Collagen is a protein found outside animal cells. In the human body, it accounts for about 30% of all protein. It exists as a fibrous protein that fills the gaps between cells, and plays an important role in providing elasticity and other functions in many tissues, including skin, hair, internal organs, bones, tendons, and eyes. Collagen is repeatedly broken down and synthesized in the human body. As we age, synthesis decreases, which can lead to sagging skin and pain in the joints and tendons. For this reason, it is said that taking collagen and promoting synthesis can stimulate metabolism.

Collagen peptides are high-purity proteins made by enzymatically breaking down collagen into smaller molecules. Unlike collagen and gelatin, they dissolve easily in cold water and do not harden or gel when cooled down. In addition, because it is tasteless and odorless, it is widely used as a stabilizer and excipient for food and pharmaceuticals, as well as in cosmetics, supplements, beverages, etc. The collagen peptide market is expected to grow at a rate of 7% per year, reaching approximately US$2 billion in 2035.

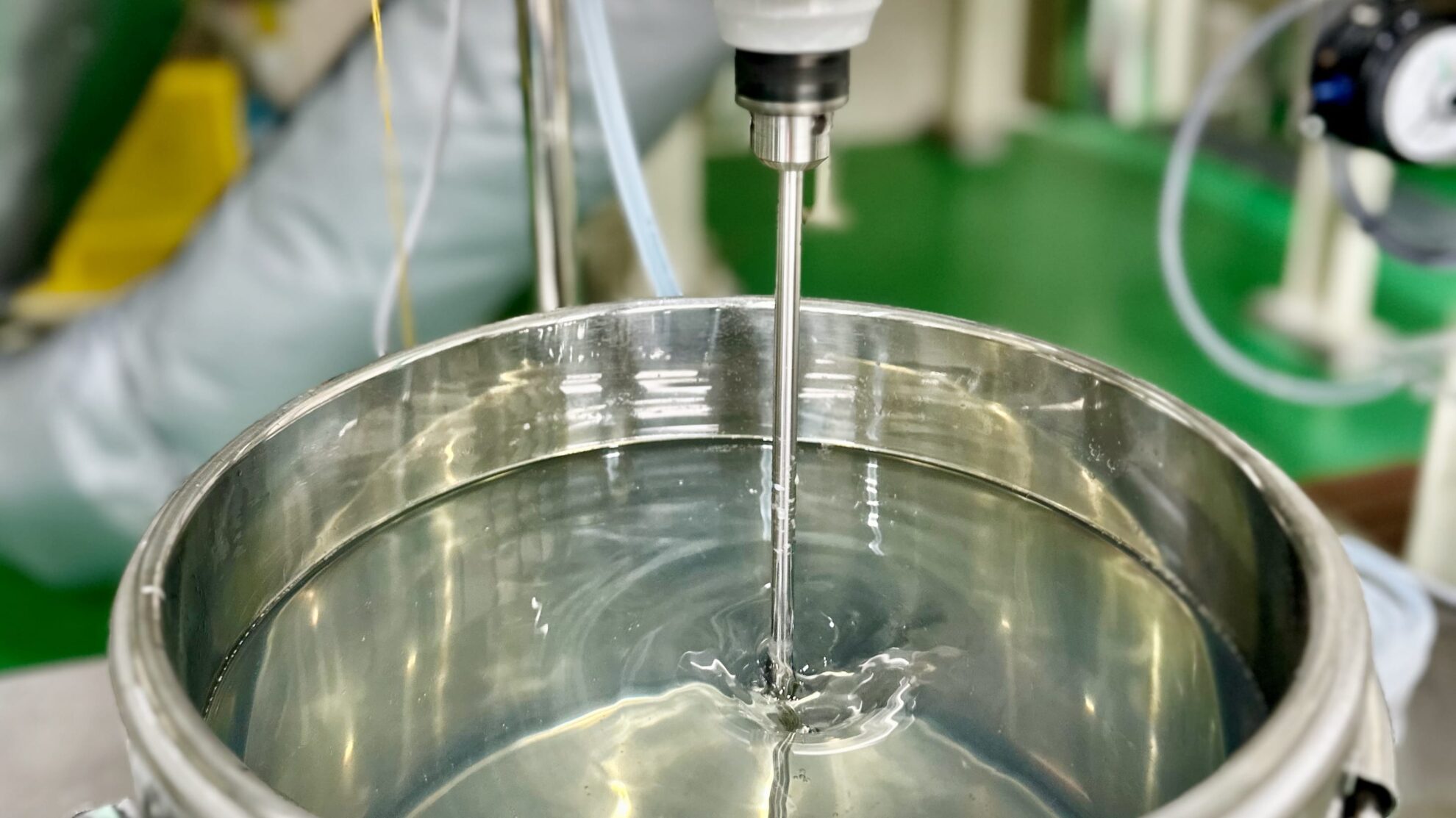

The collagen peptide powder manufacturing process involves pre-treatment, extraction, enzymatic hydrolysis, filtration, concentration, sterilization, and then drying and granulation of the raw materials. The raw materials are mainly skin, bone, and cartilage from cows, pigs, chickens, and fish, and are classified into types I to V depending on the part and type of animal they are found in. Since the physical properties vary depending on the type and part of the raw material, the production operating conditions are adjusted during the manufacturing process depending on the quality of the raw materials and the final product.

A properly designed spray dryer is required for the spray drying of collagen peptides. If the spray drying process is not properly designed, problems such as a decrease in product recovery rate due to the dried product adhering to the process, powder agglomeration, or re-absorption of moisture contained in the process exhaust may occur. To achieve highly efficient and stable production, it is important to design an appropriate spray drying process by taking into consideration the raw materials, process flow, operating conditions, and the quality of the final powder product.

