Flavors and spices are made by blending natural ingredients extracted from animals and plants with chemically synthesized compounds. Blended flavors and spices are widely used in foods and beverages, as well as cosmetics and pharmaceuticals.

Flavors and spices include a wide variety of plant-derived ingredients, such as citrus fruits like lemon, orange, and grapefruit, mint, menthol, cinnamon, vanilla, coffee, tea, and fragrant wood. Spices in particular are used to enhance flavors and also to eliminate or mask odors. A wide variety of ingredients are used, including traditional Japanese spices such as wasabi, ginger, shiso, yuzu, as well as pepper, chili pepper, garlic, nutmeg, curry, turmeric, paprika, cardamom, and herbs such as basil, coriander, lemongrass, and rosemary. There are also a variety of seasoning products that combine these ingredients with other seasonings. In recent years, there has also been development in aroma chemicals, which blend these ingredients to develop new flavors.

The main roles of flavors and spices are:

Flavor addition: Adding fragrance to unscented or lightly scented ingredients

Flavor replenishment: Replenishing the fragrance of ingredients that have lost or lost their aroma

Odor masking: Masking and correcting undesirable odors

These flavors and spices are available in water-soluble, oil-soluble, and emulsified liquid and powder forms. Powders have a smaller mass and volume than liquids, which helps reduce transportation costs. In addition, because they are dry products, they can be stored for a long period of time.

Emulsified functional oils and plant extracts are spray-dried by adding excipients to flavors and core materials. In addition to preserving flavor, dried products must also meet quality requirements such as ingredient homogeneity, stability, solubility, and sustained release. When adding low-molecular-weight ingredients such as monosaccharides including fructose, oligosaccharides, and amino acids, it is necessary to prevent thermal degradation. Compared to other drying processes, spray dryers are said to have a shorter drying time and less thermal impact. However, if there is a concern about thermal denaturation of the material, it is necessary to appropriately set the operating conditions of the spray dryer, such as the drying temperature and process gas volume.

