Algae refers to organisms that perform oxygen-producing photosynthesis, excluding mosses, ferns, and seed plants. Among these, in addition to those that can be seen with the naked eye, such as wakame seaweed, kelp, green laver, and sea grapes, there are also tiny phytoplankton called microalgae, which are about 1 μm to 1 mm in size. Microalgae are basically single-celled organisms that produce about half of the oxygen in the Earth’s atmosphere through photosynthesis. It is said that there are several million species of microalgae, including those that have yet to be discovered.

Microalgae are said to be the foundation of the aquatic food chain, providing nutrients to higher-level organisms. Their bodies are rich in lipids, carbohydrates, proteins, vitamins, minerals, dietary fiber, and more. Microalgae such as Chlorella, Spirulina, Euglena, Labyrinthula, and Dunaliella are commercially used as functional foods by extracting the useful components contained within their bodies. The red astaxanthin synthesized in the body from Haematococcus has UV protection and antioxidant properties, and is believed to be effective in fatigue recovery and anti-aging, and is used in cosmetics and supplements. In addition to food and supplements, microalgae are also used in livestock feed, fertilizer, soil conditioners, coloring agents, etc. Microalgae are also recognized as a promising alternative energy source for biofuels. Some algal biomass has a high lipid content. Because of its high carbon dioxide fixation capacity and excellent growth rate, it is expected to be a promising source of next-generation environmentally friendly fuels, such as sustainable aviation fuel (SAF) and renewable diesel (RD), which are primarily suitable for transportation applications such as aircraft and automobiles.

The Algae Research Unit at the University of Tsukuba is conducting research into biofuels made from Botryococcus braunii, Aurantiochytrium, and other organisms. Aurantiochytrium is a heterotrophic organism that does not photosynthesize, so it does not fall under the definition of algae. However, a research group led by Professor Makoto Watanabe of the University of Tsukuba presented a paper on this technology at the First Asia-Oceania Algae Innovation Summit, held at the University of Tsukuba in December 2010. Aurantiochytrium has a high oil production efficiency, producing oil by absorbing surrounding organic matter. This characteristic makes it possible to produce oil in two stages while purifying water by adding Aurantiochytrium to the primary treated organic wastewater, and then using Botryococcus to produce oil through photosynthesis in the secondary treated water after oil extraction. The residue after oil extraction can also be used for methane fermentation or as livestock feed. In April 2023, as part of a project to develop bio-based production technologies to accelerate the realization of carbon recycling, led by the New Energy and Industrial Technology Development Organization (NEDO), a national research and development agency, NEDO succeeded in creating the world’s first microalgae that produces oil, a fuel substance, outside its cells without introducing foreign genes. By enhancing the expression of specific genes in the cyanobacterium Synechococcus elongatus PCC 7942 strain, they succeeded in efficiently producing free fatty acids, a fuel substance, outside the cell. Taisei Corporation and other project members plan to further improve production capacity and will build and conduct demonstration tests of an algae biofuel production system.

Biofuels derived from microalgae hold great potential, but to put them to practical use, they must be commercially viable at production costs, so there is a need to improve production efficiency and reduce manufacturing costs by establishing mass cultivation production technology. In addition to biofuels, it is also important to maximize the added value of microalgae as a raw material by making full use of the useful components produced by microalgae in fields other than biofuels, such as food and pharmaceuticals. For example, our customer, Euglena, is operating a demonstration plant to commercialize domestically produced renewable jet and diesel fuels in cooperation with Yokohama City, Chiyoda Corporation, Itochu Enex, Isuzu Motors, and ANA Holdings, while also developing a variety of products in the healthcare field, including food and cosmetics. OP Bio Factory collects marine biological resources, searches for compounds and functionality, and conducts research and development, and uses the microalgae Pavlova discovered from its own library to develop the high-value-added product “Pavlova,” which is rich in fucoxanthin, EPA, DHA, GABA, etc. At the Okinawa Life Science Research Center, where its headquarters are located, OP Bio Factory uses our bioshakers in the cultivation process of isolated microorganisms and our spray dryers in the microalgae powderization process.