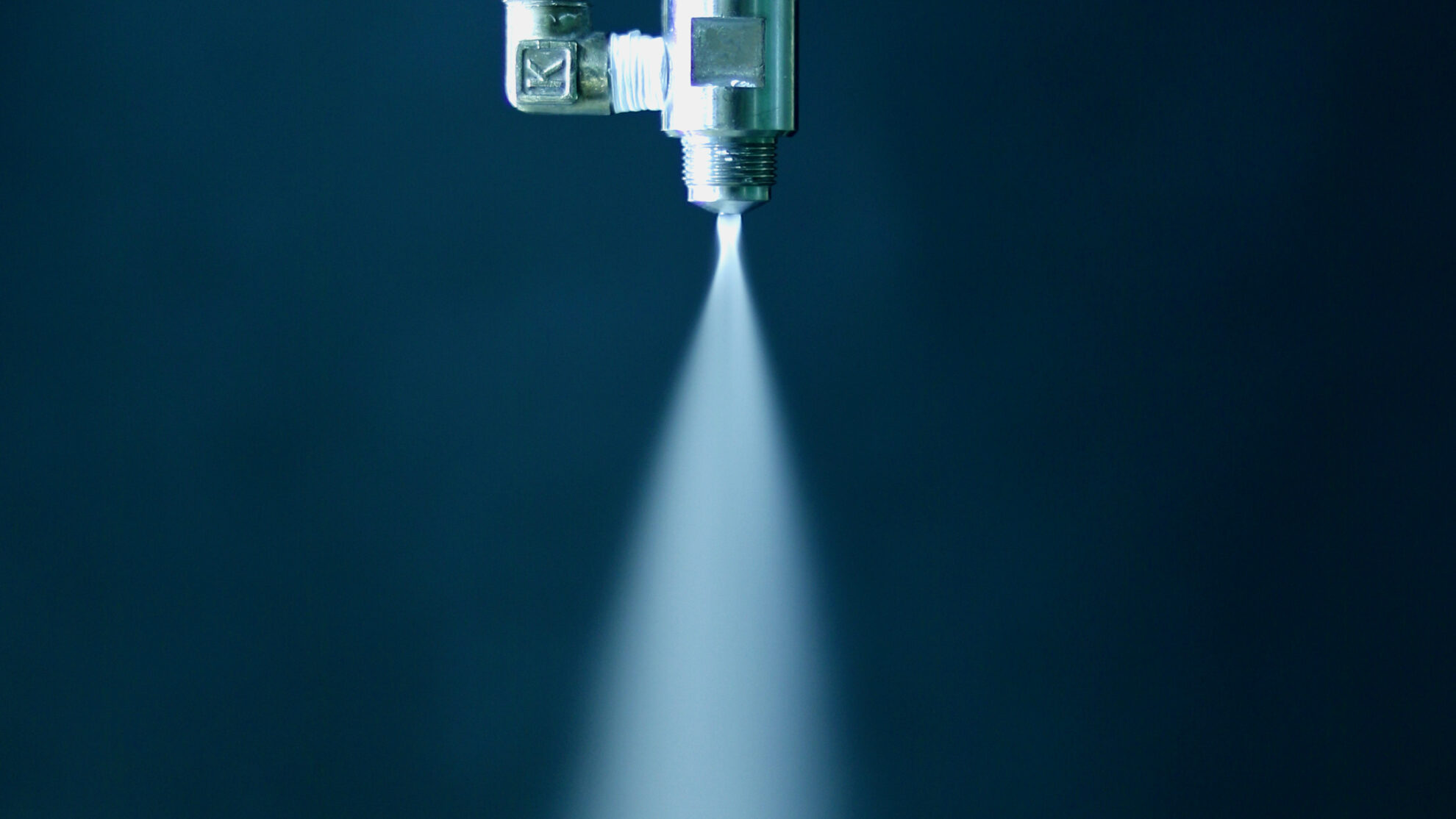

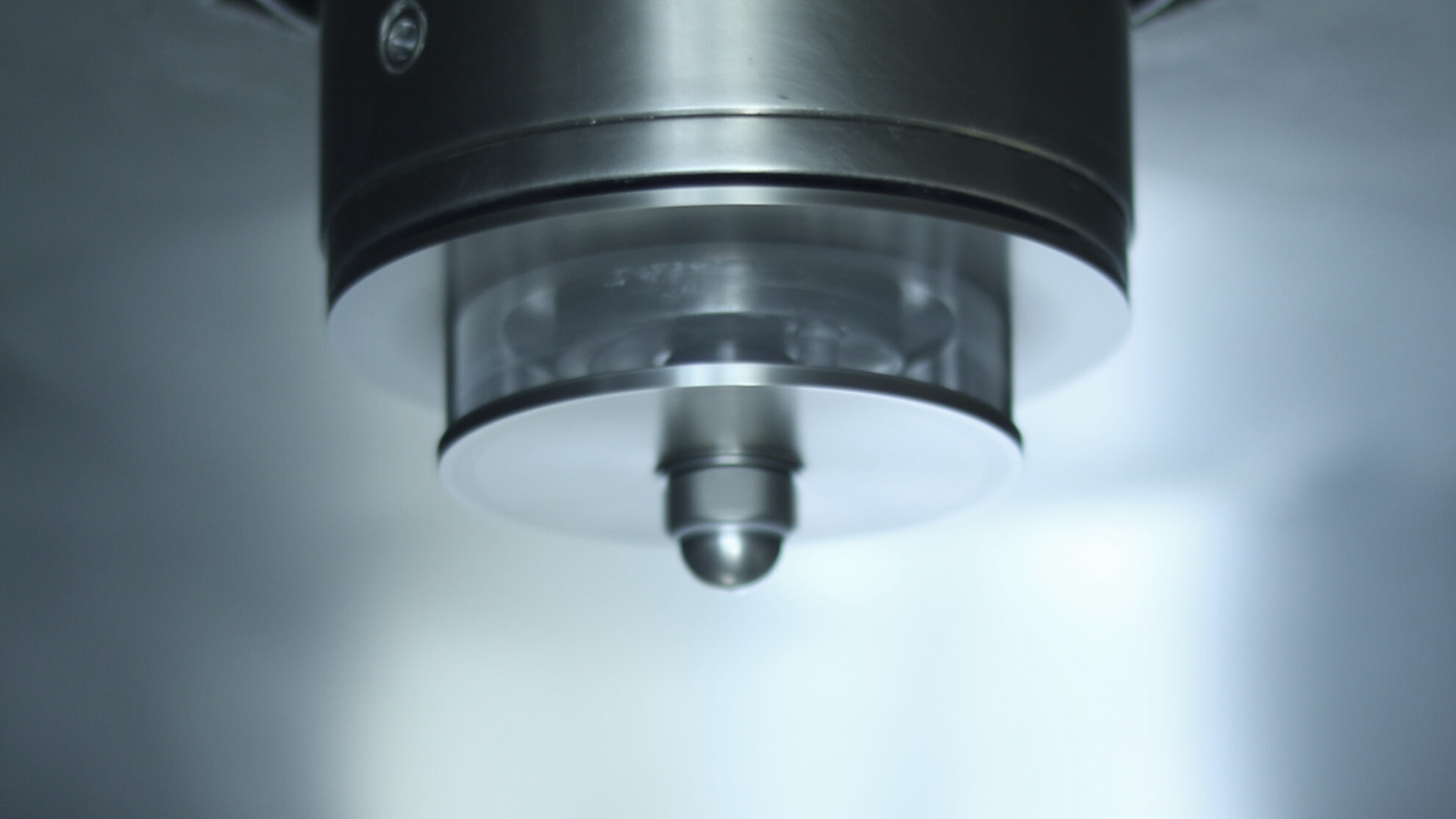

Spray drying of collagen peptides is generally performed at a low drying temperature for gentle drying. Under low temperature operating conditions, the liquid dries slowly, which tends to result in a higher bulk density. On the other hand, under high temperature conditions, the droplets dry in a short time, which accelerates the formation of particle shells. This can cause particles to expand, burst, or become hollow due to internal evaporation. The moisture content is higher under low temperature conditions and lower under high temperature conditions. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. When selecting an atomization method, not only the droplet size but also the effects of physical contact and friction must be taken into consideration.

