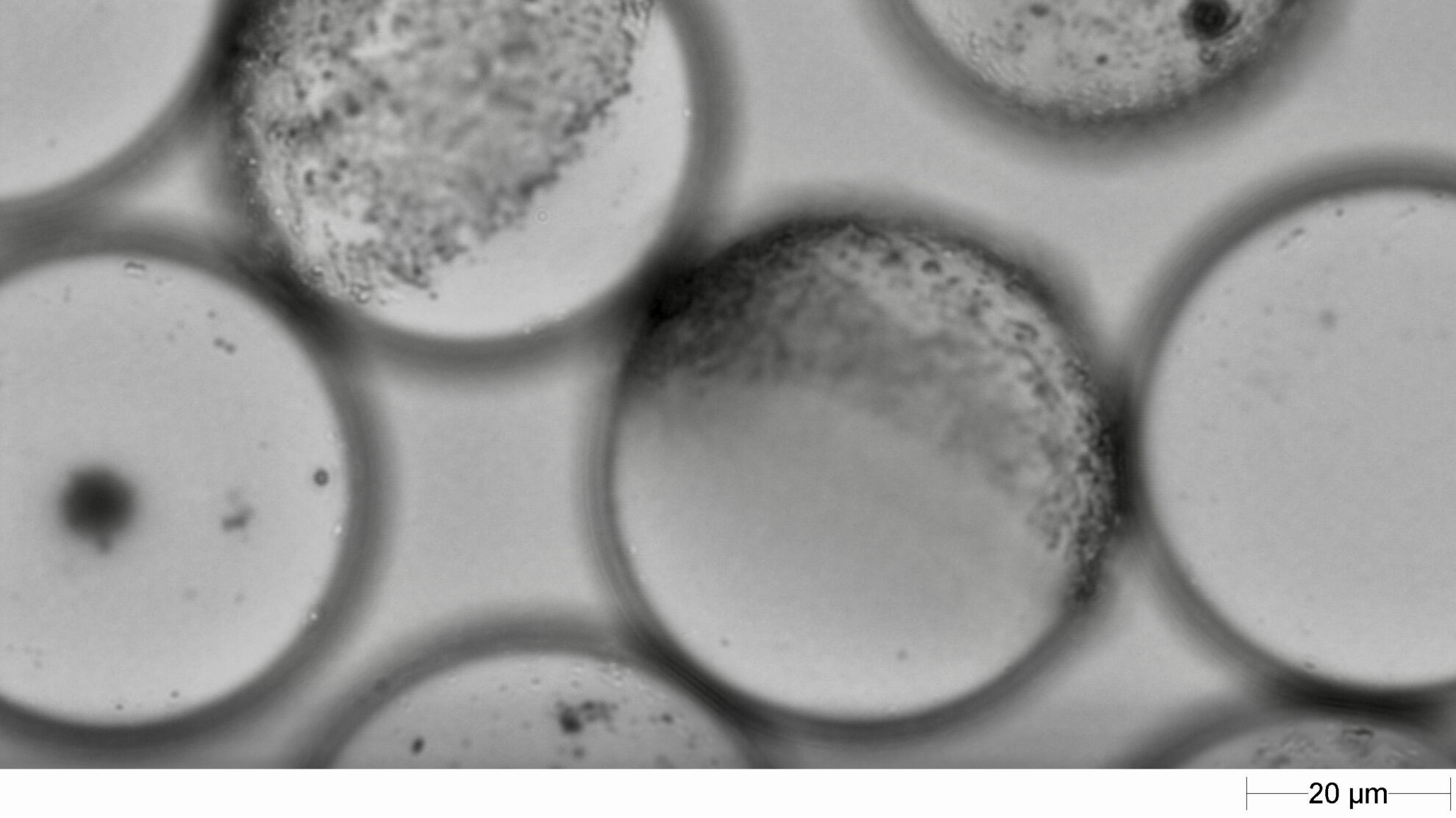

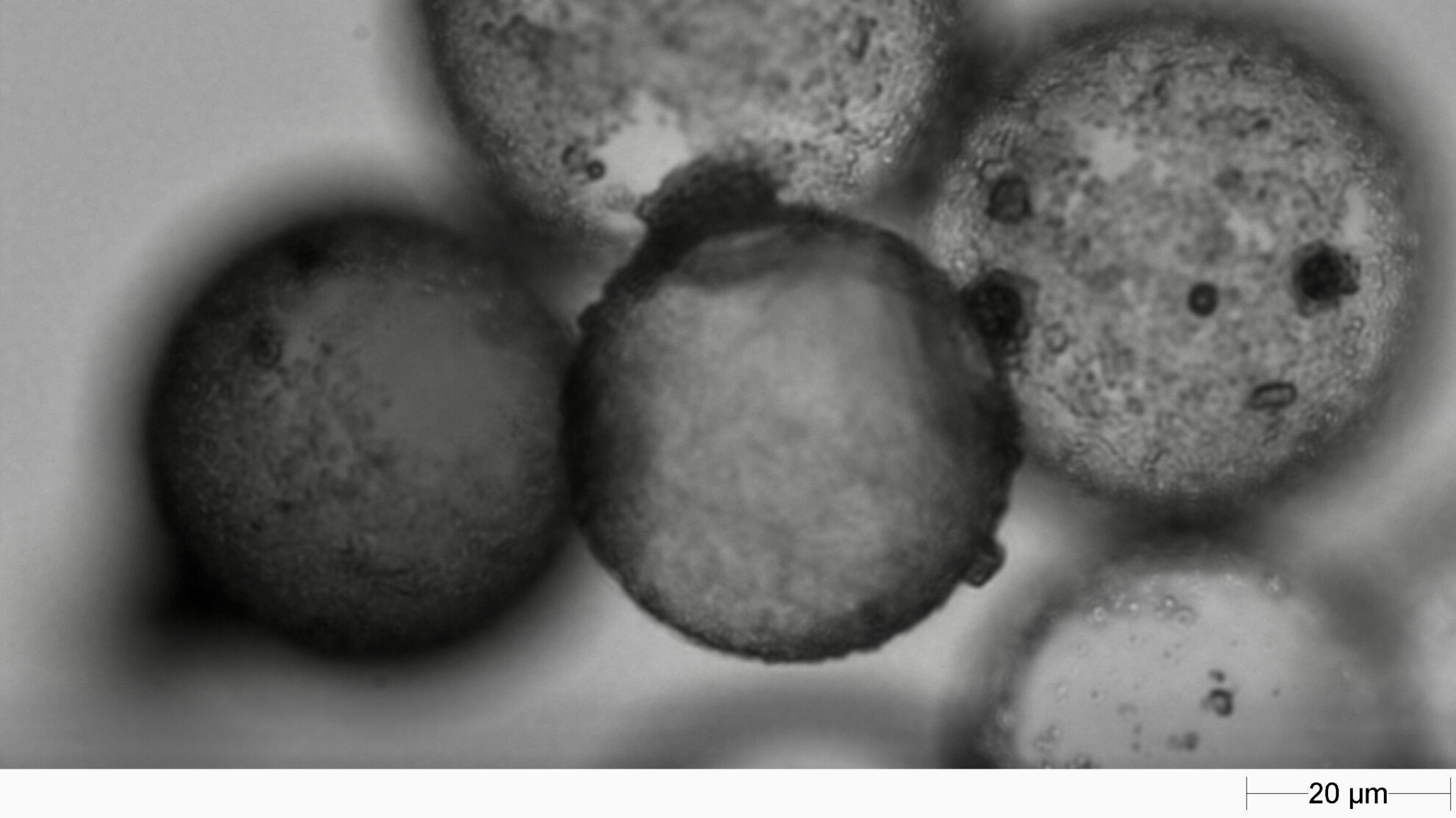

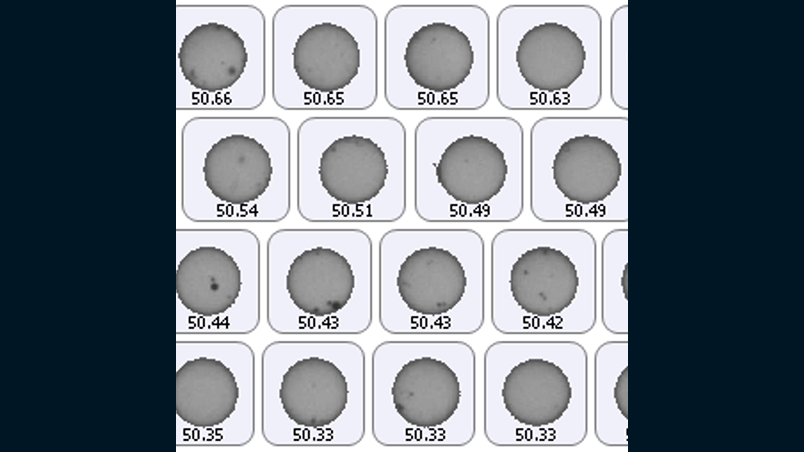

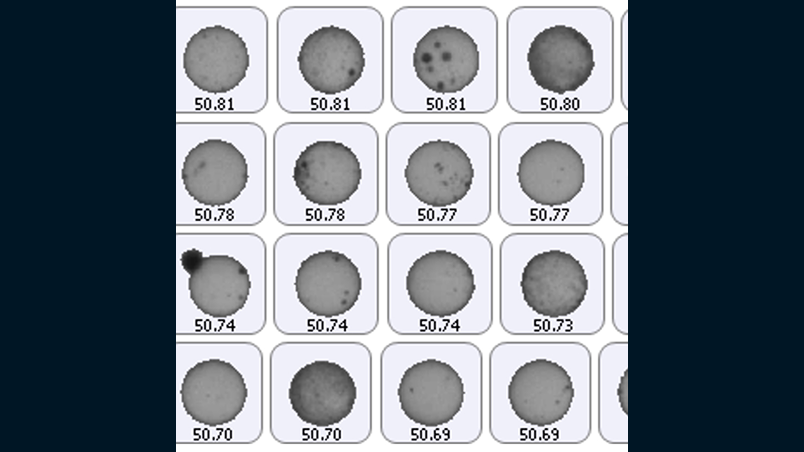

Image analysis result 1: Coating appearance

12,000rpm

6,000rpm

The appearance of the coating was confirmed by transmitting light only through the glass beads using the immersion light transmission method. Under the 12,000 rpm condition, the high rotational speed resulted in small droplets, and only partial coating of the glass beads was observed. On the other hand, under the 6,000 rpm condition, the slow rotational speed resulted in larger droplets, and the alumina was completely coated.