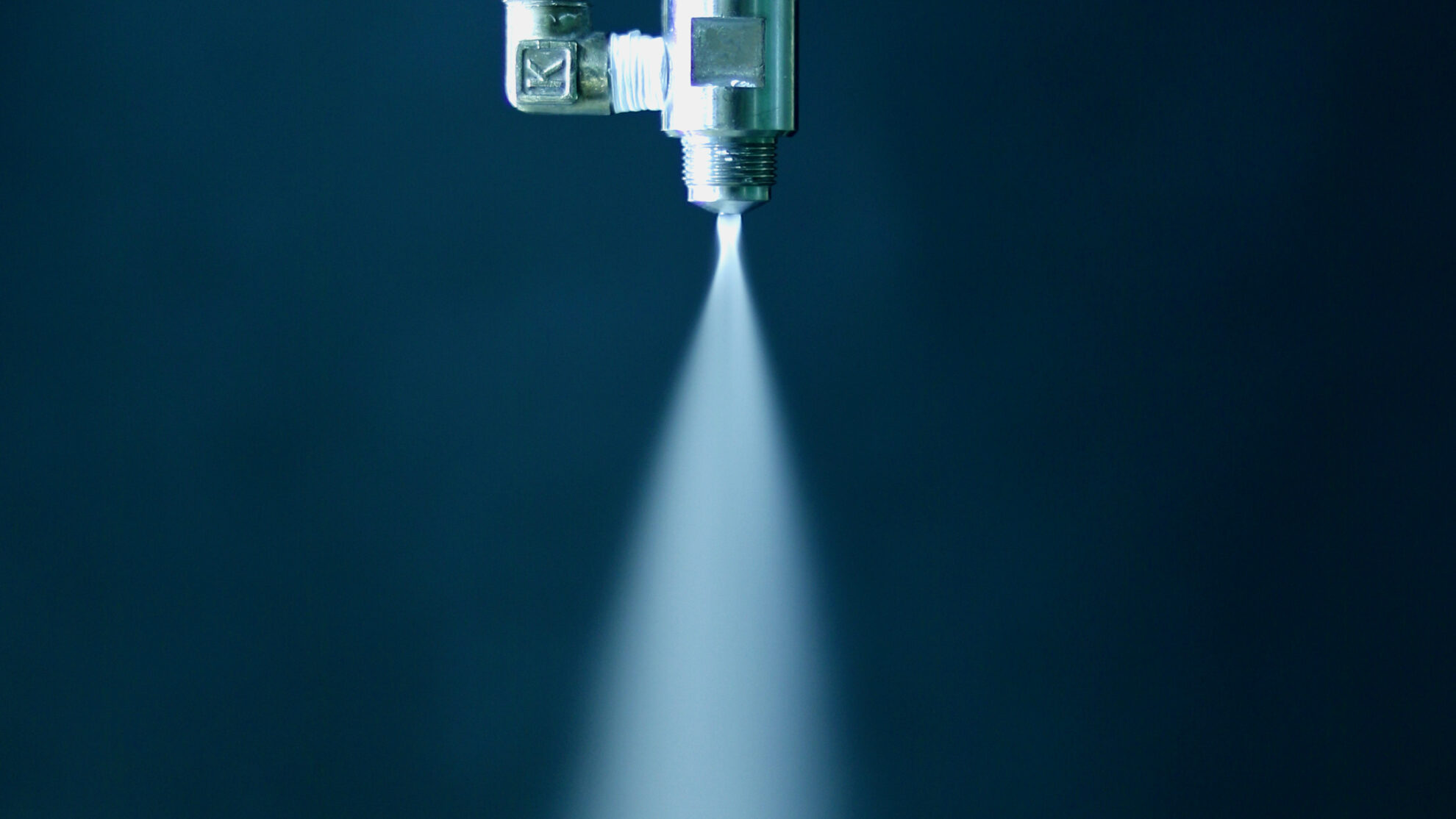

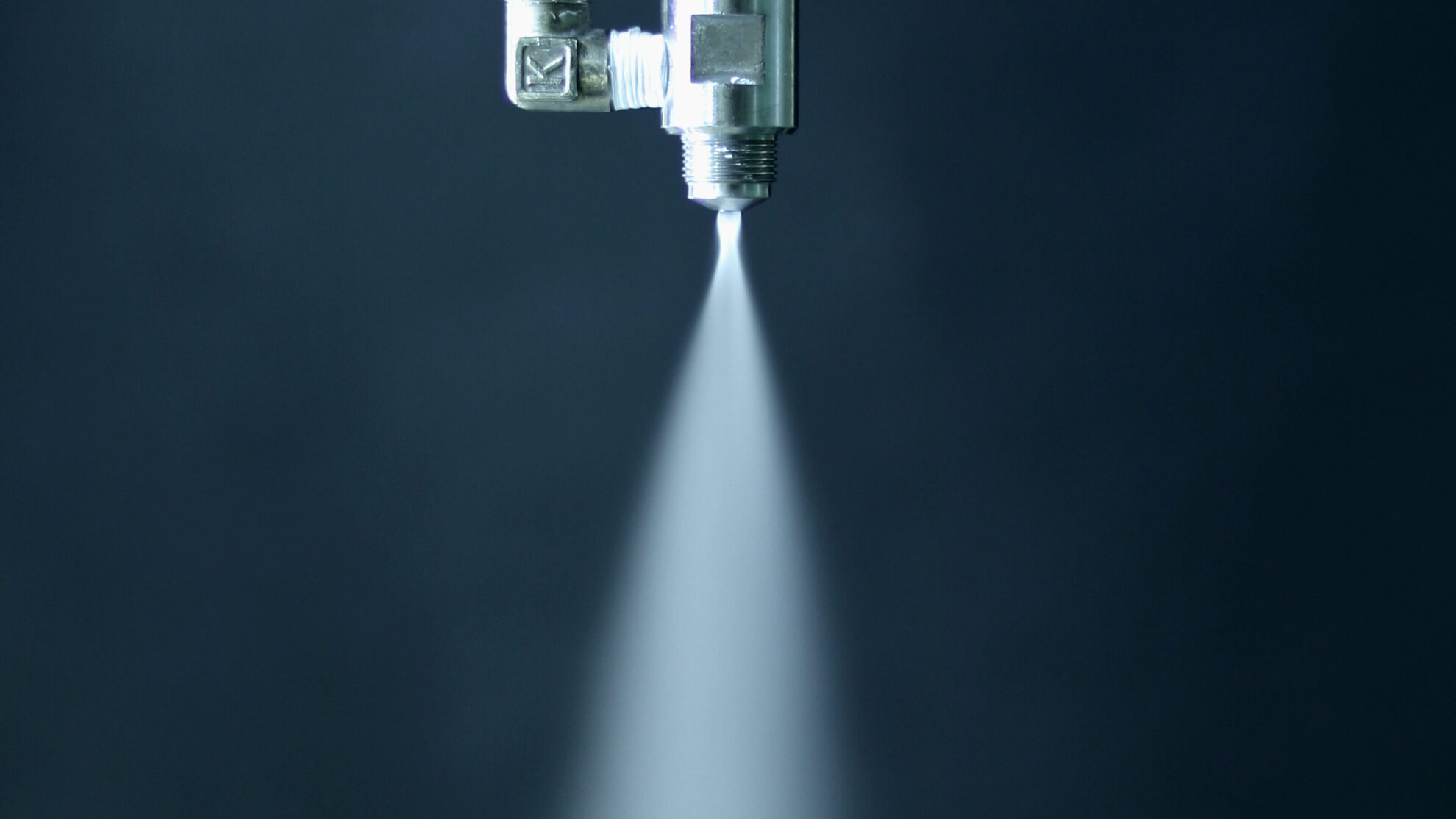

Spray drying of flavors and spices is generally performed at a low drying temperature for gentle drying. Under low temperature operating conditions, the liquid dries slowly, which tends to result in a higher bulk density. On the other hand, under high temperature conditions, the droplets dry in a short time, which accelerates the formation of particle shells. This can cause particles to expand, burst, or become hollow due to internal evaporation. The moisture content is higher under low temperature conditions and lower under high temperature conditions. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. When selecting an atomization method, not only the droplet size but also the effects of physical contact and friction must be taken into consideration.

When the product contains a large amount of highly hygroscopic ingredients or deliquescent ingredients such as citric acid, it is necessary to design the spray drying process to properly prevent product adhesion. Specifically, dehumidified air is introduced into all or part of the process gas. In addition, air sweeper or dehumidifying air line may be installed in the drying chamber. It is also important to appropriately set the temperature and humidity of the powder recovery line. For example, the powder quality may be kept constant at the time of product collection by optimizing the temperature of dehumidified air as well as the powder transportation distance through the powder conveying line. In addition to adjusting the raw material with additives, oxidation can also be prevented from a process perspective by using inert gas as the process gas for the spray dryer.

