A catalyst is a substance that changes the reaction rate of a specific chemical reaction. For example, in the chemical reaction 2H2 + O2 → 2H2O, nothing happens when hydrogen gas and oxygen gas are mixed and heated, but by adding a small amount of copper (Cu), the catalytic reaction cycle of Cu and CuO is added, and water is produced. Activation energy is required to activate reactants in a chemical reaction. Using a catalyst reduces the activation energy of reactants, making it possible to promote certain chemical reactions. The action of enzymes is also a type of catalytic reaction. Amylase, a digestive enzyme found in saliva that breaks down carbohydrates, pepsin, which breaks down proteins, and lipase, which breaks down fats and oils, are all called biocatalysts.

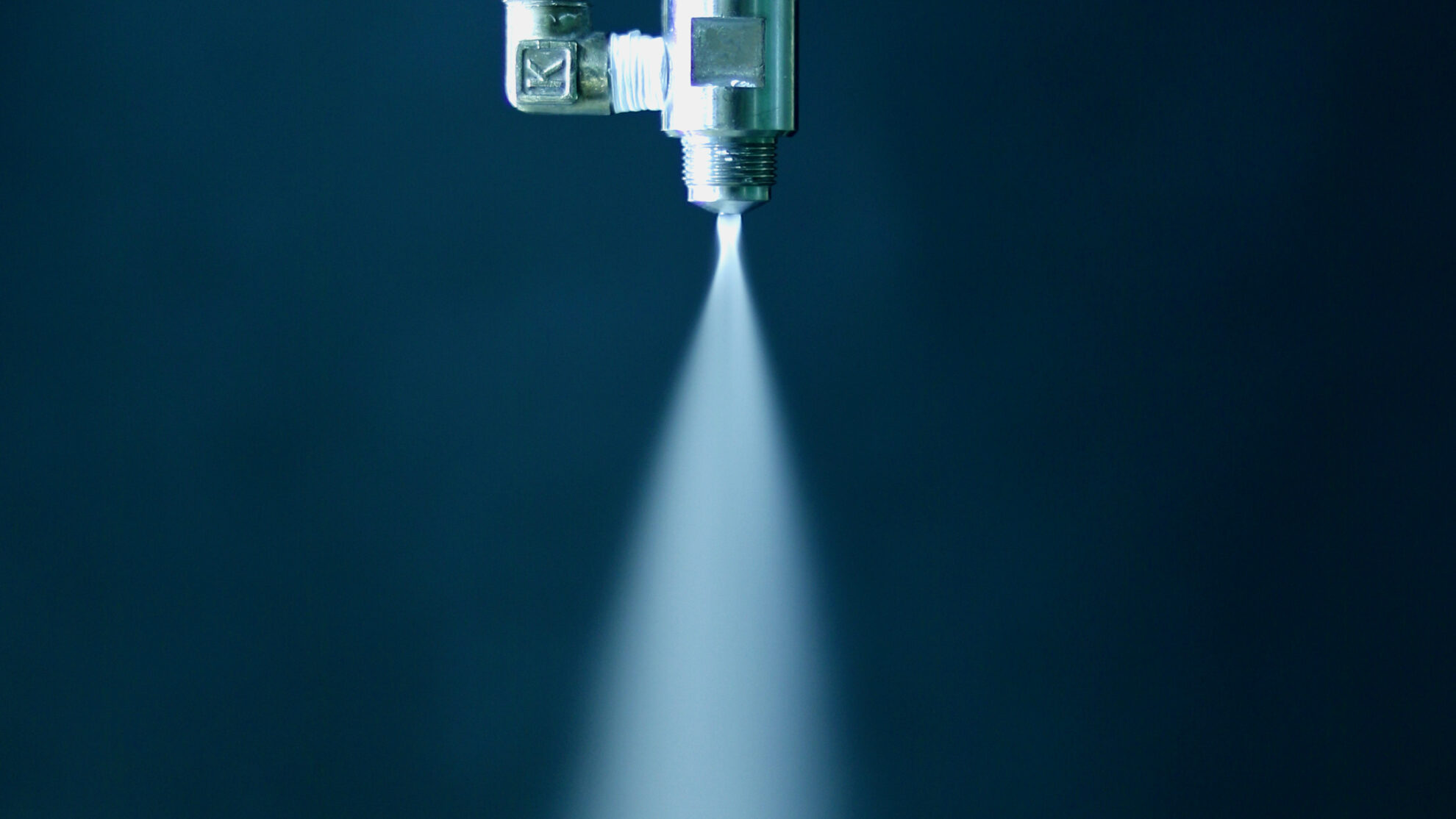

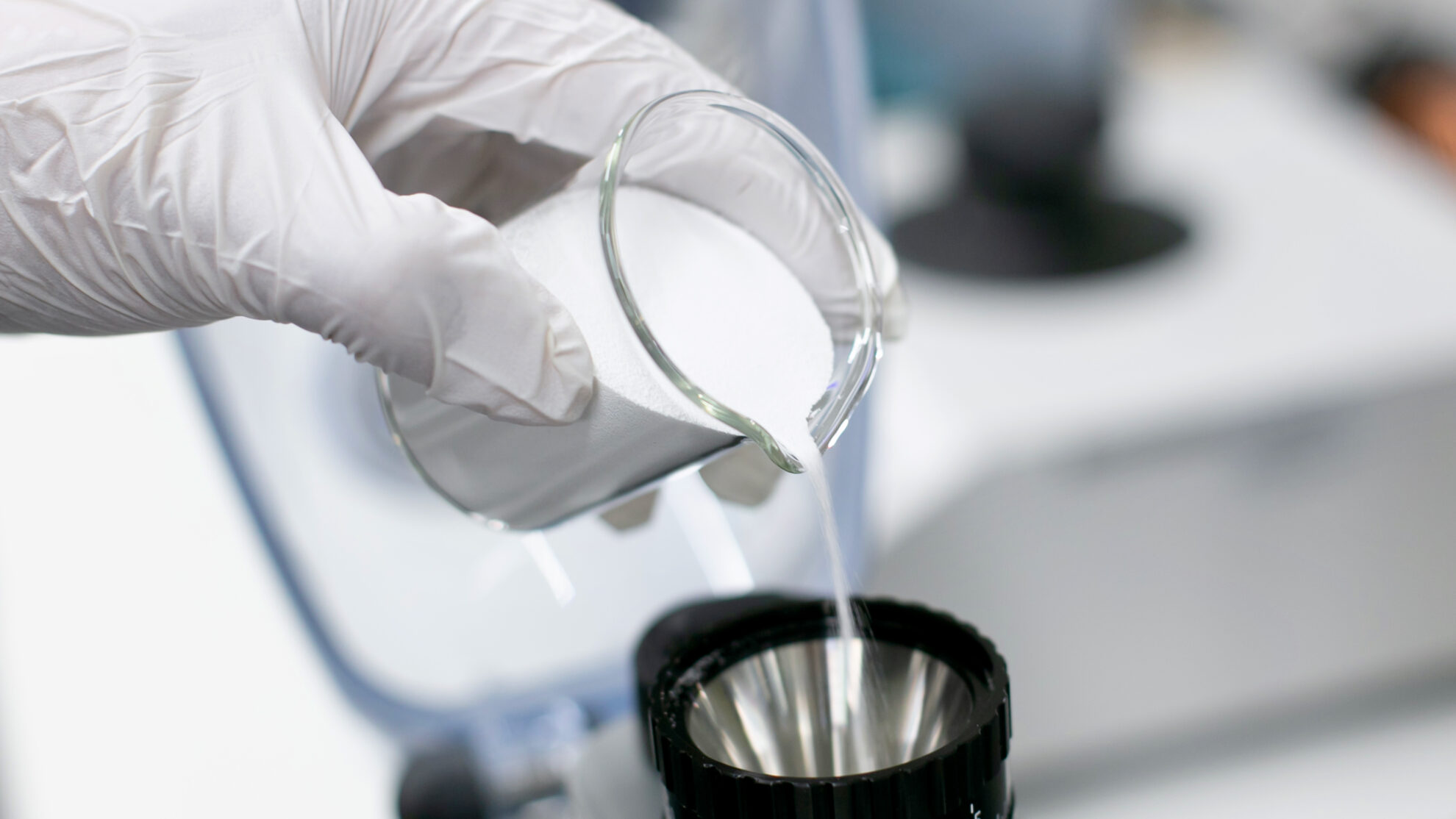

There are two types of catalysts: homogeneous catalysts and heterogeneous catalysts. The basic form of a catalyst is a solution state in a homogeneous system, while a heterogeneous system is a solid state. In a homogeneous system, there is no boundary between the catalyst and the reactants, like ions in an aqueous solution. In a homogeneous system, the catalyst is mixed evenly into the reactants, making it easier to control the reaction, but it has the disadvantage that it is difficult to remove the catalyst after the reaction. Heterogeneous systems are systems in which there is a boundary between the catalyst and the reactants, like a solid and a gas. Heterogeneous systems have the advantage of being easy to separate because they are in a solid state. For example, it is possible to dry and granulate them using a spray dryer, and then separate the solid. Heterogeneous solid catalysts can be prepared by precipitation, hydrothermal synthesis, impregnation, etc. These preparation methods often result in a solution state, which requires a drying process in a subsequent process. Using a spray dryer in the drying process makes it possible to continuously produce high-quality granules.

