Prebiotics, such as oligosaccharides and dietary fibers, are widely used in a variety of diets because they help promote human health. While probiotics refer to live microorganisms (beneficial bacteria), prebiotics refer to foods that are indigestible and reach the large intestine, where they serve as a nutrient source for beneficial bacteria in the intestine. Taking prebiotics is said to increase the number of beneficial bacteria in the intestines and maintain a good balance of intestinal flora. The resulting proliferation of beneficial bacteria is also said to have effects such as promoting mineral absorption, preventing inflammatory bowel disease and intestinal cancer, and suppressing allergies. Recently, synbiotics, which involve taking a balanced amount of prebiotics and probiotics, have also been attracting attention.

It is known that taking oligosaccharides increases the number of bifidobacteria in the body. Oligosaccharides include lactosucrose, galactooligosaccharides (GOS), fructooligosaccharides (FOS), and mannan oligosaccharides (MOS), and are widely used as active ingredients in functional foods and pet foods. As far back as 1899, Dr. Tissier of the Pasteur Institute discovered bifidobacteria in the stool of breastfed infants, which led to advances in research into intestinal bacteria. It was discovered that oligosaccharides are the growth factor for bifidobacteria in breast milk, and research into oligosaccharides has progressed rapidly since then. Currently, demand for oligosaccharides continues to expand, with the market forecast to grow at a rate of 6.3% per year and reach US$2.5 billion by 2029.