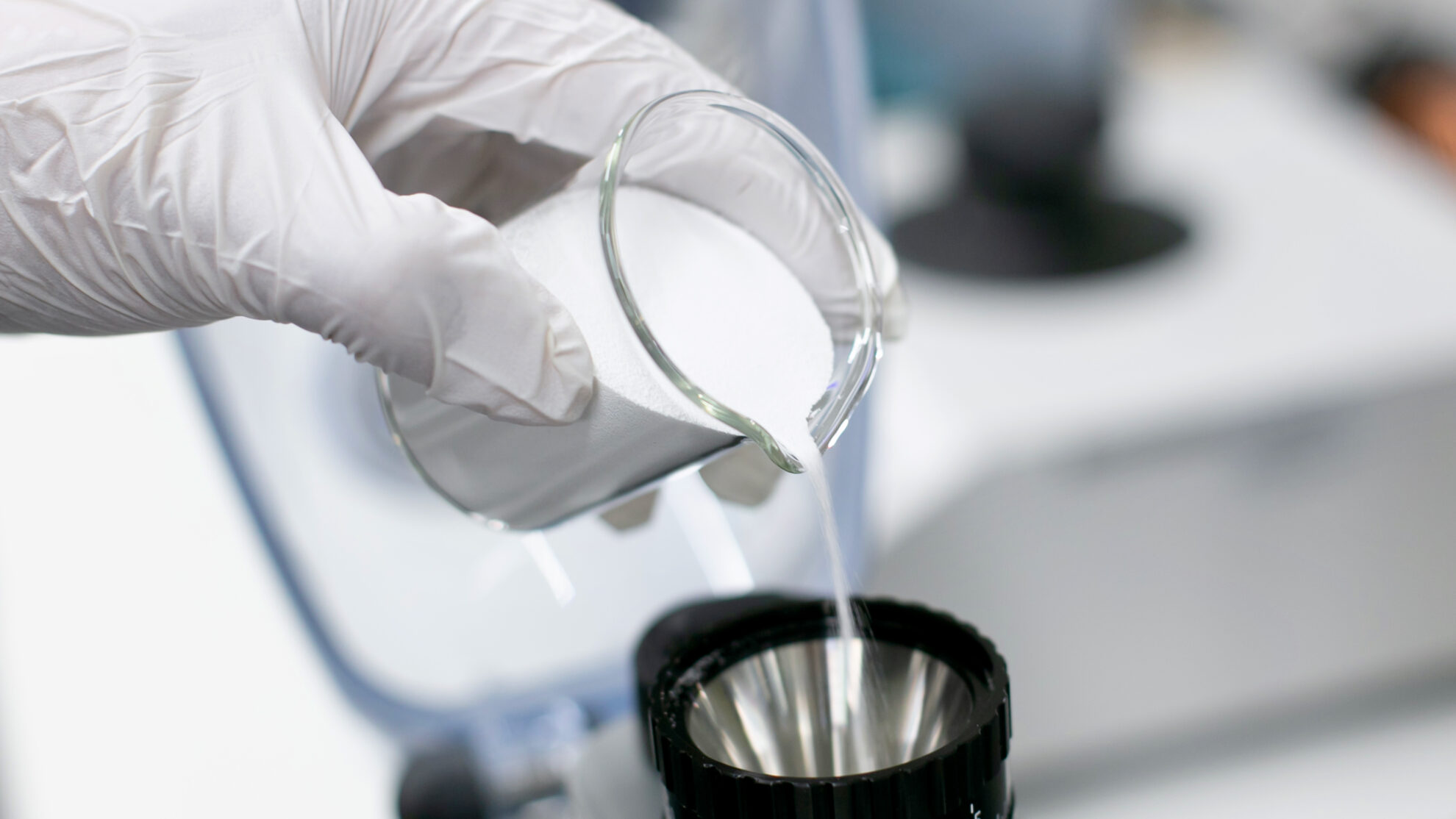

For raw materials, the concentration, presence or absence of additives, and the amount of additives added are key indicators. Increasing the concentration of the raw material reduces the amount of water that evaporates per unit time, thereby improving production efficiency. However, the concentration of the raw material affects the particle size and density of the product, so an appropriate value must be determined. By adjusting the type and the amount of additives, we control the residual rate of flavor components, the solubility of the powder, etc. Trehalose and cyclodextrin, a cyclic oligosaccharide, may also be added to mask or stabilize specific components and improve flavor.

