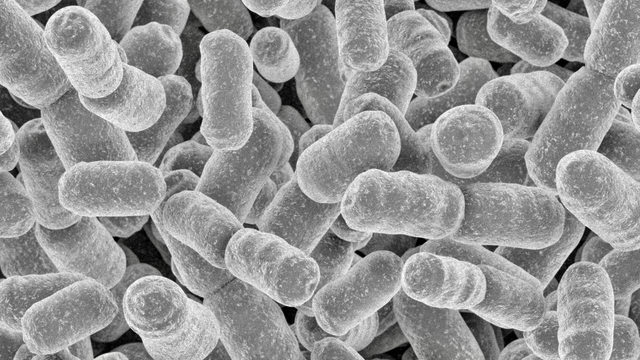

In recent years, probiotics, which coexist with beneficial bacteria to promote health, have been attracting attention from the perspective of preventive medicine. Probiotics are microorganisms that are beneficial to the health of humans and animals. The definition proposed by British microbiologist R. Fuller in 1989 as “live bacteria that benefit the host animal by improving the balance of intestinal microorganisms” and the widely accepted definition set forth in the guidelines of the FAO (Food and Agriculture Organization of the United Nations) and WHO (World Health Organization) as “live microorganisms that, when ingested in appropriate amounts, have a beneficial effect on the health of the host animal” are widely accepted.

Typical probiotics include lactic acid bacteria and bifidobacteria. These microorganisms are said to have beneficial effects such as maintaining a good balance of intestinal flora, reducing bad bacteria in the intestines, alleviating constipation and diarrhea, suppressing allergies, and improving immune function. Probiotic foods include fermented milks such as yogurt, as well as fermented foods such as natto and miso. It is important for probiotics that live bacteria reach the intestines alive, without being killed by gastric juices or bile. Also, different types of bacteria function in different places in the body. For example, lactic acid bacteria mainly function in the small intestine, while bifidobacteria and butyric acid bacteria function in the large intestine.

In addition to probiotics, it is also said to be good to consume foods that serve as a nutrient source for beneficial bacteria, known as prebiotics, such as oligosaccharides and dietary fiber. It has been reported that consuming prebiotics provides nutrients to beneficial bacteria and helps the growth of beneficial bacteria, thereby maintaining a healthy intestinal environment. Recently, synbiotics, which involve consuming a balanced amount of prebiotics and probiotics, have also been attracting attention.

Probiotic products are mainly sold as solid foods such as yogurt, liquid drinks, or dried powders (including tablets and capsules). Dried powders of lactic acid bacteria and bifidobacteria have a smaller mass and volume than liquid products, which helps reduce transportation costs. In addition, as they are dried products, they can be stored for a long period of time. Spray dryers are used in the process of manufacturing dried powders of lactic acid bacteria and bifidobacteria. Dried powder products of lactic acid bacteria and bifidobacteria produced industrially using spray dryers are used in pharmaceuticals such as intestinal regulators, health foods, supplements, and as intermediate ingredients added to processed foods and beverages.