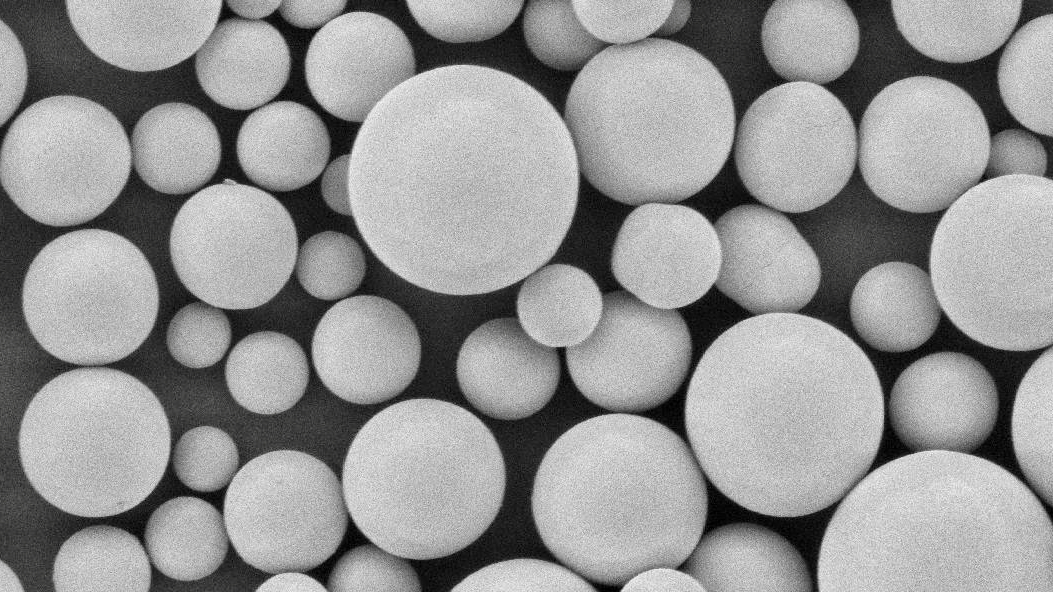

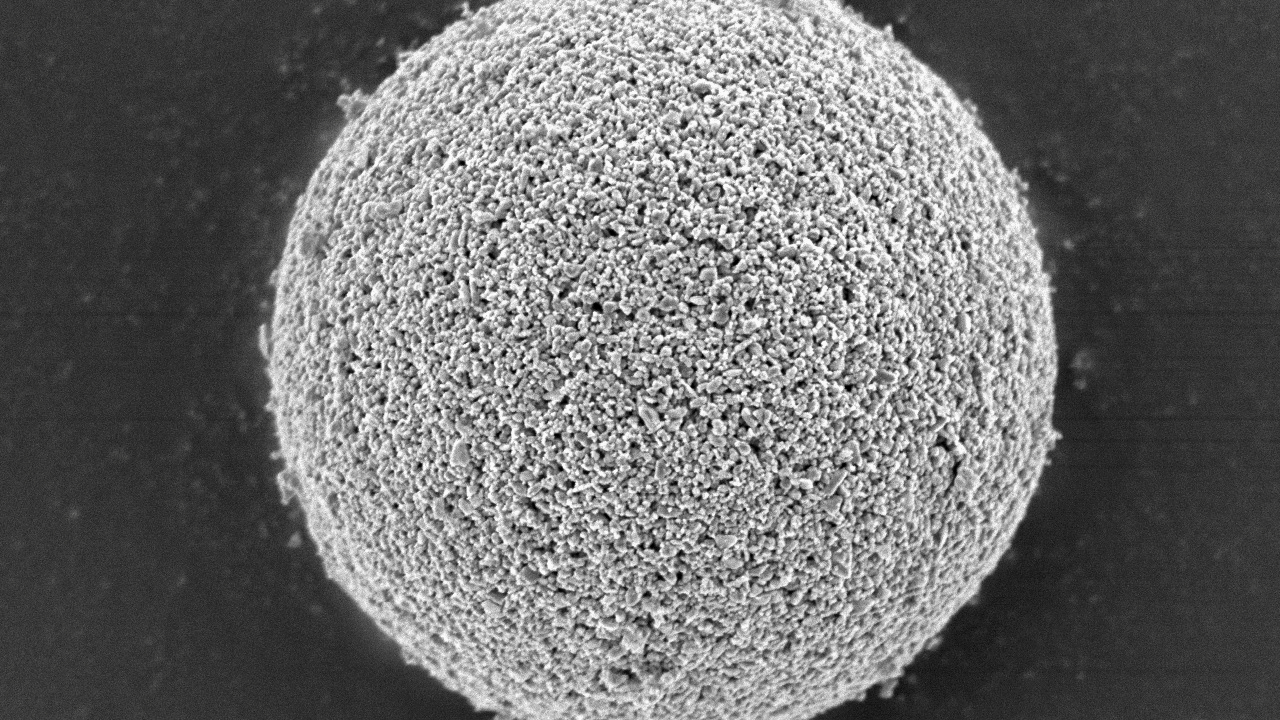

Granules produced by spray drying are spherical and have excellent fluidity, resulting in a sharper and more stable particle size distribution (PSD) than other drying methods. This makes it possible to produce granules with high fluidity that are easy to handle and fill into molds. In addition, by selecting the atomization method and conditions, it is possible to carry out precise particle formation design in terms of particle size, shape, density, etc. Particle size is controlled within the range of a single μm to approximately 200 μm. Reducing the particle size increases the specific surface area, but reduces handleability. Conversely, increasing the particle size decreases the specific surface area, but improves handleability. We use a variety of atomization technologies, including multiple patented technologies, to enable particle design tailored to your needs (Liquid Atomization).

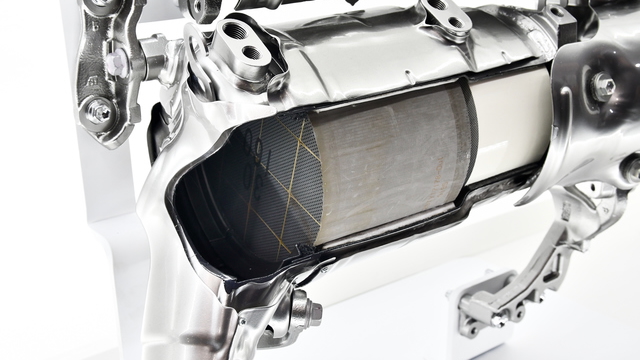

Spray dryers are also used to manufacture catalytic supports. Supports are the base material that fixes the catalyst components. Supports perform various functions, such as increasing the specific surface area and improving mechanical strength. Support materials include Al2O3, SiO2, CeO2, TiO2, ZrO2, zeolite, and activated carbon. Spray drying is used to produce a support as well as a mixture of the support and the active substance to be supported, depending on the application. Factors that determine the quality of a catalyst are activity and durability. The higher the catalytic activity, the less consumption and the easier controls. Furthermore, higher durability leads to a longer product life time. We perform various analyses and evaluations of the properties of catalyst powders obtained by spray drying.