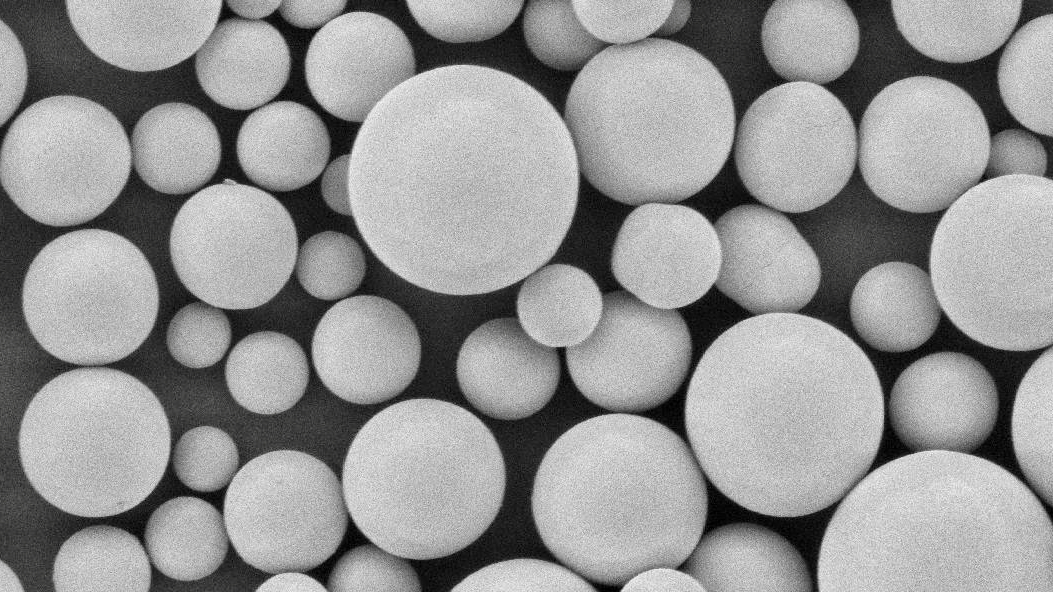

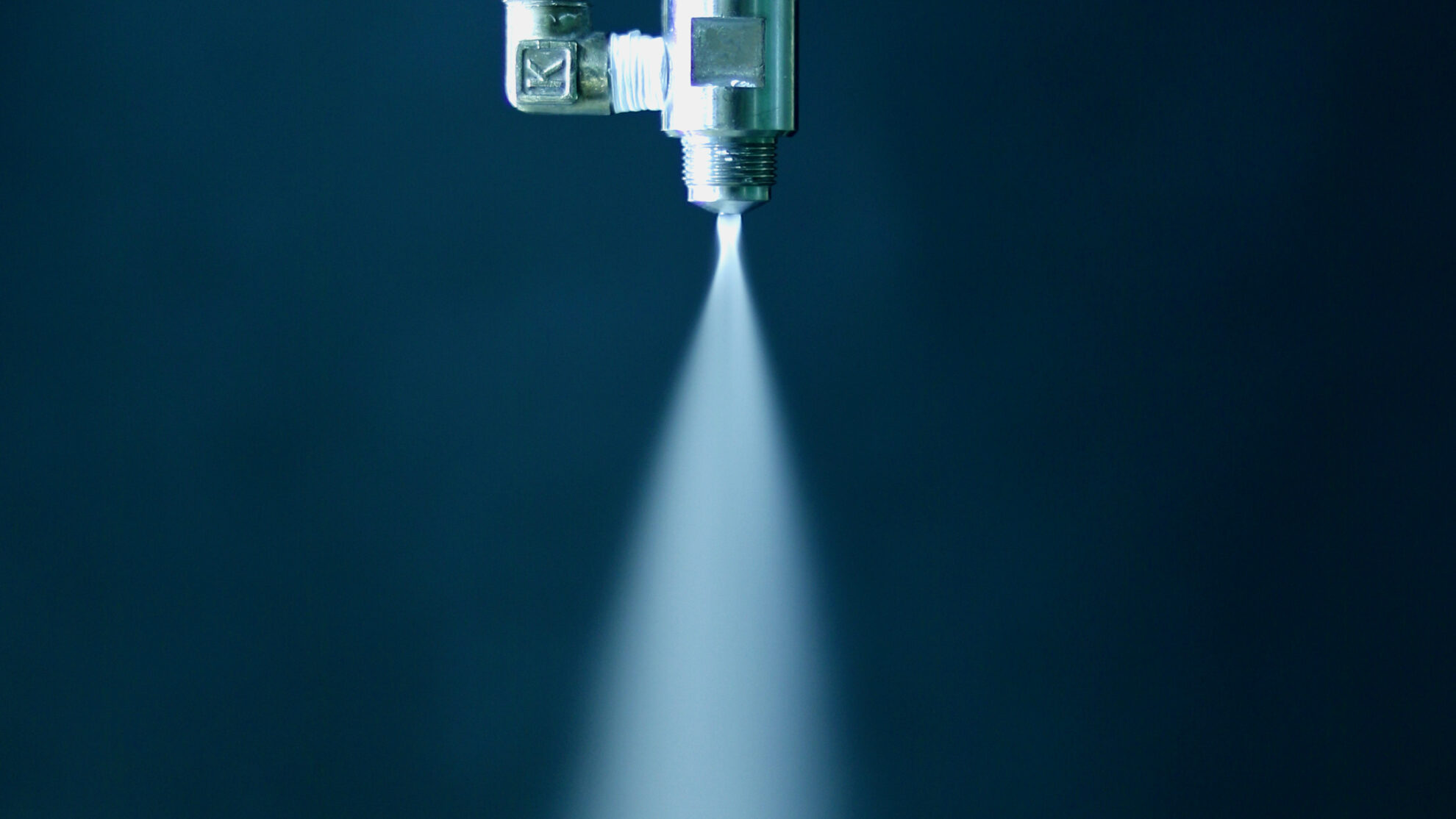

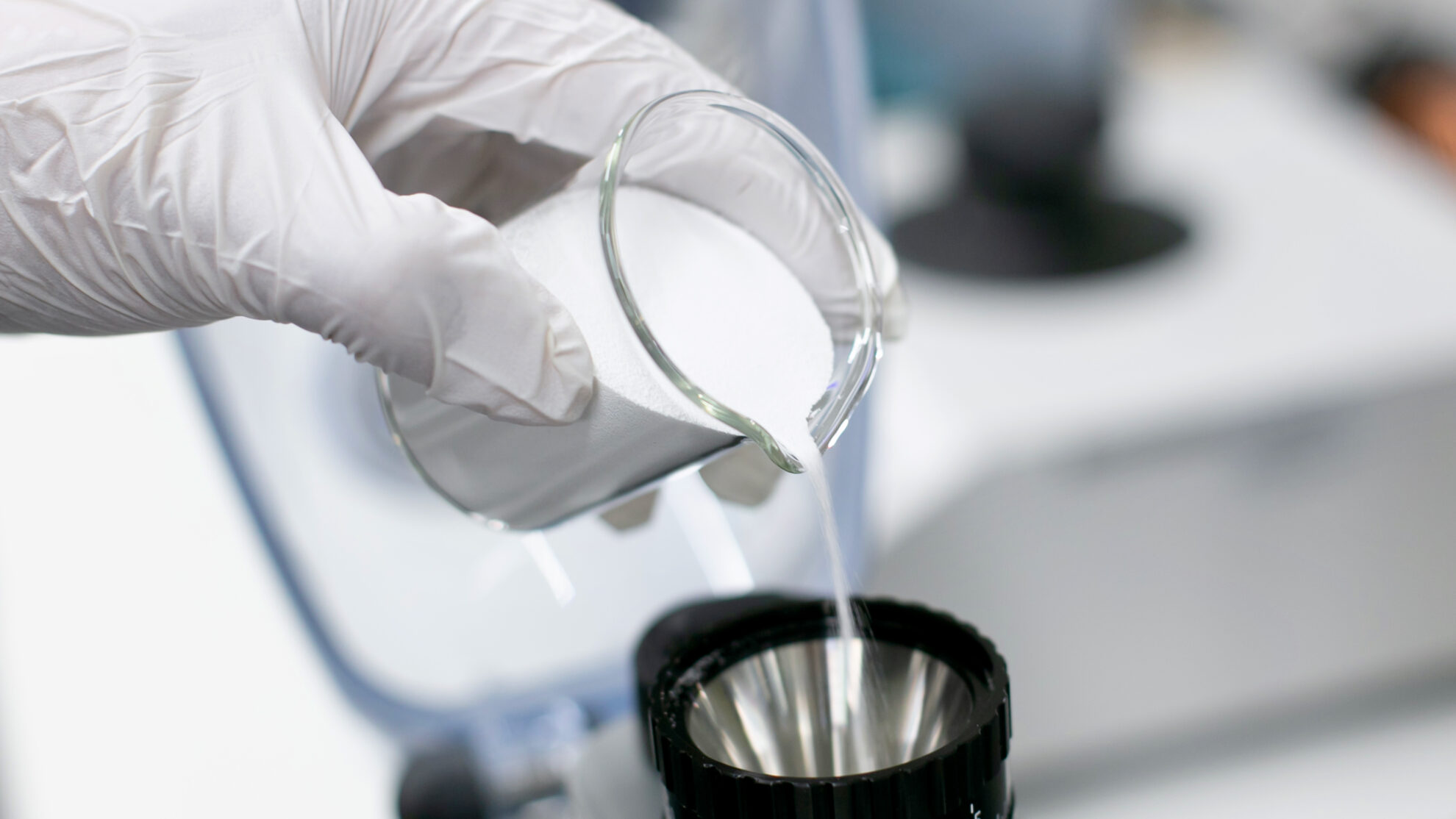

The microalgae production process begins with cultivation. The cultivation process can be carried out in an open system outdoors or in a closed system using a photobioreactor. The cultivated algae is then harvested and refined through concentration, filtration, and extraction processes. After purification, the algae is processed according to its intended use, resulting in final products such as biofuel, food, cosmetics, pharmaceuticals, and bioplastics. Spray dryers are used in the drying process of microalgae. By powdering the useful components produced by microalgae, it is expected that their use will be further expanded in fields such as food, pharmaceuticals, cosmetics, feed, and fertilizer. Carotenoids and lectins are also considered promising research targets in the field of drug discovery.

Our spray dryers have been delivered to many major Japanese companies for use in the drying process of microalgae, including the Algae Industry Creation Consortium, chaired by Professor Makoto Watanabe of the University of Tsukuba. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.