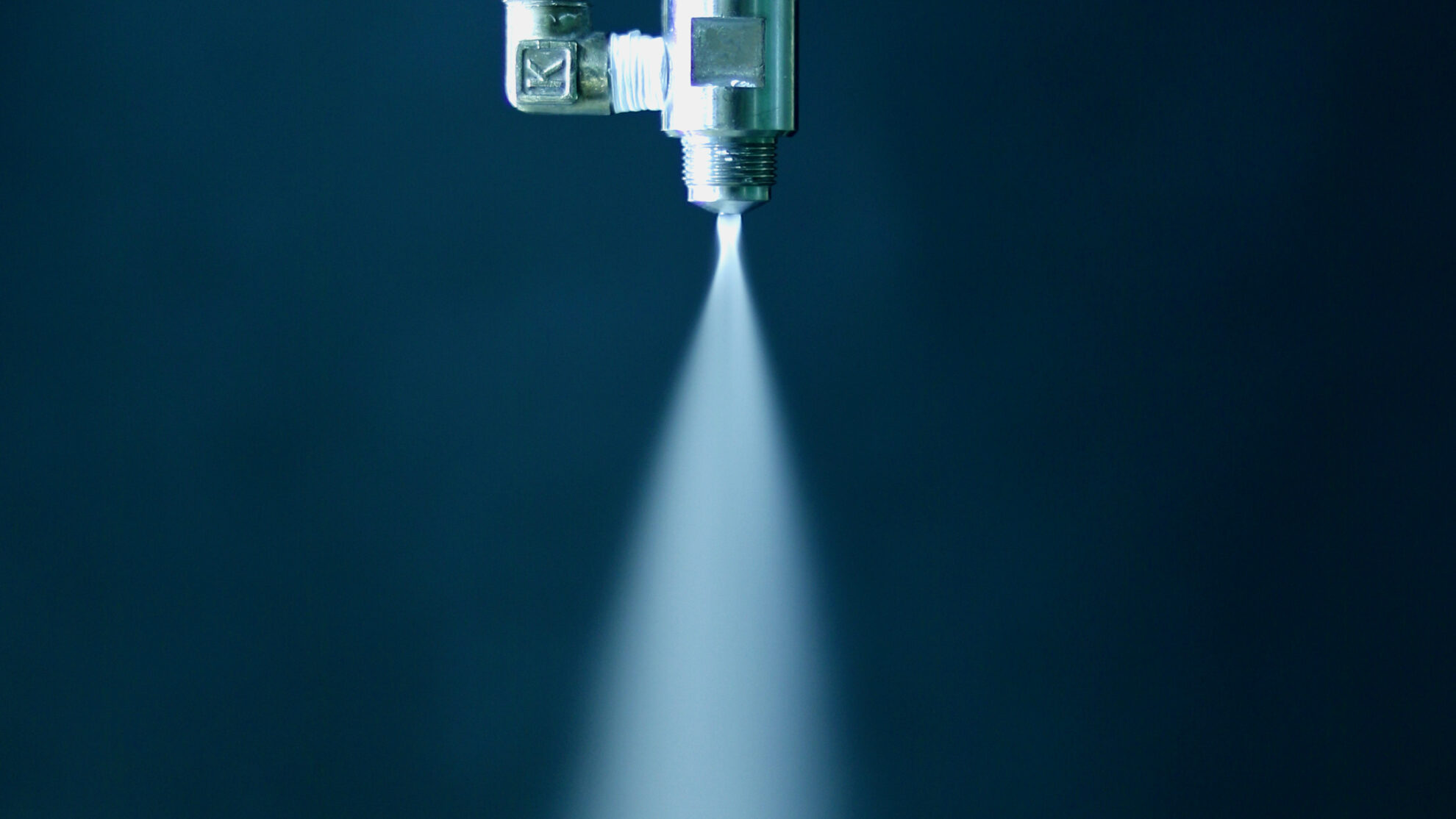

A properly designed spray dryer is required for spray drying of lactic acid bacteria and bifidobacteria. When spray drying live bacterial liquid material, the viable bacteria rate is one of the most important quality control factors. The operating conditions are generally such that the drying gas inlet temperature is 130 – 180°C and the outlet temperature is 60 – 90°C, allowing for gentle drying. Spray dryers increase drying capacity by increasing the drying gas temperature and the temperature difference between the inlet and the outlet temperatures ( ΔT ), improving production efficiency per unit time. However, if the temperature conditions are increased, the viability of bacteria will decrease due to heat effect. To prevent the bacteria from heat, it is necessary to lower the process temperature setting while taking productivity into consideration. On the other hand, lowering the process temperature increases the moisture content of the product, increasing the risk of product adhesion and powder agglomeration during the spray drying process. For this reason, it is important to determine the optimal conditions of inlet/outlet temperatures and process gas volume, and balance the product quality with production efficiency and operational stability. In addition to using atmospheric air as the process gas, an inert gas such as nitrogen may be used in the case of bacterial liquids that do not tolerate oxidation.