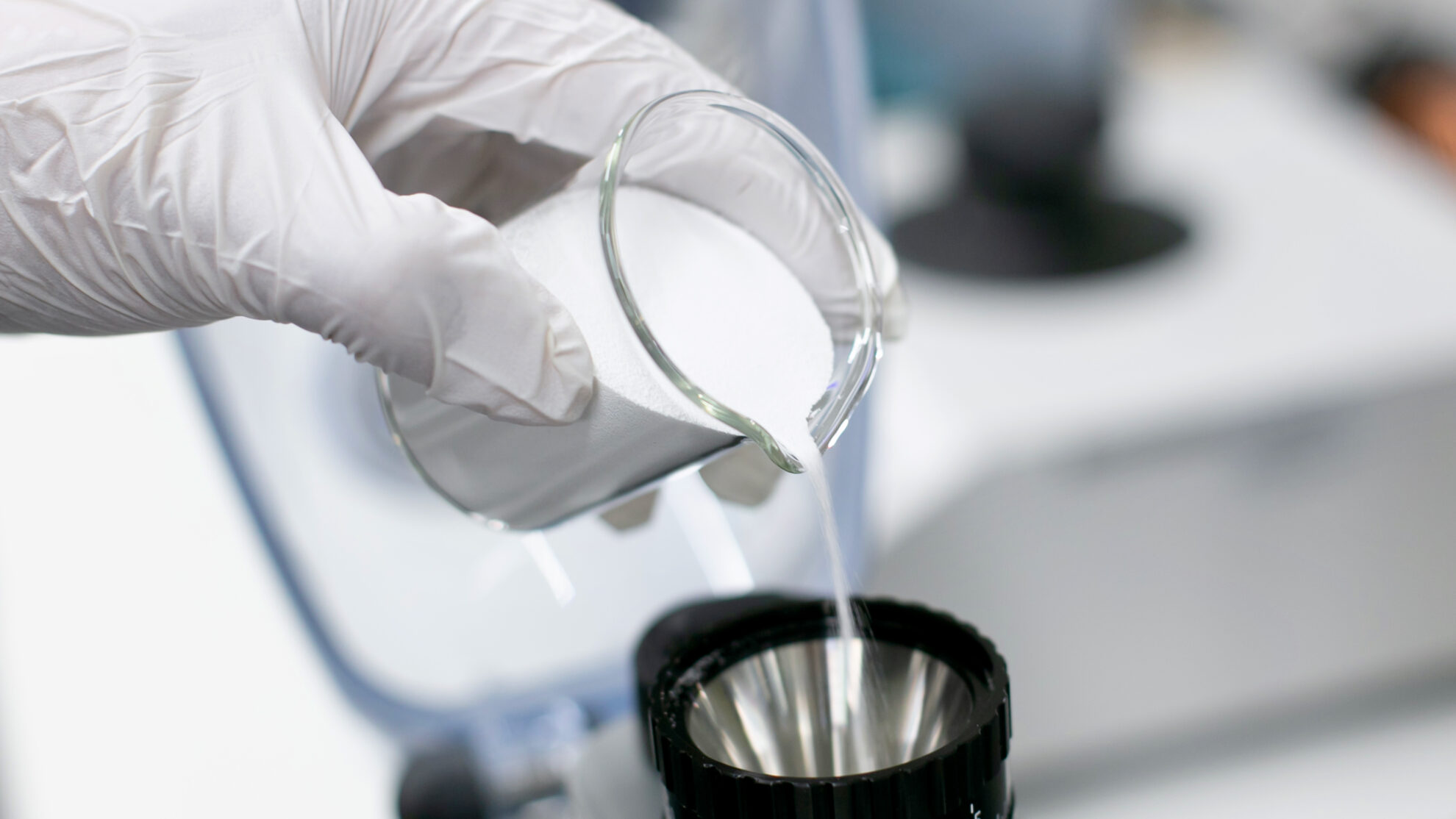

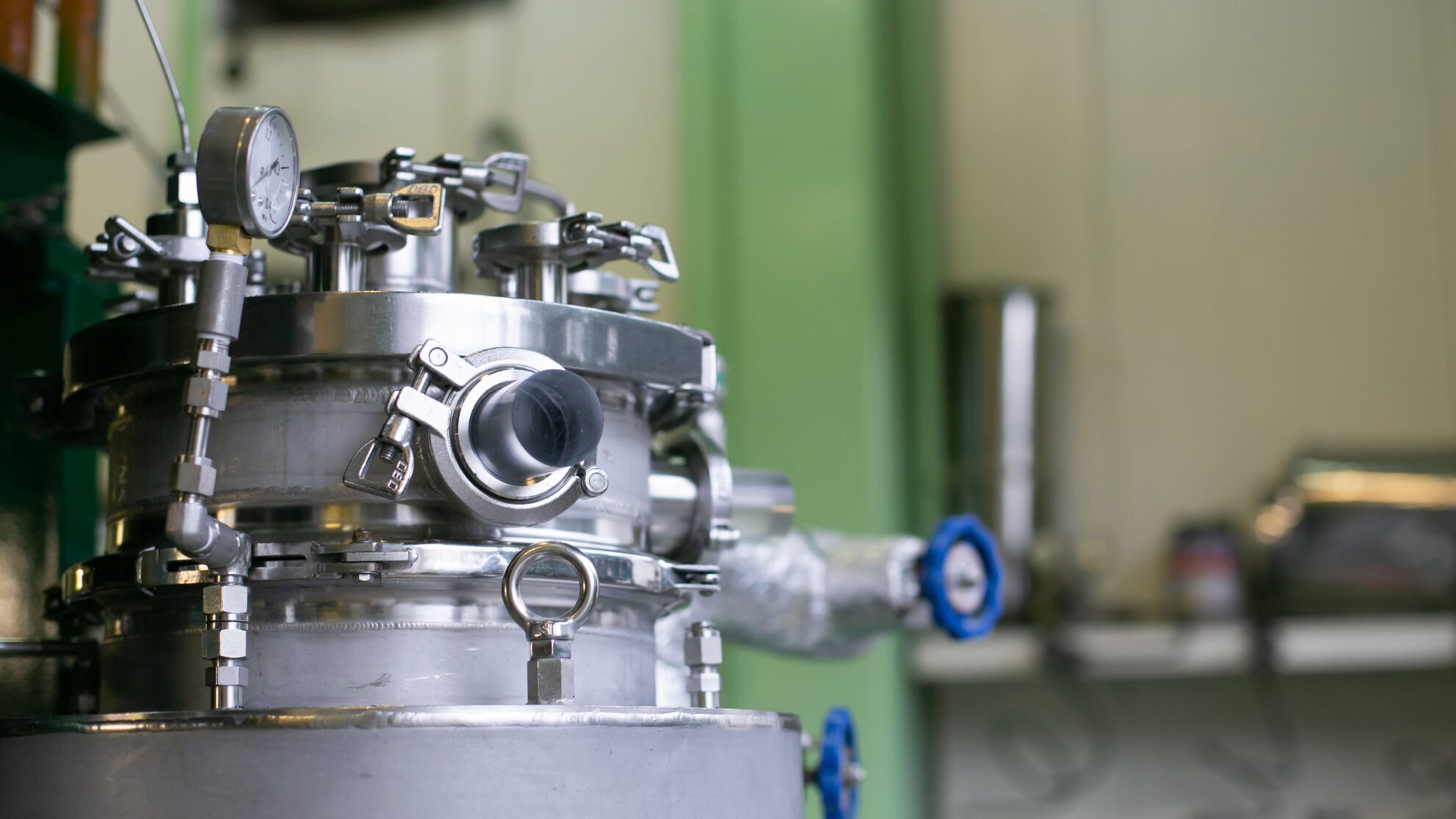

Oligosaccharides are mainly sold as dry powders or liquid syrup. Dried powders have a smaller mass and volume than liquids, which reduces transportation costs. In addition, because they are dry products, they can be stored for a long period of time. Spray dryers are used in the manufacturing process of dried oligosaccharide powders. Dried oligosaccharide powders produced industrially using spray dryers are used in processed foods such as infant formula and bakery products, as intermediate ingredients added to dairy products and beverages, and as pharmaceutical ingredients.