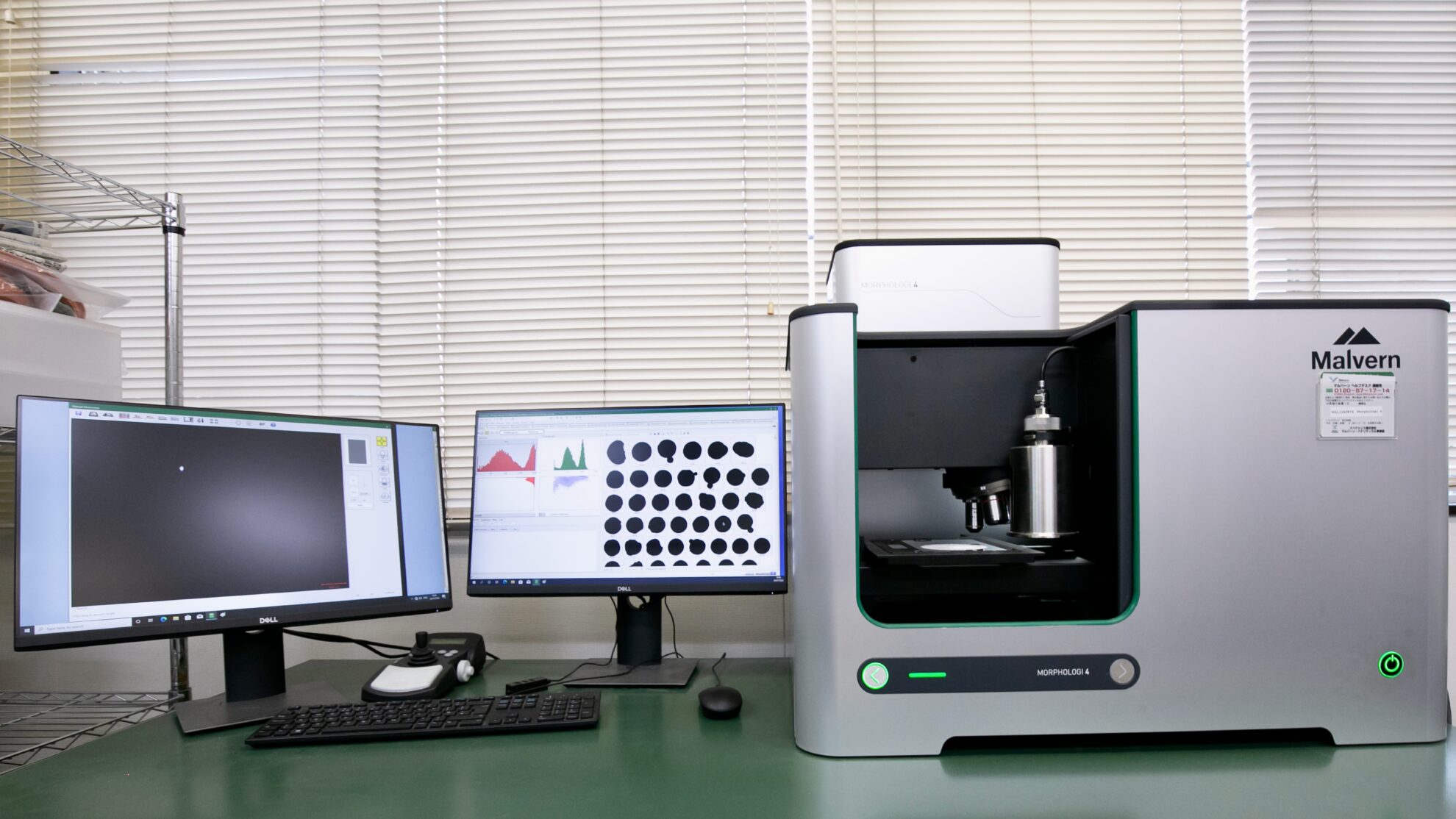

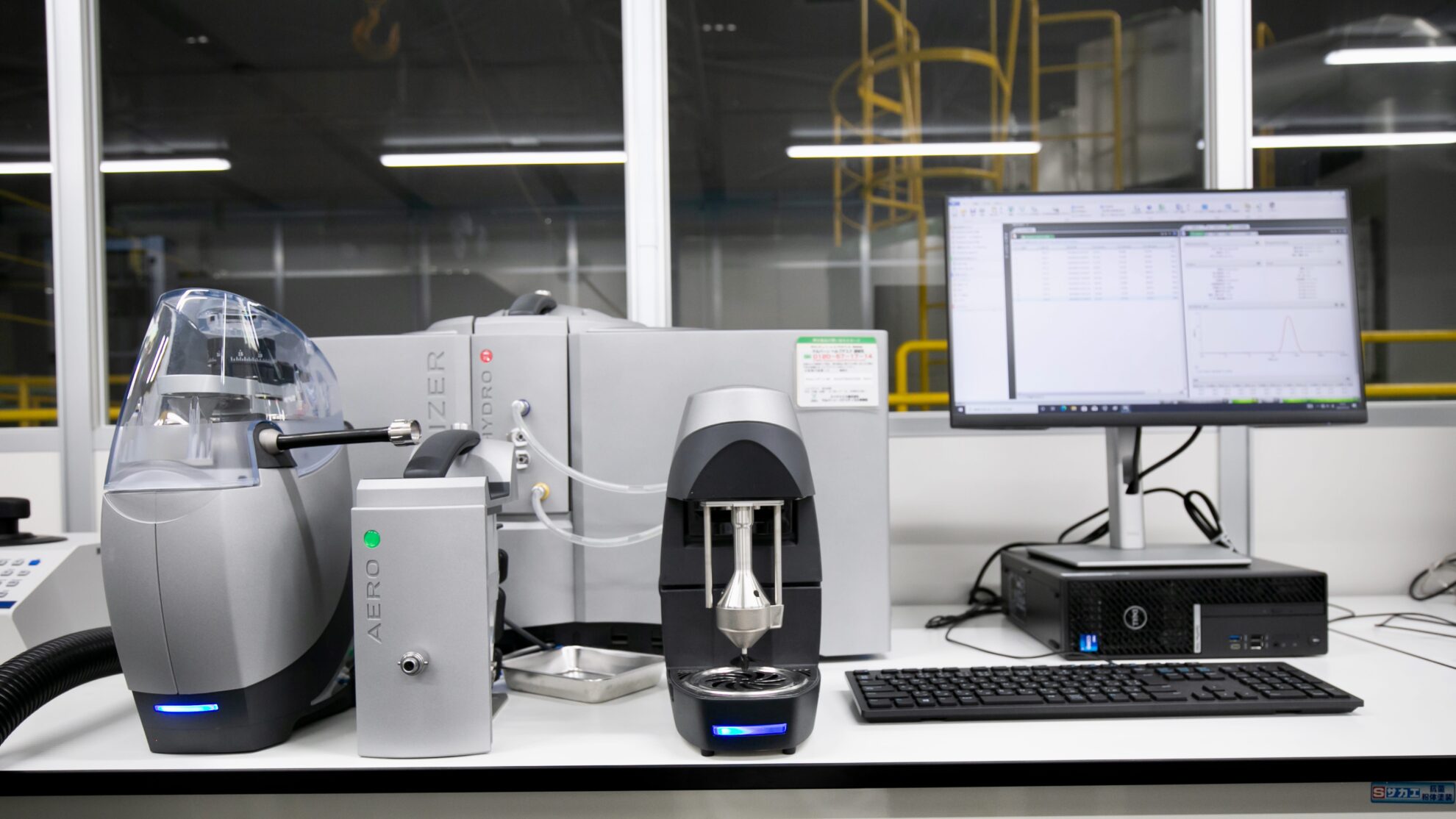

Particle size and shapes of granules are analyzed using multiple image analyzers and laser diffraction analyzers. Imaging analyzers can perform shape analysis such as particle size distribution and circularity, as well as brightness analysis of each individual particle. Online real-time laser diffraction PSD analyzer is also available to perform continuous particle size distribution analysis. SEM analysis can also be used to observe the surface of particles.