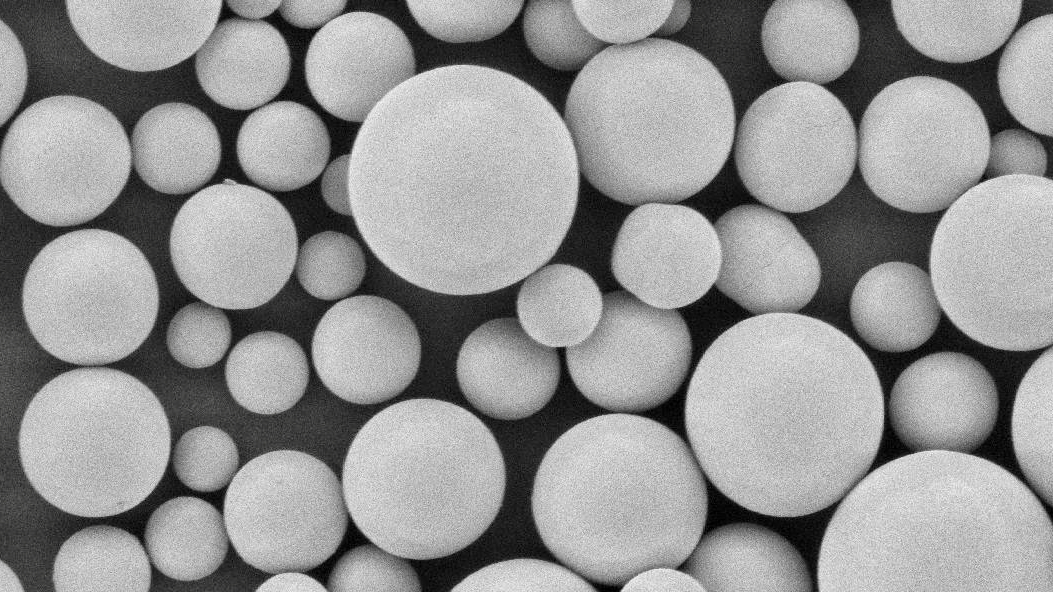

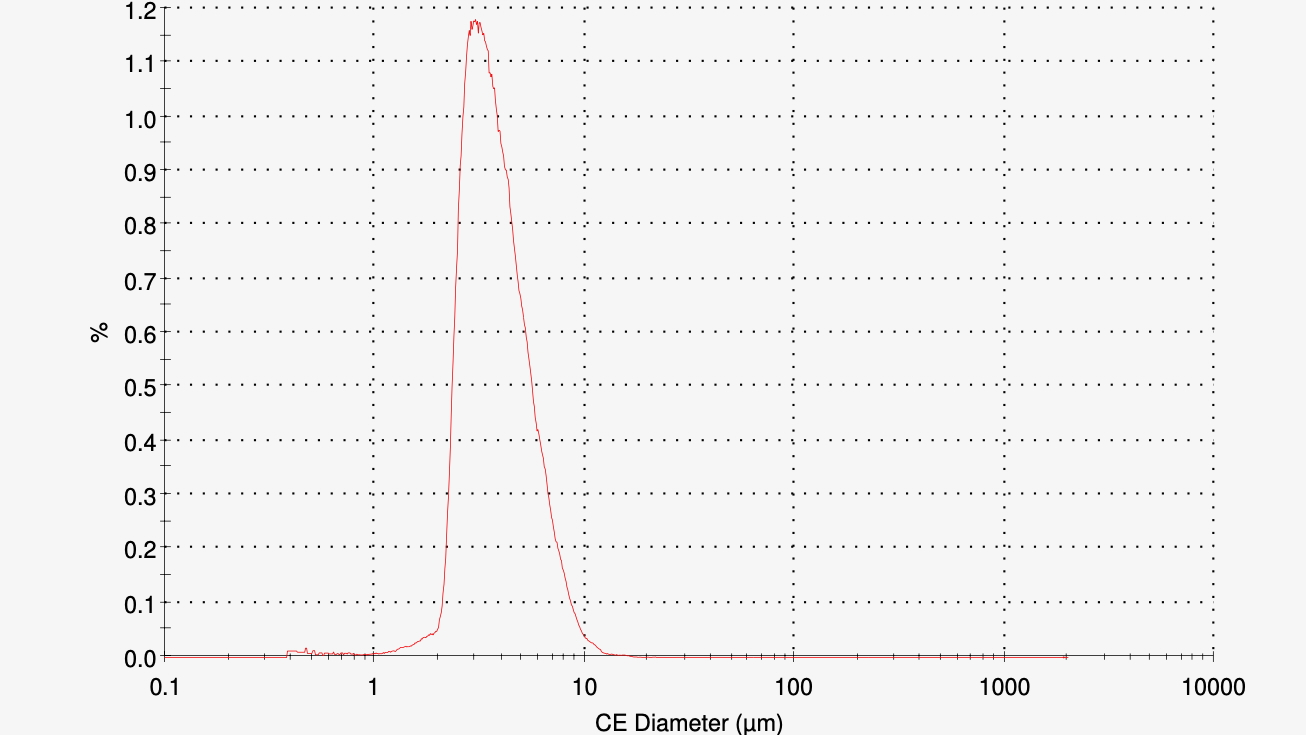

Regarding particle size, the particle diameter may be controlled to be small, taking into account the viable rate. Dry powders for pharmaceuticals and foods generally tend to have a high bulk density, as fluidity and packing properties must be within an appropriate range. On the other hand, for bacteria, the viable rate must also be taken into consideration. Reducing the droplet diameter increases the surface area per unit volume of the droplets, improving the contact efficiency with the drying gas. Therefore, if the process temperature conditions are the same, smaller droplets require less time to dry, which reduces the thermal impact and prevents the death or damage of bacteria. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. When selecting an atomization method, not only the droplet size but also the effects of physical contact and friction must be taken into consideration.