Human milk oligosaccharides (HMOs) are also attracting attention. HMOs are natural components found in breast milk and may help develop the immune system and improve cognitive function in infants. They have also been shown to be useful in reducing the risk of infections and allergies. HMOs are also important as prebiotics. HMOs, which selectively nourish intestinal bacteria such as bifidobacteria and promote the growth of beneficial bacteria, are attracting growing interest in general healthcare to support health. HMOs are components that are rarely found in cow’s milk or the milk of other mammals, which are the main ingredients in powdered milk. Because they are difficult to extract from nature, a stable manufacturing process has been sought. In recent years, industrial manufacturing methods using enzyme reactions are beginning to be established. In the future, it is expected that there will be an increase in products that effectively incorporate HMOs, such as powdered milk with a composition similar to that of breast milk.

Spray drying of oligosaccharides requires a properly designed spray dryer, as mixing low molecular weight ingredients, such as fructose-containing monosaccharides and oligosaccharides, can result in sticky and hygroscopic dried powders. If the spray dryer process is not designed appropriately, problems such as a decrease in product recovery rate due to the dried product adhering to the process interior, powder agglomeration, or re-absorption of moisture contained in the exhaust gas from the process may occur. In order to achieve highly efficient and stable production, it is important to appropriately design the spray drying process, taking into consideration the raw materials, process flows, operating conditions, and even the quality of the final powder products.