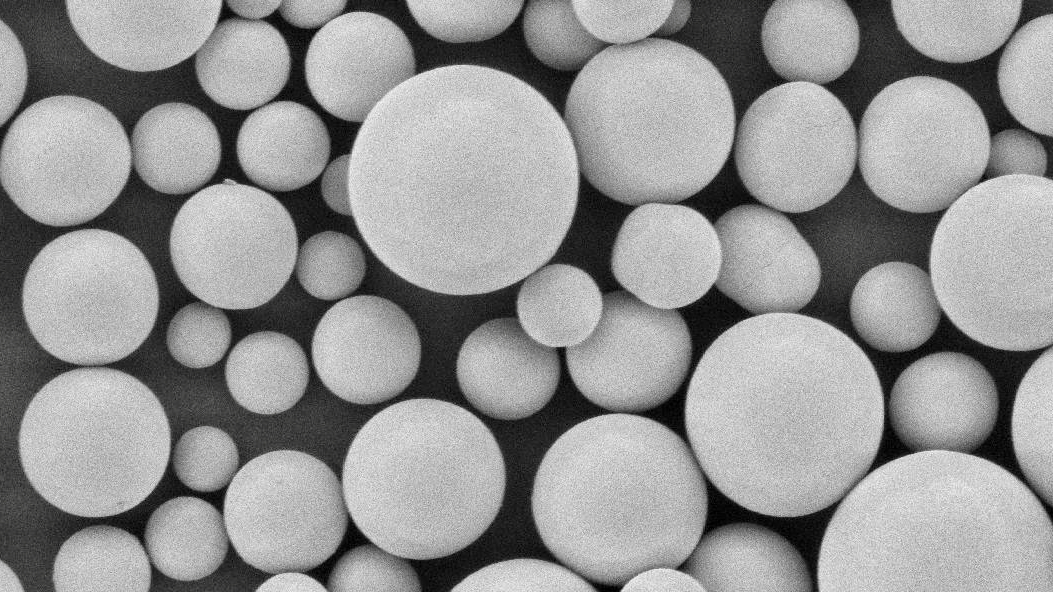

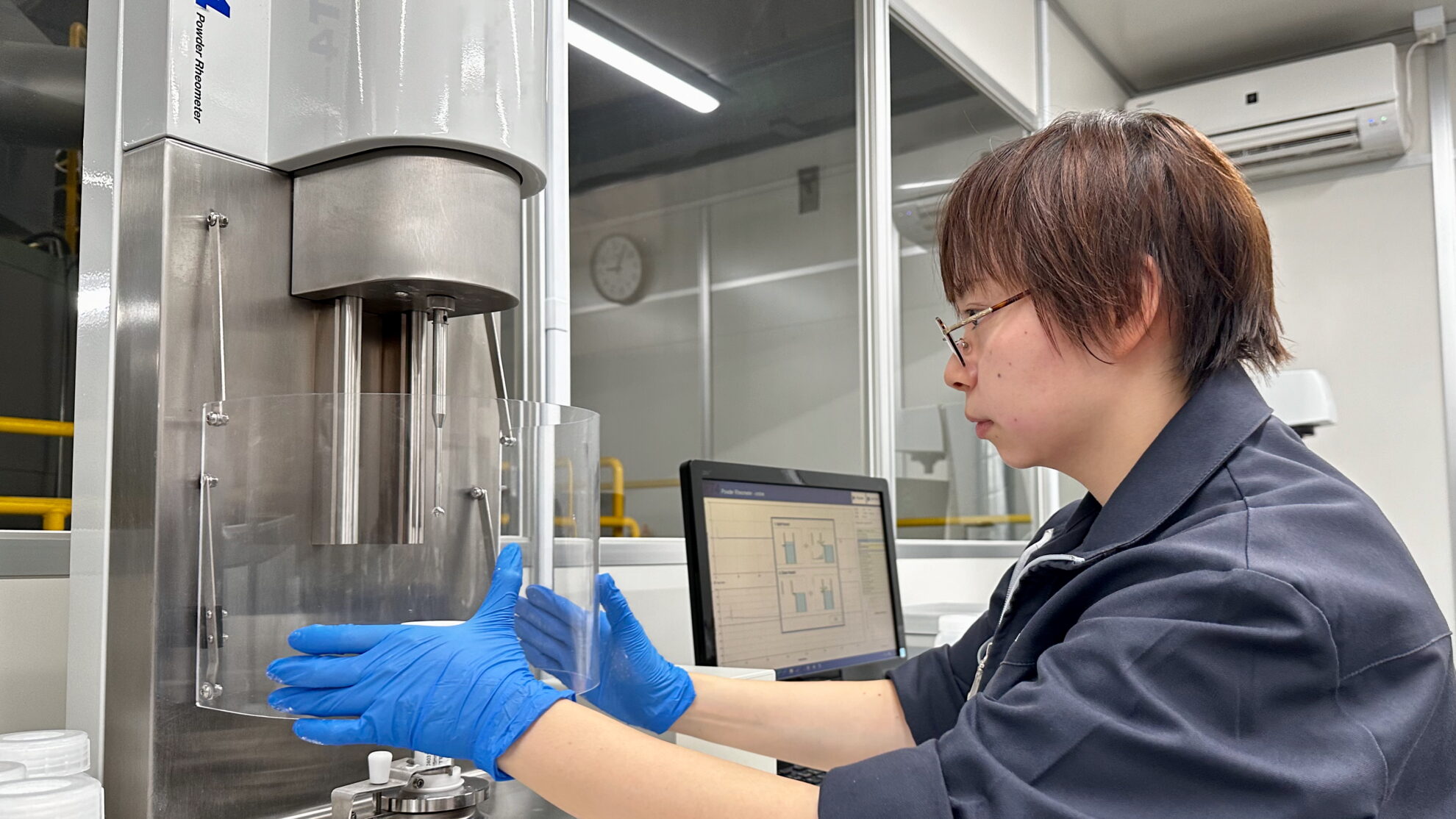

The main parameters for quality control of powder products are particle size distribution, bulk density, and moisture content. In addition, flowability, wettability, solubility, color, and particle surface properties related to taste may also be included. Regarding particle size, larger particles have good flowability and are easy to fill into containers, so they have a high bulk density. The opposite is true for small particles, which have a low bulk density. If the bulk density value is unstable, the stability during product filling will decrease. Large particles have a small specific surface area, which means that moisture does not escape easily during drying, and the moisture content tends to be high. Small particles have a large specific surface area, which means that moisture escapes easily, resulting in a low moisture content. On the other hand, highly hygroscopic powders may re-absorb moisture contained in the exhaust air, resulting in small particles with a high moisture content and large particles with a low moisture content.