To maintain the viability rate while achieving stable, highly efficient production, it is necessary to design an appropriate spray dryer by optimizing the raw materials, process flow, operating conditions, and the quality of the final powder product. The main parameters for controlling the quality of powder products are particle size distribution, bulk density, and moisture content. In addition, flowability, wettability, solubility, color, and particle surface properties related to taste may also be included.

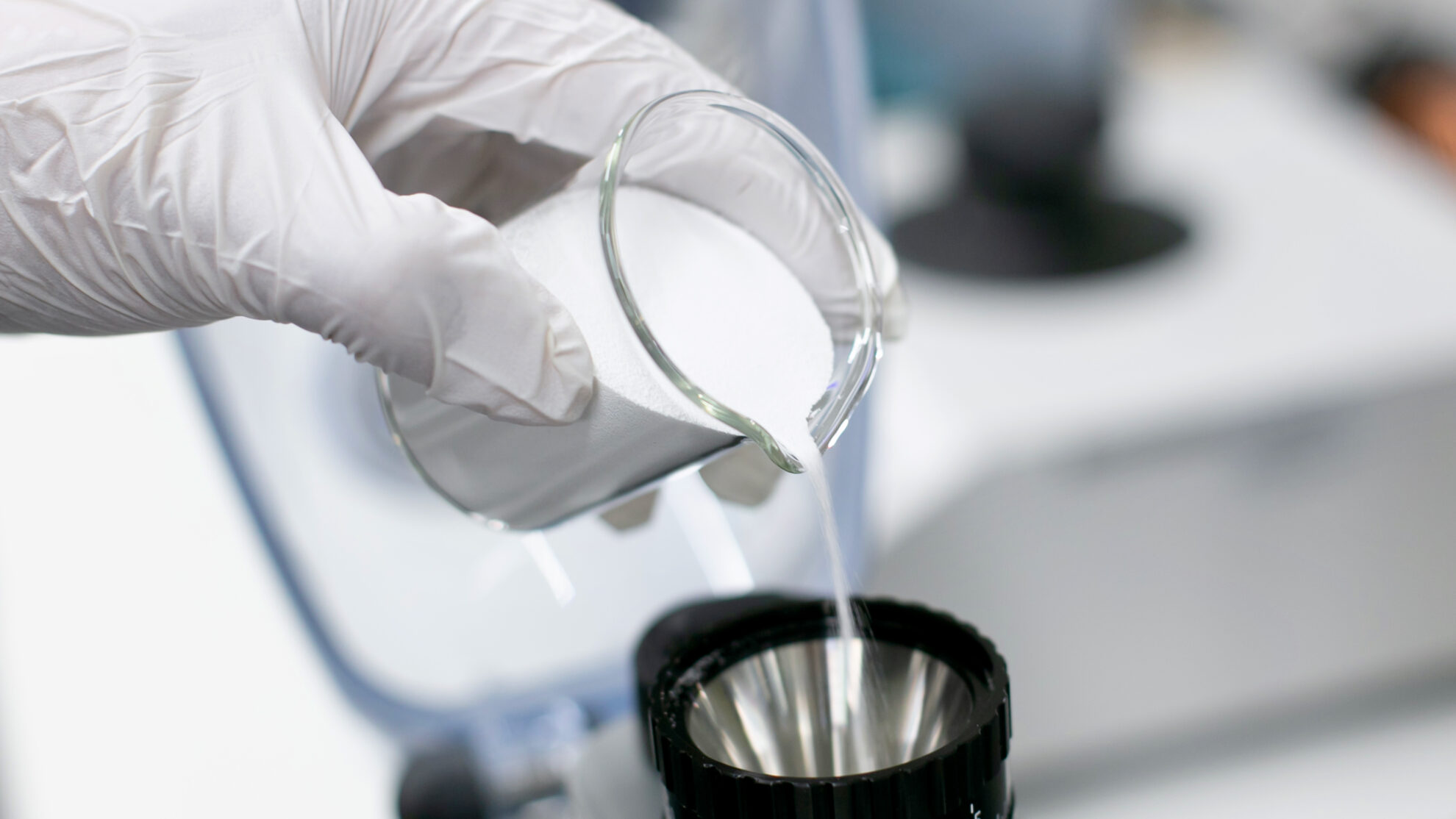

For raw materials, the concentration, presence or absence of additives, and the amount of additives added are key indicators. Increasing the concentration of the raw material reduces the amount of water that evaporates per unit time, thereby improving production efficiency. However, the concentration of the raw material affects the particle size and density of the product, so an appropriate value must be determined. In spray drying of live bacterial liquid materials, the original liquid concentration is generally concentrated to about 30% within the viscosity range where stable liquid feed rate is achievable.