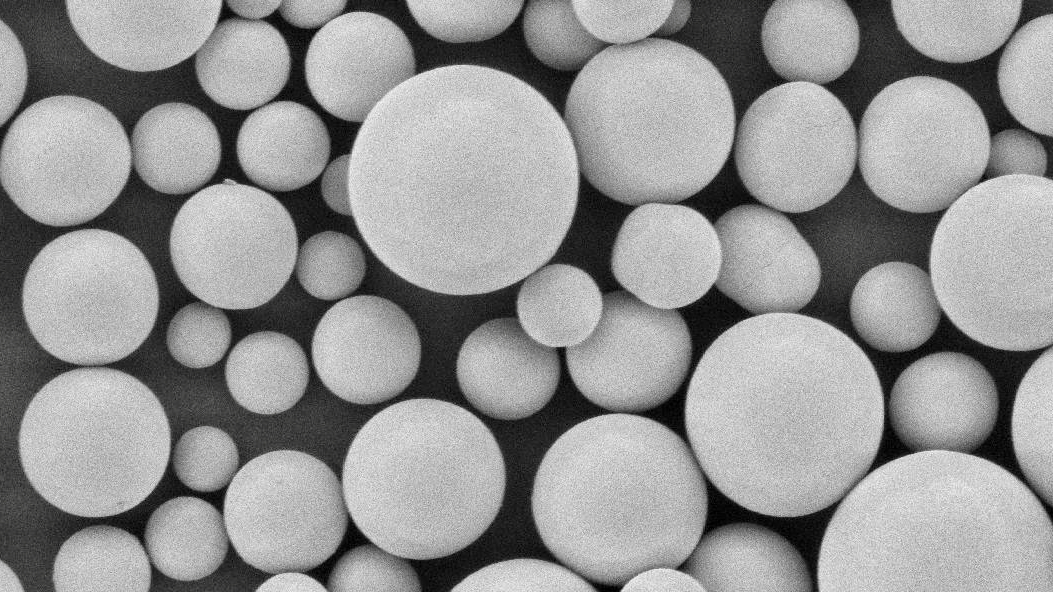

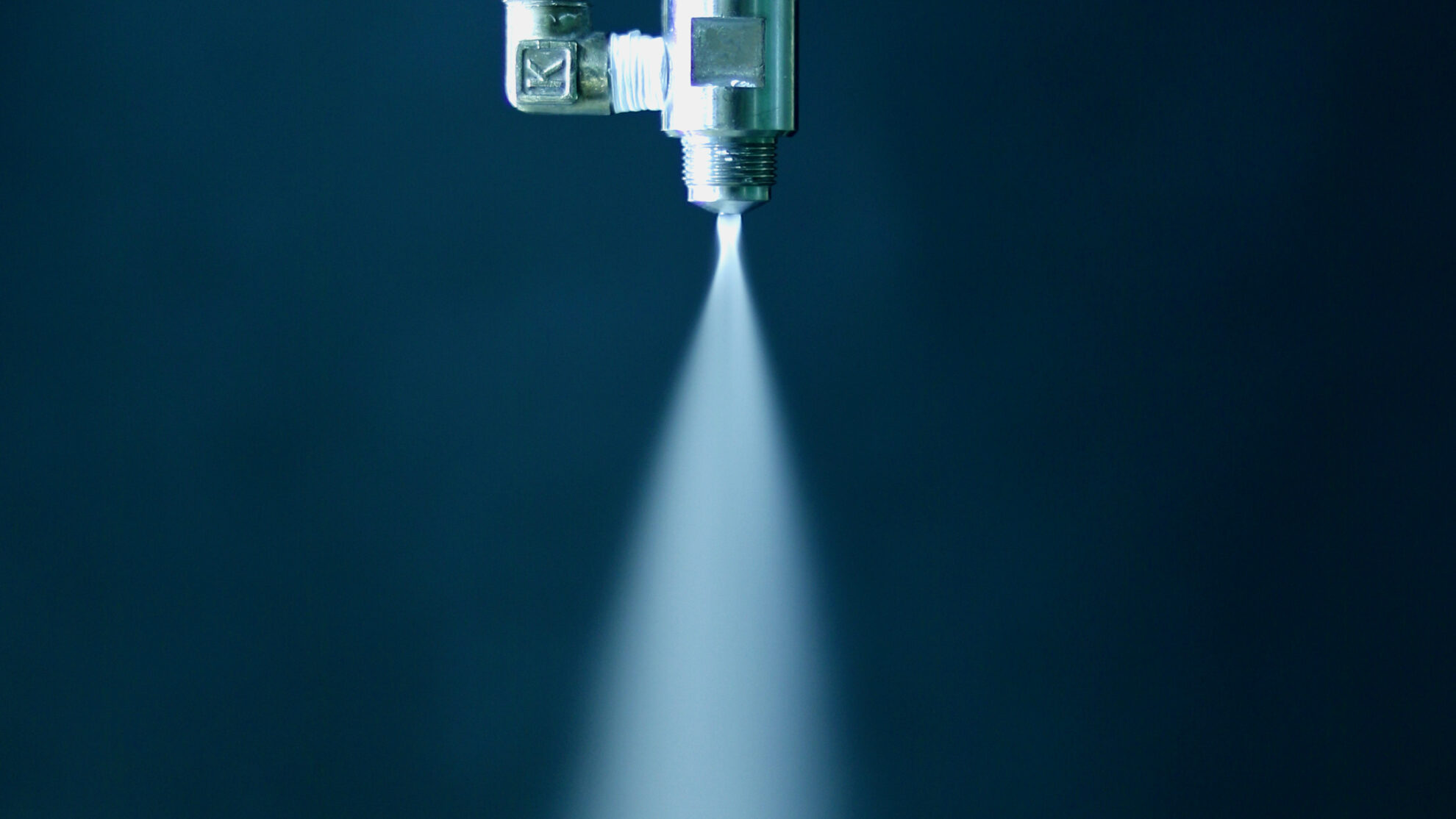

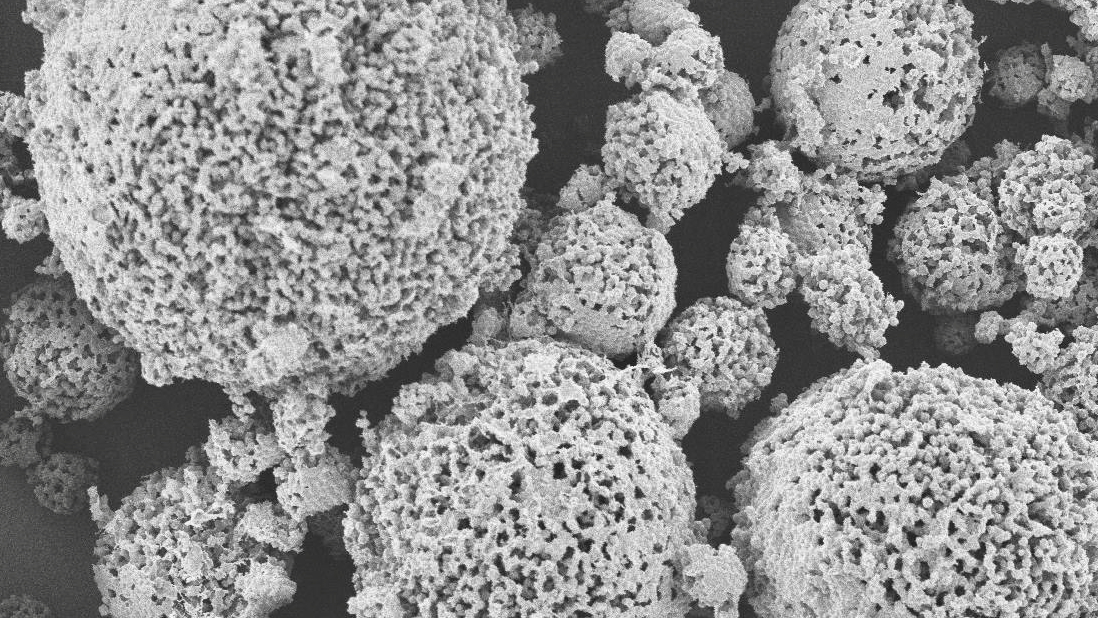

Spray drying of oligosaccharides is generally performed at a low drying temperature for gentle drying. Under low-temperature operating conditions, the liquid material dries slowly, which tends to result in a higher bulk density. On the other hand, under high-temperature conditions, the droplets dry in a short time, which accelerates the formation of an outer shell on the particles. This can result in the particles swelling, bursting, or becoming hollow due to internal evaporation. The moisture content is higher under low-temperature conditions and lower under high-temperature conditions. Liquid atomization methods can be selected from rotary atomizers, two-fluid nozzles, pressure nozzles, and ultrasonic nozzles. When selecting an atomization method, not only the size of the atomized droplets but also the effects of physical contact and friction must be taken into consideration.

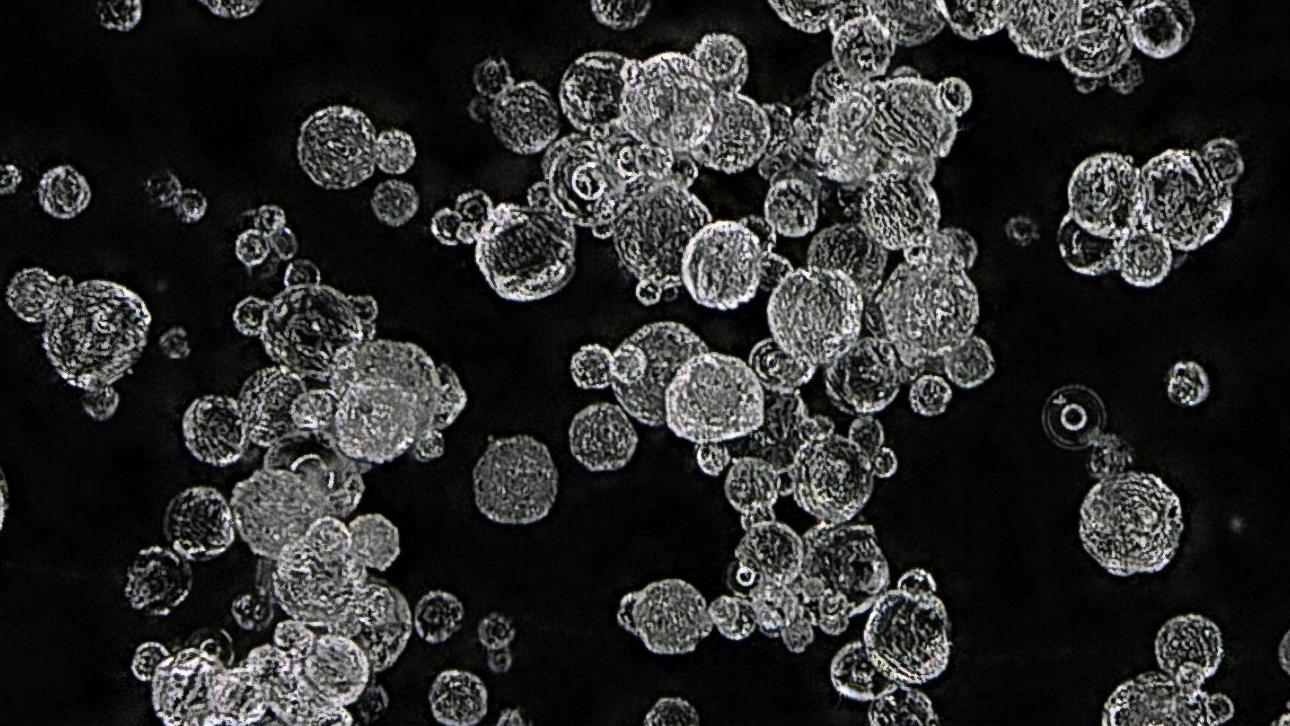

The main parameters for quality control of powder products are particle size distribution, bulk density, and moisture content. In addition, flowability, wettability, solubility, color, and particle surface properties related to taste may also be included. Regarding particle size, larger particles have good flowability and are easy to fill into containers, so they have a high bulk density. The opposite is true for small particles, which have a low bulk density. If the bulk density value is unstable, the stability during product filling will decrease. Large particles have a small specific surface area, which means that moisture does not escape easily during drying, and the moisture content tends to be high. Small particles have a large specific surface area, which means that moisture escapes easily, resulting in a low moisture content. On the other hand, highly hygroscopic powders may re-absorb moisture contained in the exhaust air, resulting in small particles with a high moisture content and large particles with a low moisture content.