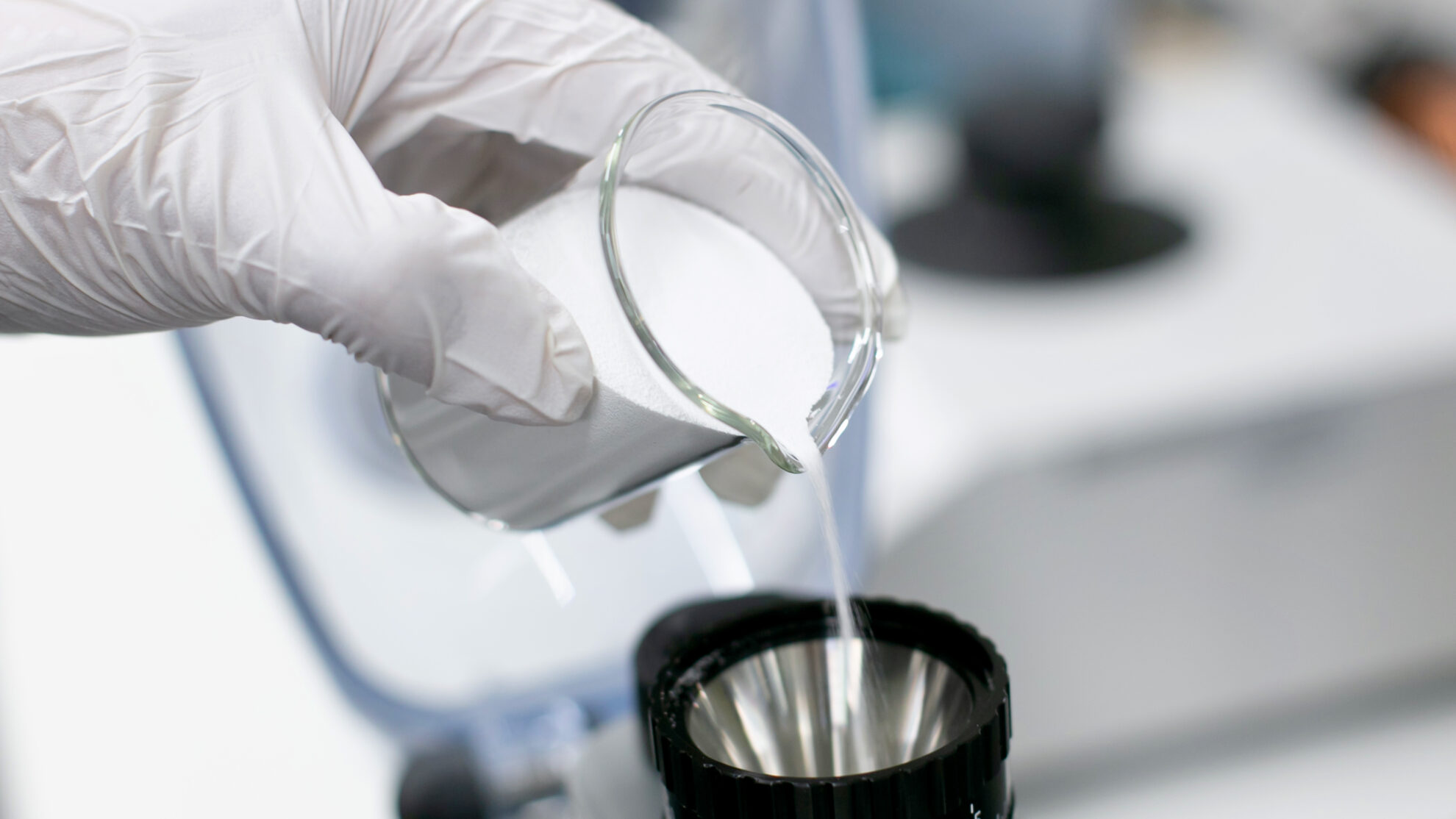

For raw materials, the concentration, presence or absence of additives, and the amount of additives added are key indicators. Increasing the concentration of the raw material reduces the amount of water that evaporates per unit time, thereby improving production efficiency. However, the concentration of the raw material affects the particle size and density of the product, so an appropriate value must be determined. For raw materials containing low-molecular-weight sugars, the tendency for adhesion is high, so it is important to optimize the additives and their amount. If the dried product continues to adhere or accumulate in the process, the powder will be exposed to high temperatures for a long time, which may cause discoloration due to heat effects. In addition, if it is necessary to improve wettability or solubility, additives such as superabsorbent polymers (SAPs, e.g. sodium polyacrylate) or silica may be used.

One of our loyal customers, a collagen peptide manufacturer, has continued to increase its spray drying production capacity to meet growing demand since its first spray dryer installation tens of years ago. From small scale lab spray dryers to multiple large production plants, the customer has always selected our spray dryers until now. The customer has expanded its spray drying capacity together with applying our updated new technologies in its process year by year. The adoption of new technologies are not only applied to new plants, but also to its existing plants, enabling continuous improvements of production efficiency and productivity.