Our spray dryers have a proven track record in the spray drying process of live bacterial liquid materials including lactic acid bacteria and bifidobacteria. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation”, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

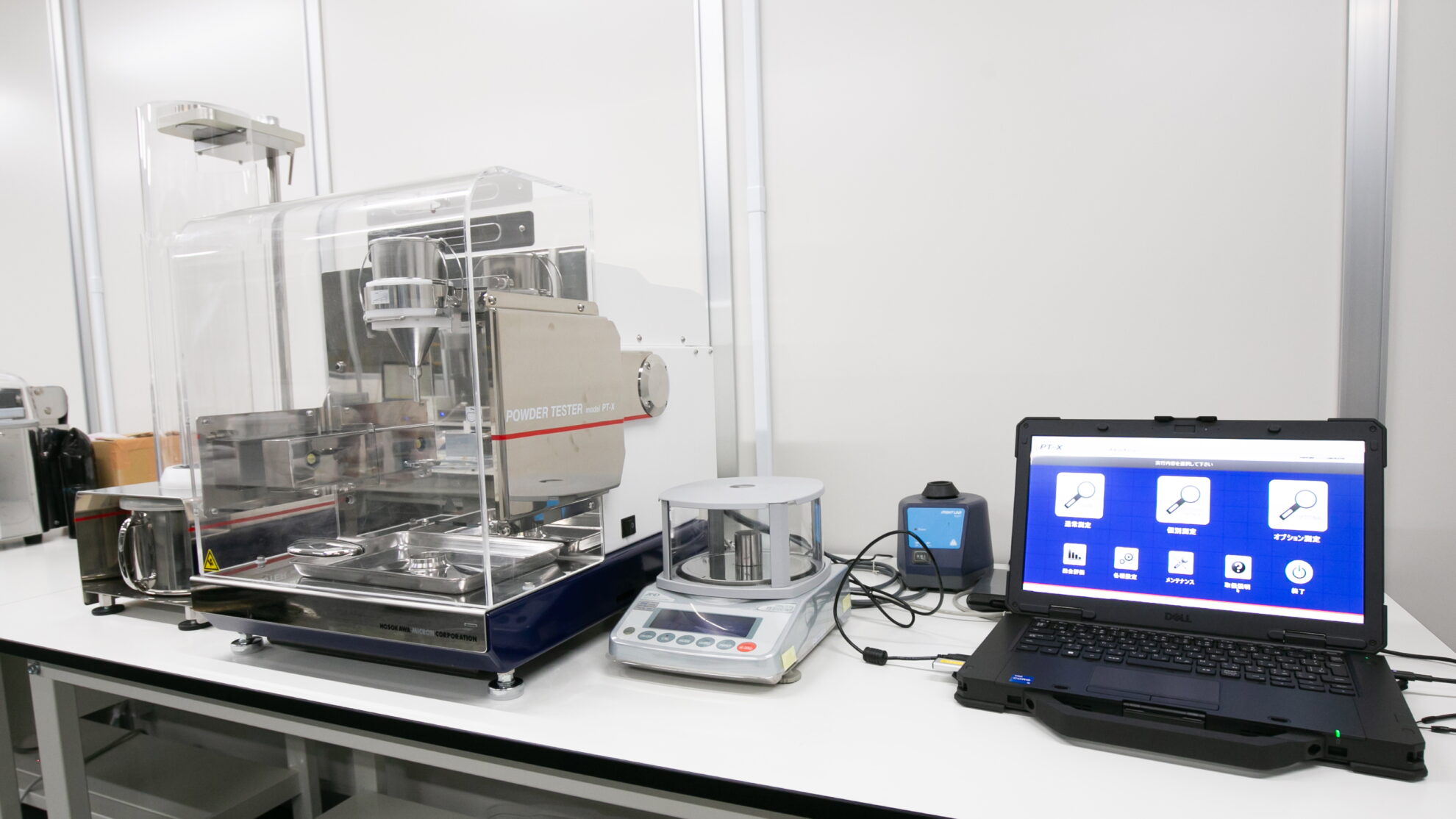

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.