For raw materials, the concentration, presence or absence of additives, and the amount of additives added are key indicators. Increasing the concentration of the raw material reduces the amount of water that evaporates per unit time, thereby improving production efficiency. However, the concentration of the raw material affects the particle size and density of the product, so the optimal amount must be determined. For raw materials containing low-molecular-weight sugars, the tendency for adhesion is high, so it is important to optimize the additives and their amount. If the dried product continues to adhere or accumulate in the process, the powder will be exposed to high temperature environment for a long time, which may cause discoloration due to heat effects. In addition, if it is necessary to improve wettability or solubility, additives such as superabsorbent polymers (SAPs, e.g. sodium polyacrylate) or silica may be used.

Our spray dryers have a proven track record in the spray drying process of oligosaccharides. Based on our accumulated experience and expertise, we design optimal spray drying processes and set operating conditions that meet the required quality. By optimizing the various conditions of the spray drying process, we control powder quality that exceeds customers’ expectations. In addition, our freeze granulator is a brand new powder manufacturing process that may overcome the weaknesses of spray-dried products and freeze-dried pulverized products. Regarding freeze granulation technology, we have introduced more information in “About Freeze Granulation“, “Advantages of Freeze Granulation in Foods, Beverages and Pharmaceuticals (Comparison with Grinded Freeze-Dried Products)” and “High Viable Bacteria Rate – Spray Drying and Freeze Granulation“.