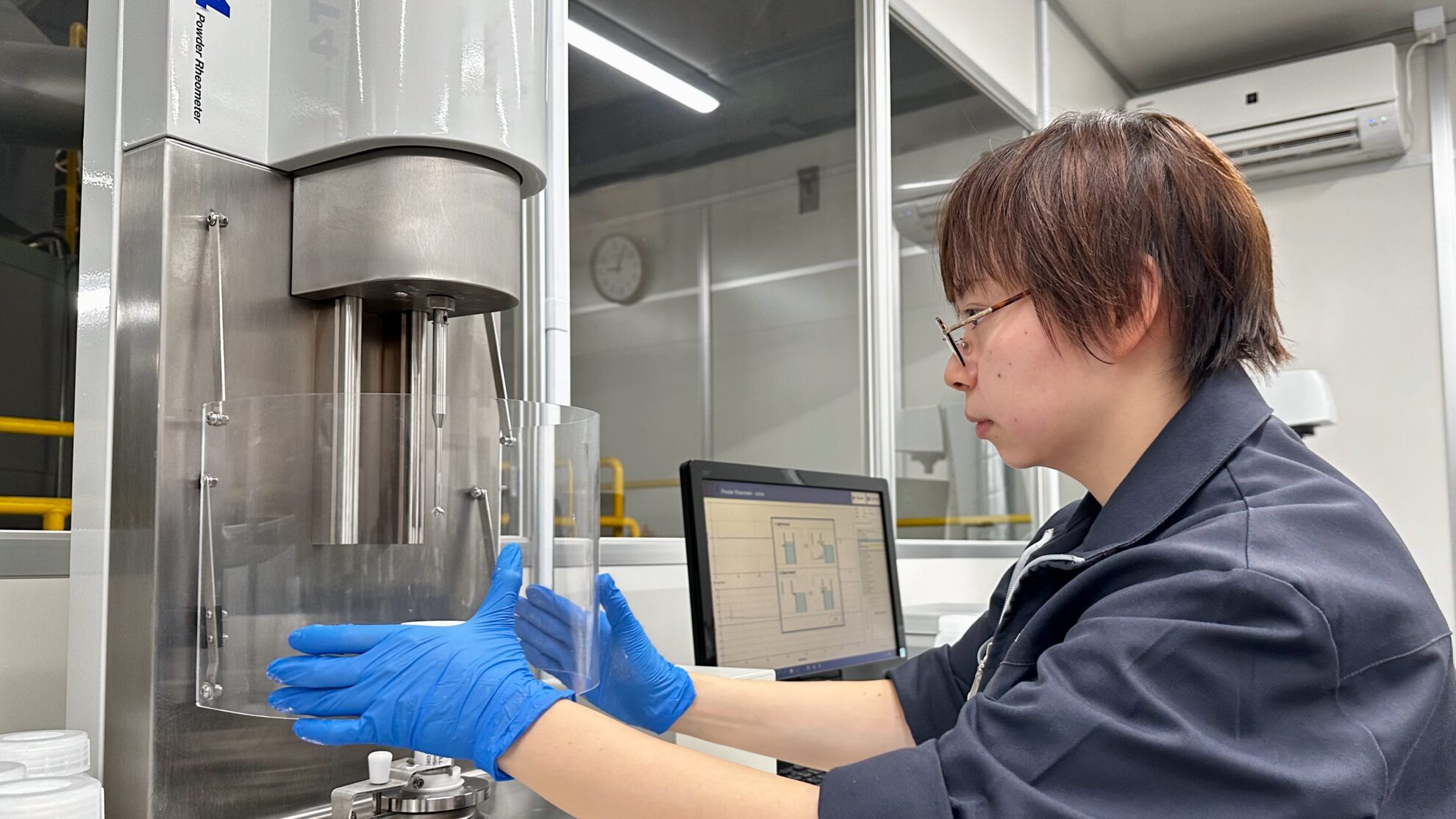

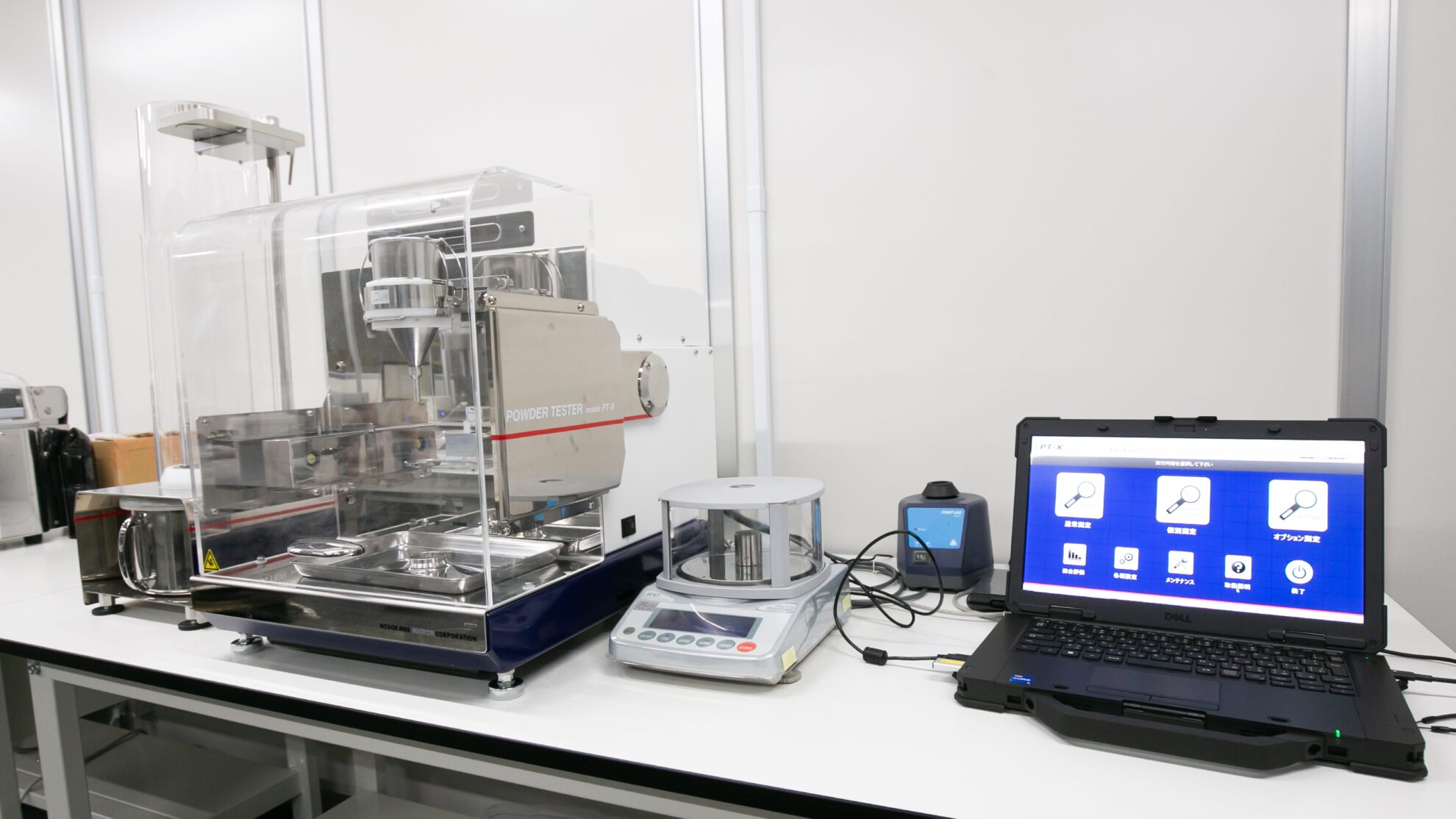

Powder characteristics analyzer and powder rheometer are used to analyze powder fluidity and flowability. In addition to the traditional methods of evaluating fluidity such as angle of repose, bulk density and Carr’s fluidity index, dynamic analysis is also available to measure the actual behavior of powders in a dynamic environment. Dynamic rheometer can also analyze the disintegration properties due to frictions among flowing particles, making it possible to evaluate filling and handling properties of powders.