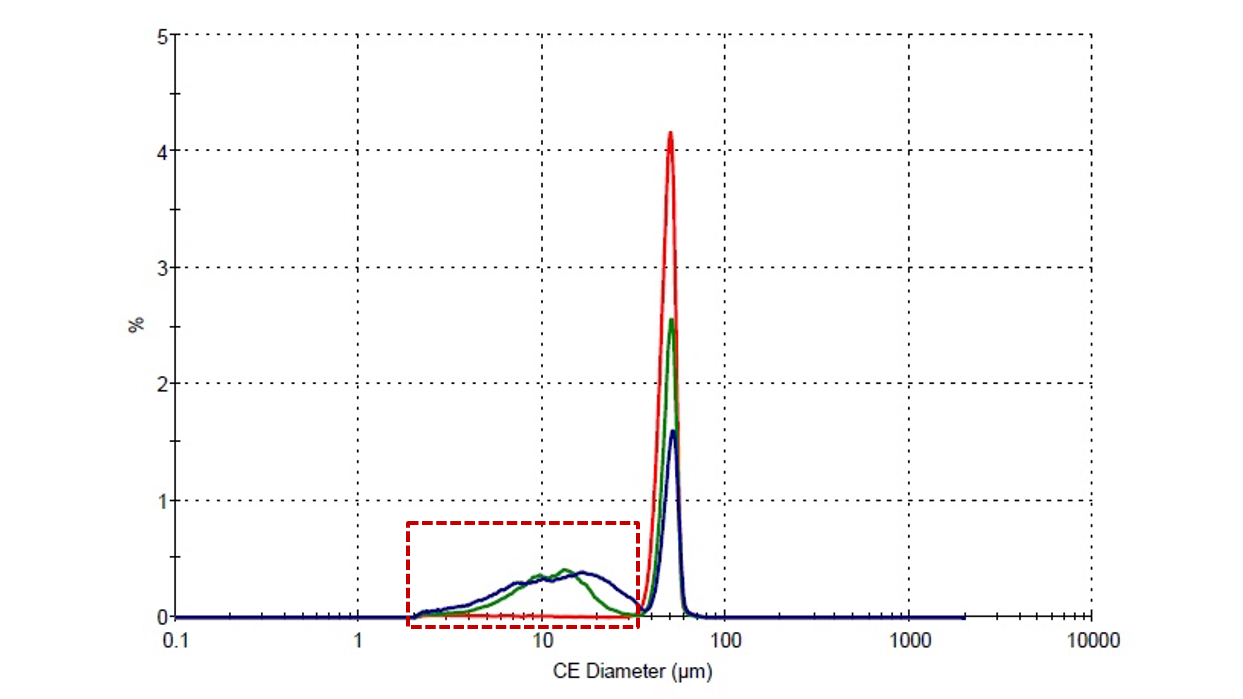

Image analysis result 2: Particle size distribution and particle shape (dry)

Particle size distribution (Dv50)

The granules were larger under the 6,000 rpm condition, resulting in a higher coverage rate. However, since the alumina powder had a Dv50 of 0.5μm, it was not possible to determine whether multiple layers were formed.

Graph (Red): Glass beads: 49.1μm

Graph (Green): 12,000rpm: 49.8μm

Graph (Blue): 6,000rpm: 50.6μm

Particle size distribution (Dn50)

It was confirmed that there were fine particles that were not glass beads, as well as aggregates of uncoated alumina powder and PVA.

Circularity (Dn50)

The circularity (Dn50) results were comparable. For Dn10, the glass beads was 0.98, while the 12,000 rpm condition was 0.93, and the 6,000 rpm condition was 0.89. The 6,000 rpm condition had a lower circularity.