Volatile components usually have low boiling points and evaporate during spray drying, but adding maltodextrin, cyclodextrin, oligosaccharides, etc. makes it possible to retain the components. For example, cyclodextrin can encapsulate the molecules of volatile components within its hydrophobic cavity, reducing the loss of components during spray drying. This is effective in slowing the release of flavor components in products. Similarly, by adding an appropriate concentration of coating additives and spray drying at lower temperature, it is possible to produce powders containing alcohol, such as powdered alcohol, that retain a high residual alcohol content. When high-quality powdered alcohol is redissolved in water, it is possible to restore not only the alcohol but also the flavor of the liquid alcohol.

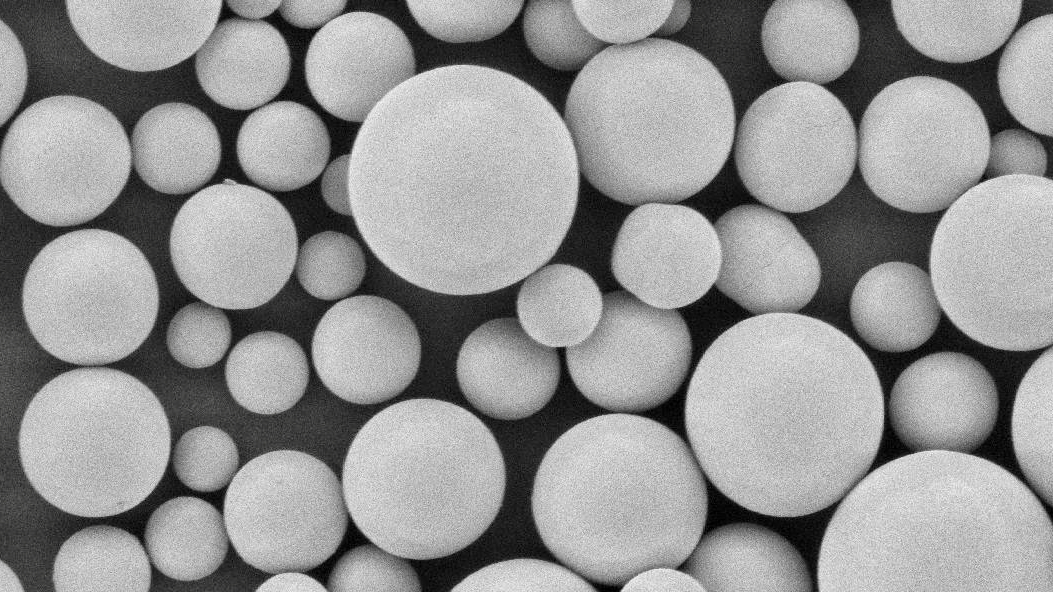

In general, spray drying involves the evaporation of the solvent from the droplet surface, and the movement of moisture from the droplet to the surface, causing the entire droplet to shrink. At the same time as the moisture moves, the solid content within the droplet moves outward, forming a particle structure. As a result, the particles tend to have a high density outer shell and a low density or hollow interior. Furthermore, in suspensions, if there are multiple particle components contained in the liquid and each particle has a different particle size and density, segregation may occur inside the granules due to particle movement during drying. It is important to understand the physical properties of the raw materials, particle size, density, internal structure, etc. of the dried particles, and then to control the operating conditions appropriately.

The main parameters for quality control of powder products are the residual rate of flavor components, color, particle size distribution, bulk density, and moisture content. In addition, flowability, wettability, solubility, color, and particle surface properties related to taste may also be included. Regarding particle size, larger particles have good flowability and are easy to fill into containers, so they have a high bulk density. The opposite is true for small particles, which have a low bulk density. If the bulk density value is unstable, the stability during product filling will decrease. Large particles have a small specific surface area, which means that moisture does not escape easily during drying, and the moisture content tends to be high. Small particles have a large specific surface area, which means that moisture escapes easily, resulting in a low moisture content. On the other hand, highly hygroscopic powders may re-absorb moisture contained in the exhaust air, resulting in small particles with a high moisture content and large particles with a low moisture content.