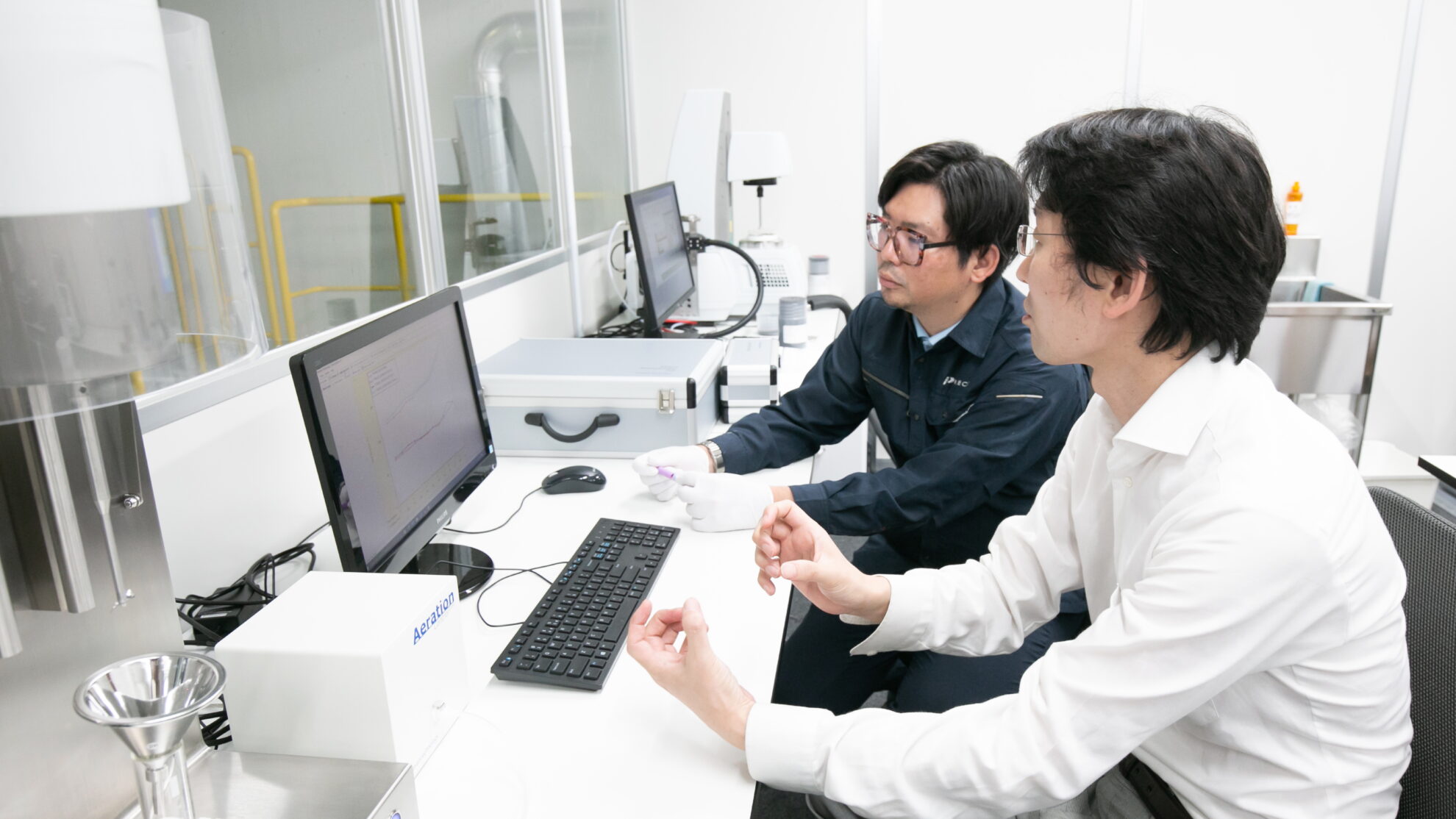

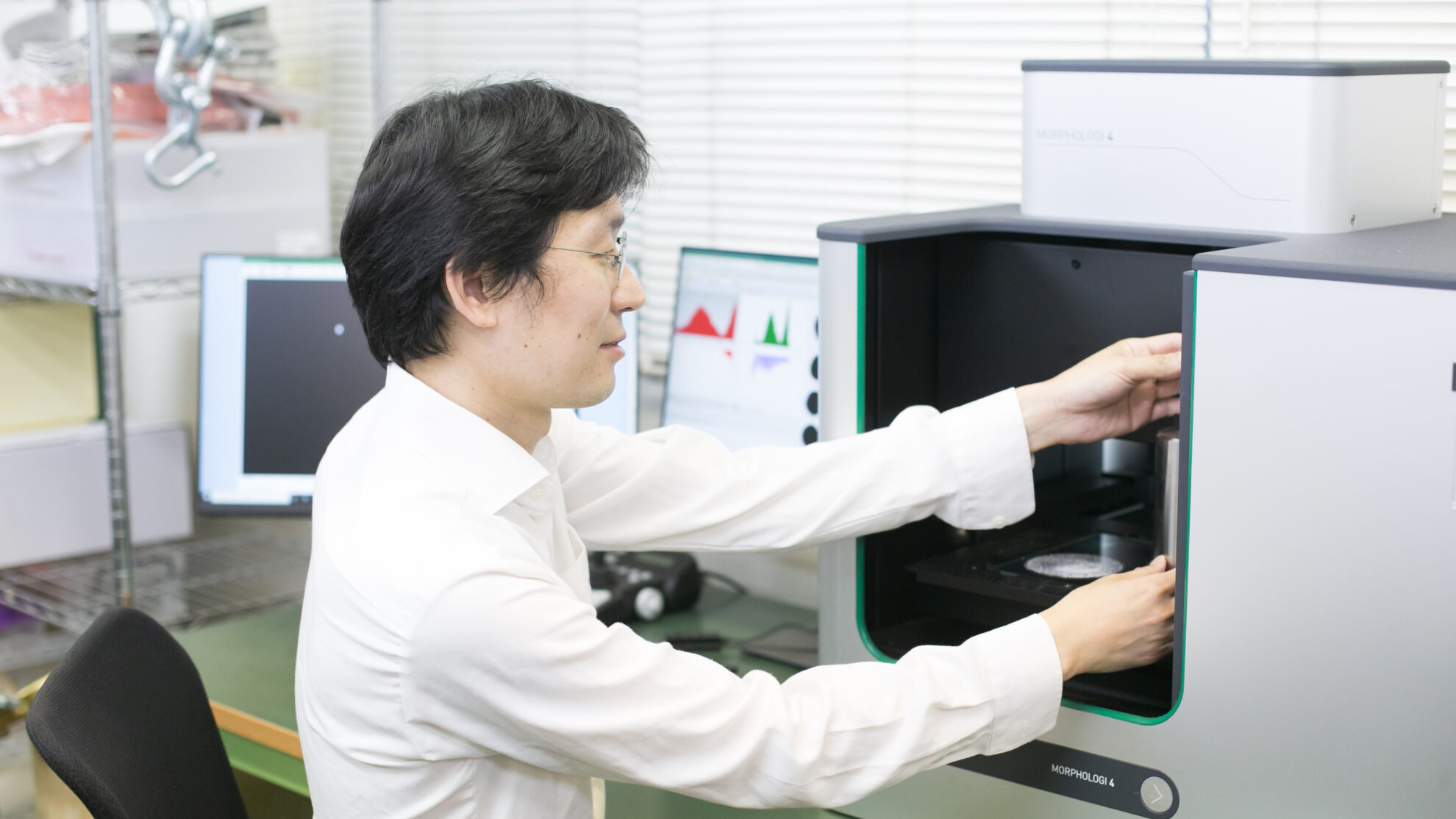

For the customer’s R&D, in addition to its in-house operation, the customer also collaborates with our Powder Technical Center to increase its research efficiency. In daily research, we contribute to our customer’s development team by providing advice on operating conditions, etc. We also supplement our analytical measurement facilities that the customers do not own, making it possible to evaluate the products in multiple ways. Through our long-term strong partnership with the customer, we contribute to increasing customer value not only by installing our processes, but also by improving production capacity and efficiency, and supporting their R&D.

Our spray dryers have a proven track record in the spray drying process of collagen peptides. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.