Graph (Red): Glass beads: 0.99

Graph (Green): 12,000rpm: 0.99

Graph (Blue): 6,000rpm: 0.98

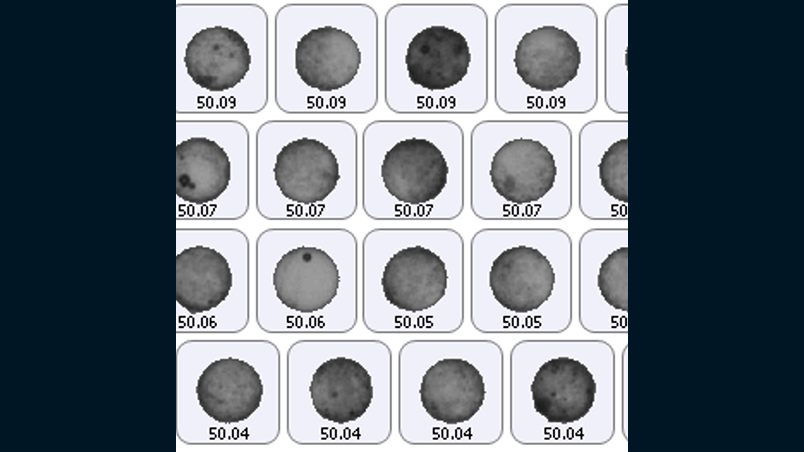

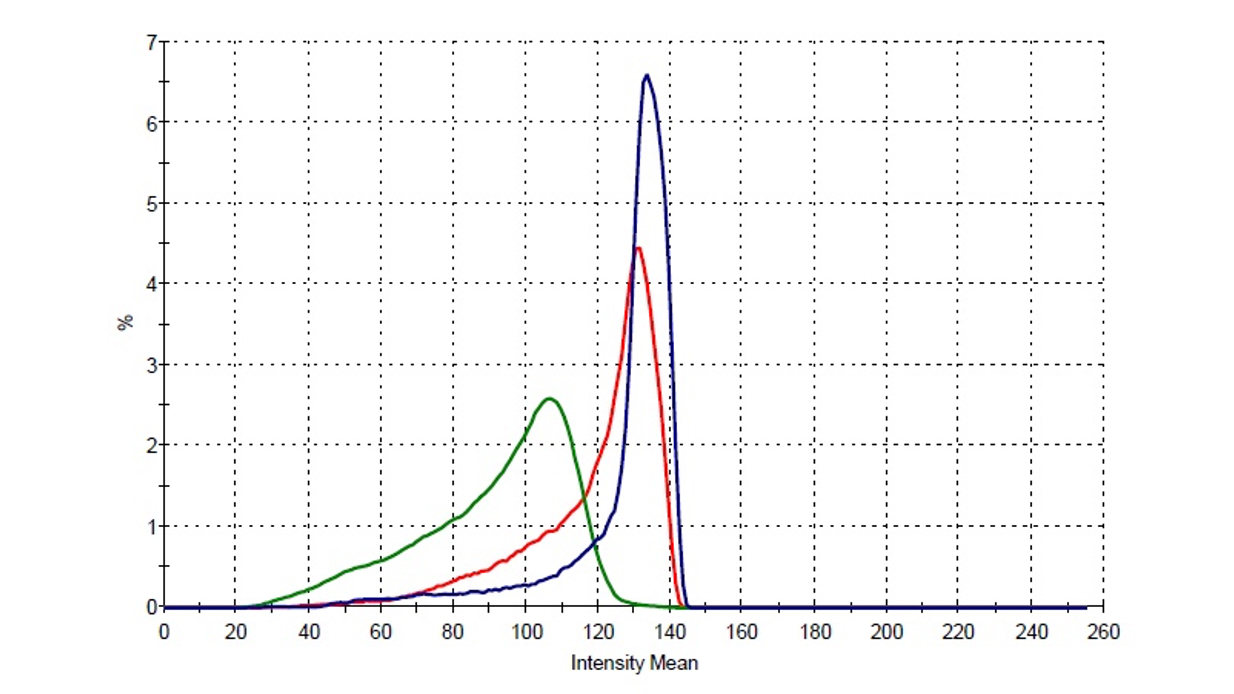

Image analysis result 3: Brightness value (Dn50)

Glass beads (Blue in the graph)

12,000rpm (Red in the graph)

6,000rpm (Green in the graph)

Brightness value (Dn50)

By using the immersion transillumination method to transmit light through glass beads, the amount of alumina coating, which opposes transmission, correlates with brightness value. Therefore, the amount of coating was quantified by combining immersion transillumination and image analysis. Because brightness value depends on particle size, we limited particle sizes to 40 – 60μm and calculated the average brightness value. As a result, we were able to confirm certain differences across conditions.

Our spray dryers have a proven track record in the drying and granulation process of coating, masking and microencapsulation applications. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.