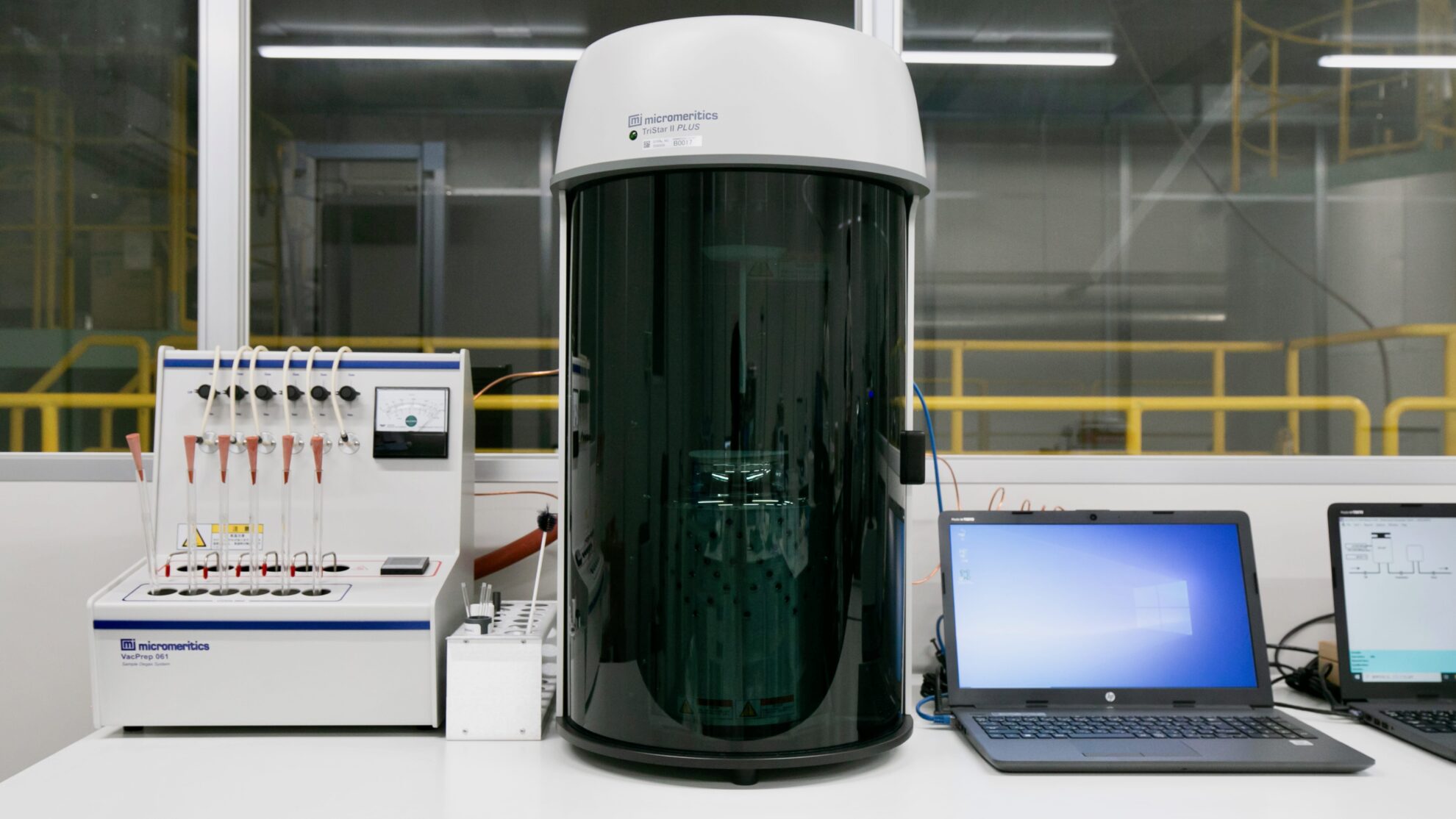

Analysis of specific surface area and density of particles is also important. We measure a specific surface area and pore distribution by constant volume method using gas adsorption. We also analyze true density and particle density by gas displacement method. Micro-particle crushing force measurement is also available to evaluate a particle strength by physically crushing a single particle.

Physical properties of liquid materials are also evaluated for parameters that affect the latter process: powder processing. In the case of slurries or suspensions, primary particle size distribution is measured using laser diffraction analysis. By circulating a liquid material and continuously measuring the particle size distribution, it is also possible to evaluate changes in cohesion, disintegration and re-dispersibility. We also perform rheology analysis using a wet rheometer for dynamic flow behavior such as viscoelasticity, shear stress, cohesive/dispersion stability, thixotropy and dilatancy properties, and yield point.

In this way, by evaluating powder properties from multiple angles, not just catalytic activity tests, it is possible to gain new discoveries and insights.

Our spray dryers have a proven track record in the spray drying process of catalysts. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Amorphous Solid Dispersions – Spray Drying and Freeze Granulation” and “Dispersibility of Nanofibers – Freeze Granulation of Cellulose Nanofibers (CNF) and Carbon Nanotubes (CNT)“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.