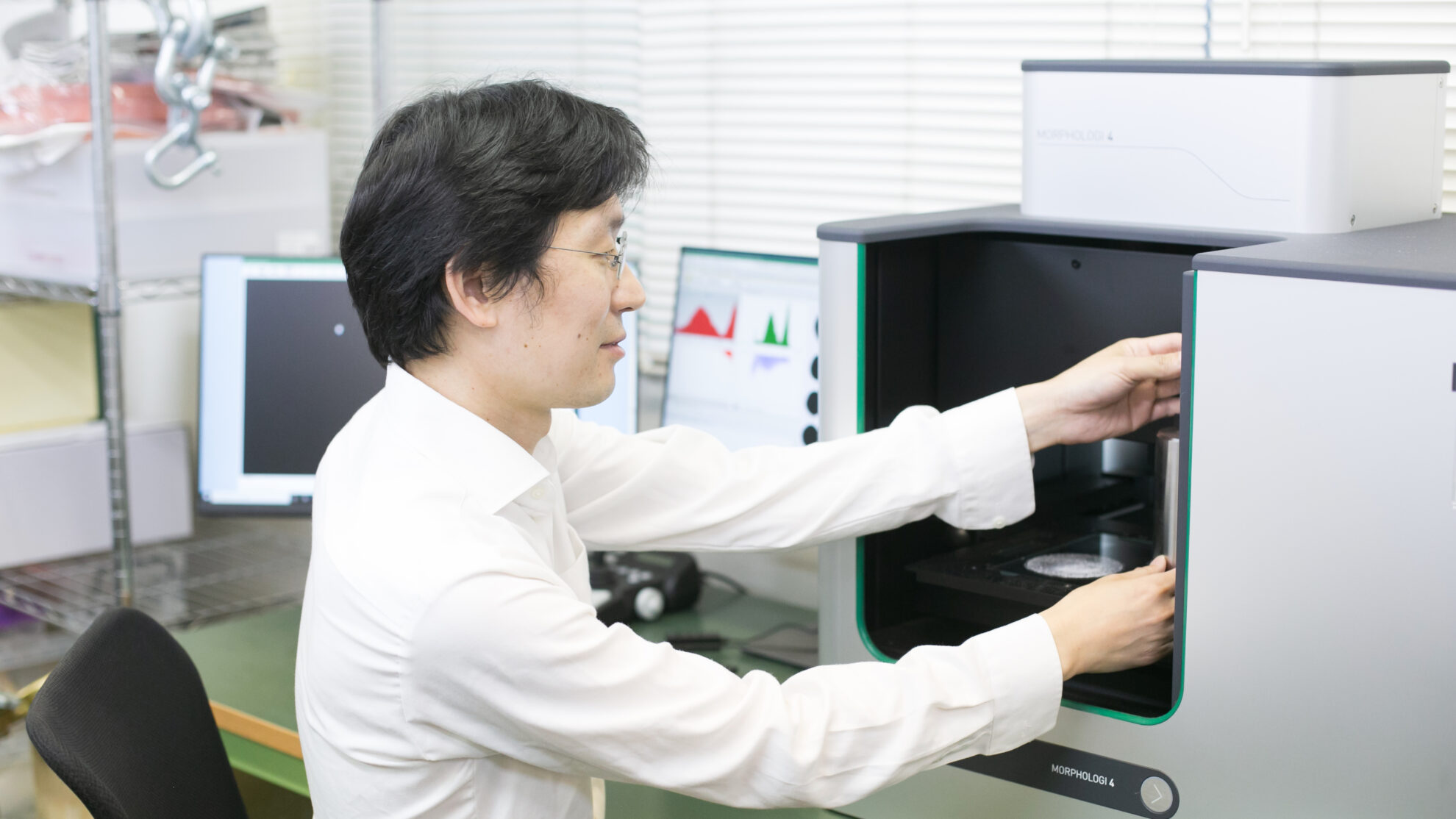

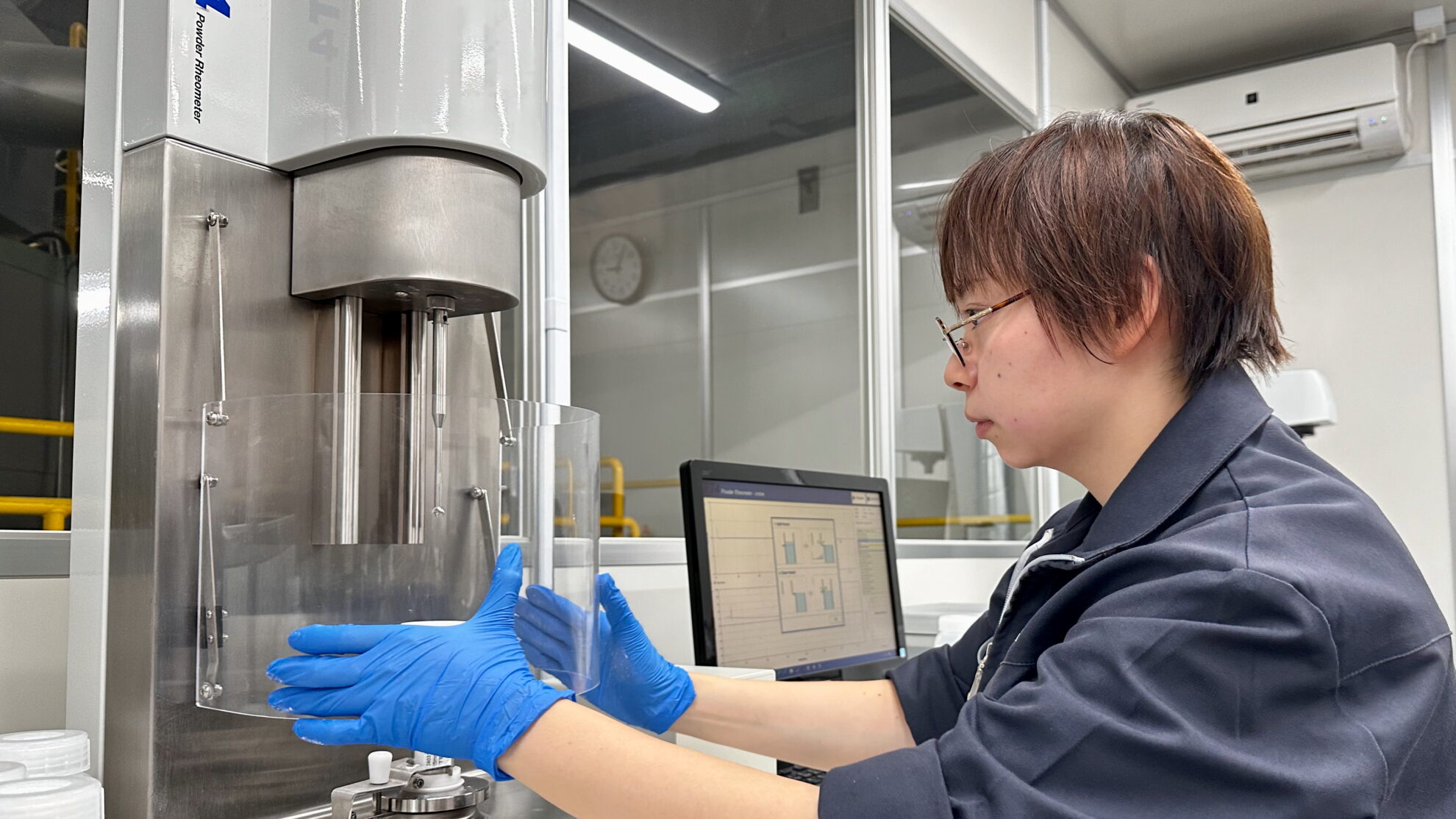

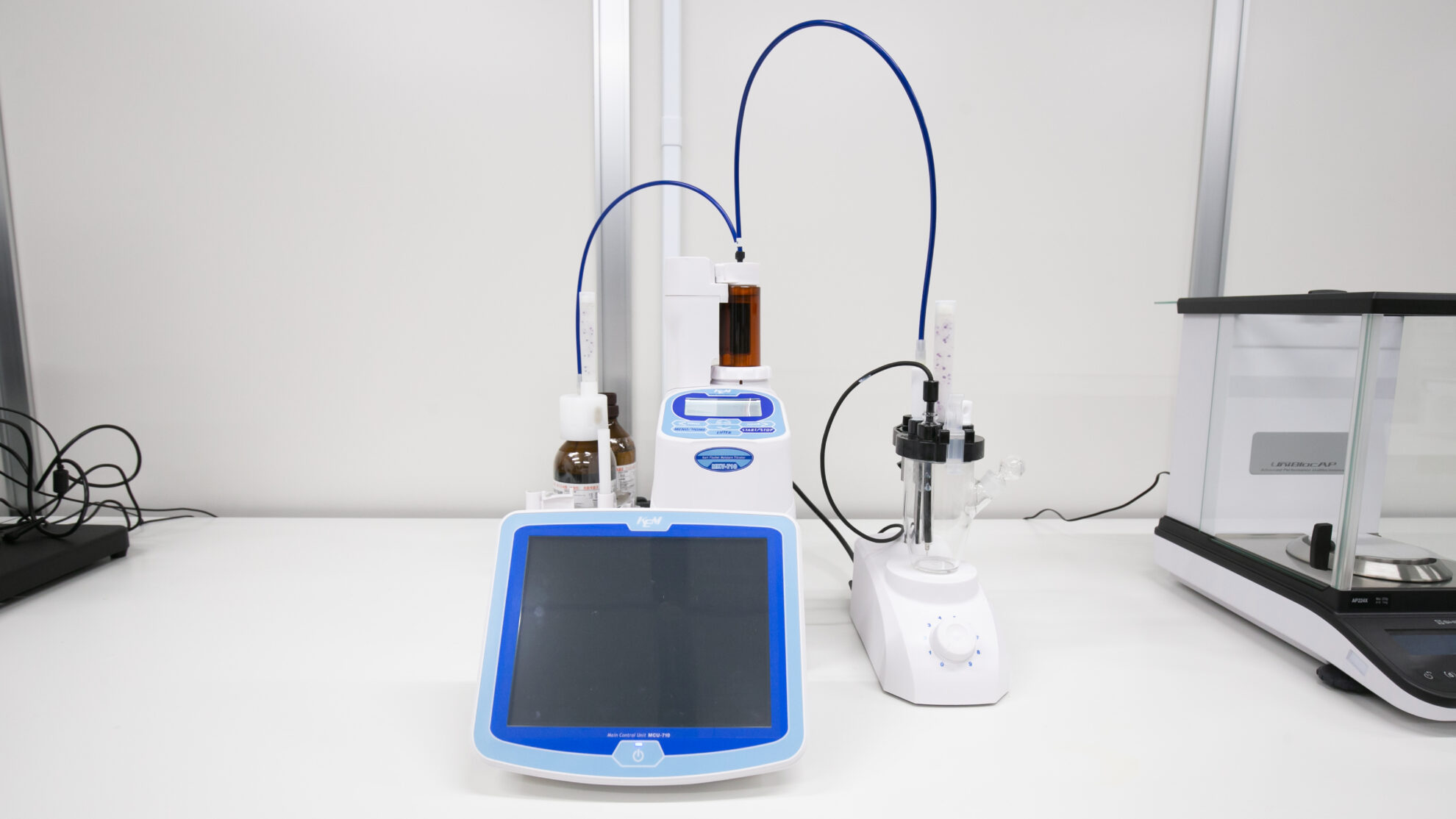

We not only provide powder processing trials for spray drying, spray cooling, and freeze granulation, but also services that include pre- and post-powder processing, such as wet pulverizing, mixing, molding, sintering and freeze-drying. We operate a total of three locations: two Powder Technical Centers in Japan and ASEAN Powder Technical Center in Thailand. Our brand new Powder Technical Center 2 (PTC2), which was newly established in 2023, has one of the largest collections of analytical measurement equipment in Japan. We provide one-stop support for powder processing and analytical measurements (Powder Trials & Analytical Measurements/Contract Powder Processing).

*The contents such as photos shown in this article may differ from the actual projects and may be used as an images.