Our spray dryers have a proven track record in the spray drying process of flavors and spices. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

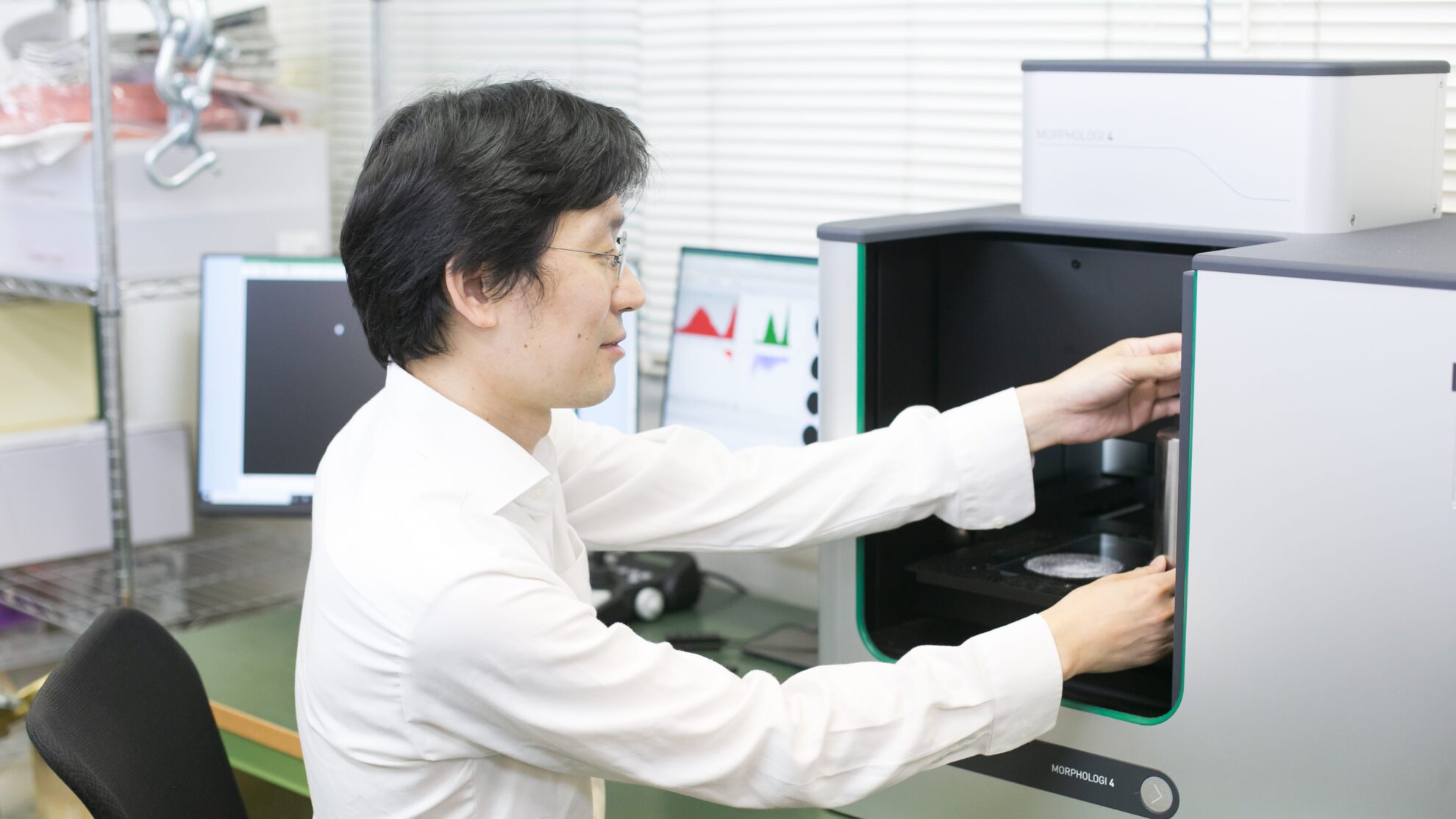

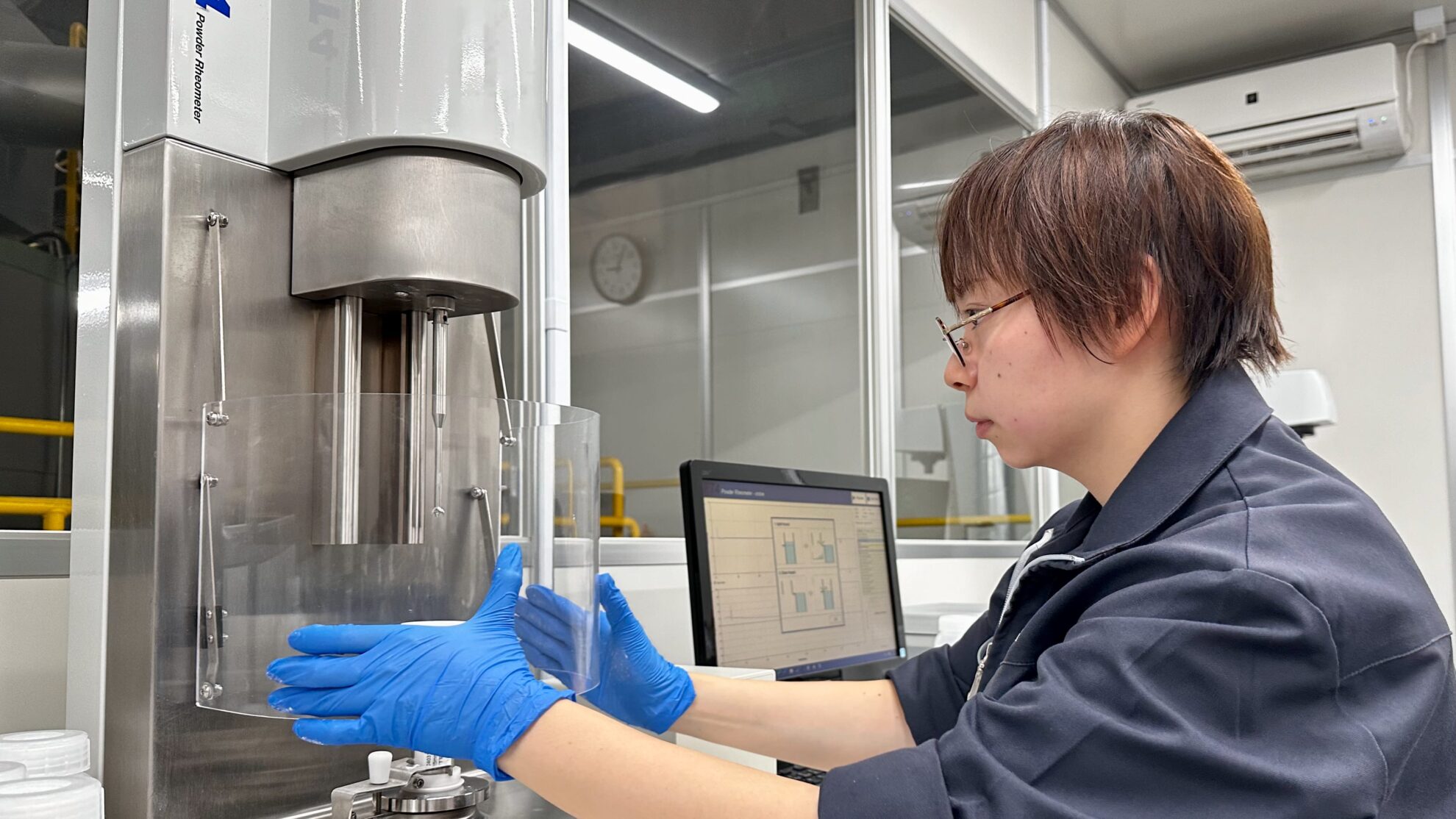

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.